When navigating the world of home sewing, mastering your machine is essential for achieving the best results. This guide is designed to help you become familiar with your sewing device, ensuring you can make the most of its features and capabilities.

In this section, you’ll discover key insights into how to operate your machine efficiently. From setting up the device to understanding its various functions, this resource will provide you with the necessary knowledge to enhance your sewing experience.

Whether you’re a novice or an experienced sewist, gaining a clear understanding of your machine’s components and their uses will significantly improve your sewing projects. This guide aims to equip you with the skills needed to handle your equipment with confidence.

Setting Up the Elna 6004 Machine

Preparing your sewing device for use involves several essential steps to ensure optimal performance. This process includes configuring various components and settings to achieve accurate and efficient stitching. By following these guidelines, you will be able to get your machine ready for your sewing projects smoothly and effectively.

Initial Setup

- Place the sewing machine on a stable, flat surface to prevent any movement during use.

- Ensure that the machine is properly plugged into a power source and that the power switch is in the off position before starting.

- Install the presser foot and needle as per the device’s specifications to ensure proper function.

- Thread the machine according to the threading guide provided, ensuring all paths are correctly followed.

Testing and Adjustment

- Turn on the machine and test the operation using a scrap piece of fabric to verify that all settings are correctly adjusted.

- Adjust the tension and stitch length according to the fabric type and sewing requirements for optimal results.

- Check the alignment of the needle and thread to avoid any potential issues during sewing.

Basic Operation and Stitch Selection

This section covers the fundamental functions and stitch options available for sewing machines. Understanding these aspects will enhance your ability to perform a variety of sewing tasks efficiently. Here, you’ll learn how to operate your machine effectively and choose the right stitch for different sewing projects.

Understanding the Basics

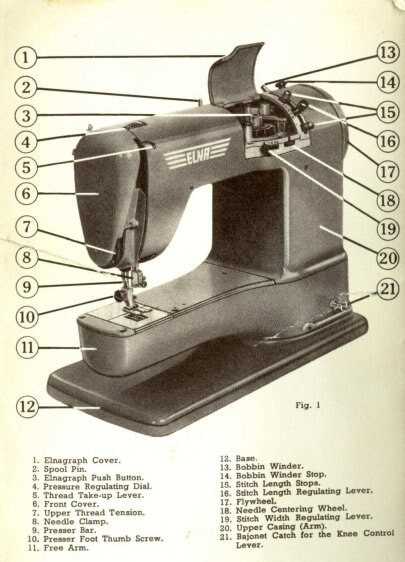

To get started, familiarize yourself with the basic controls of your sewing machine. This includes the needle position, stitch length, and stitch width adjustments. Each of these settings plays a crucial role in achieving precise and high-quality results in your sewing projects.

Choosing the Right Stitch

Selecting the appropriate stitch type is essential for achieving the desired outcome in your sewing work. The machine offers various stitch options, each designed for specific tasks such as hemming, seaming, or decorative stitching. Refer to the stitch guide to make informed choices based on your project requirements.

| Stitch Type | Use |

|---|---|

| Straight Stitch | General sewing, seaming |

| Zigzag Stitch | Stretch fabrics, finishing edges |

| Buttonhole Stitch | Creating buttonholes |

| Decorative Stitch | Adding decorative elements |

Troubleshooting Common Issues

Addressing frequent problems encountered with sewing machines can enhance their performance and extend their lifespan. This section provides solutions for typical malfunctions, ensuring smoother operation and efficient use of the equipment. By identifying and rectifying common issues, users can achieve optimal results and avoid disruptions in their work.

Machine Not Stitching Properly

If the sewing machine is not producing consistent stitches, check the following:

| Possible Cause | Solution |

|---|---|

| Thread Tension Issues | Adjust the tension settings according to the fabric type. Refer to the tension guide in the user manual. |

| Needle Problems | Ensure the needle is correctly installed and not damaged. Replace with a new needle if necessary. |

| Thread Jam | Clear any obstructions in the threading path and ensure the bobbin is properly wound and inserted. |

Machine Making Unusual Noise

Unusual sounds during operation can indicate mechanical issues. Consider these checks:

| Possible Cause | Solution |

|---|---|

| Loose Screws | Tighten any loose screws or components. Regular maintenance checks can prevent this issue. |

| Lack of Lubrication | Apply oil to the machine’s moving parts as per the maintenance guidelines to reduce friction and noise. |

| Foreign Objects | Inspect and remove any debris or foreign objects from the machine’s interior. |

Maintenance and Care Tips

Proper upkeep and regular care are essential for ensuring the longevity and optimal performance of your sewing machine. By following these guidelines, you can maintain its efficiency and avoid common issues.

Regular Cleaning

Cleaning the machine regularly helps prevent dust and lint buildup. Use a soft brush to remove debris from the bobbin area and feed dogs. Additionally, wiping down the exterior with a dry cloth will keep the surface free from grime.

Lubrication and Inspection

Lubrication is crucial for smooth operation. Apply sewing machine oil to the moving parts as recommended by the manufacturer. Regularly inspect the machine for any signs of wear or damage, and address these issues promptly to avoid more serious problems.

Safety Guidelines and Best Practices

Ensuring safety while operating machinery is crucial for both the user and the equipment. Following proper protocols helps prevent accidents, extends the lifespan of the equipment, and ensures smooth operation. Adhering to these guidelines is essential for a safe and effective working environment.

General Safety Precautions

Always inspect the equipment before use to ensure it is in good working condition. Ensure that all guards and safety features are in place and functioning correctly. Avoid wearing loose clothing or accessories that could get caught in moving parts. Keep the work area clean and free from obstructions to prevent tripping hazards.

Operational Best Practices

Read and understand the operating instructions thoroughly before use. Never bypass safety switches or modify the equipment in ways not recommended by the manufacturer. Use the machine only for its intended purpose and follow proper maintenance schedules to keep it in optimal condition. In case of any malfunction, disconnect the power source and seek professional assistance.