Understanding the operation of your equipment is crucial for achieving optimal results in your creative projects. This section is designed to provide you with essential insights and procedures to ensure you utilize your device effectively. Mastering the fundamentals will enable you to enhance your craftsmanship and achieve the desired outcomes in your work.

Each task requires careful attention to detail and adherence to best practices. This guide will walk you through the necessary steps, from setup to execution, empowering you to navigate your activities with confidence. Familiarizing yourself with these processes will help you make the most of your equipment, regardless of your level of experience.

By following the recommendations outlined here, you will be better equipped to manage various applications with precision. Embrace the opportunity to expand your skills and elevate your projects to new heights. The journey towards proficiency begins with a clear understanding of the techniques and practices that underpin successful operation.

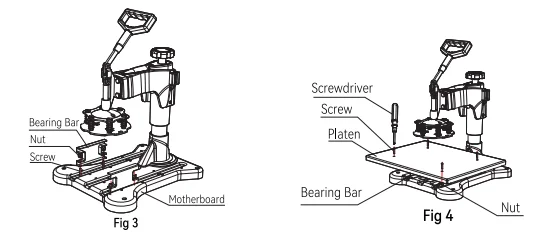

Understanding Your Heat Press Machine

Familiarizing yourself with this versatile device is essential for achieving optimal results in your crafting endeavors. It operates by applying controlled temperature and pressure to various materials, enabling the transfer of designs or images with precision and durability.

Components play a vital role in the functionality of this equipment. The primary parts include the heating element, a base plate, and a pressure mechanism. Each component is designed to work together seamlessly, ensuring even heat distribution and reliable performance.

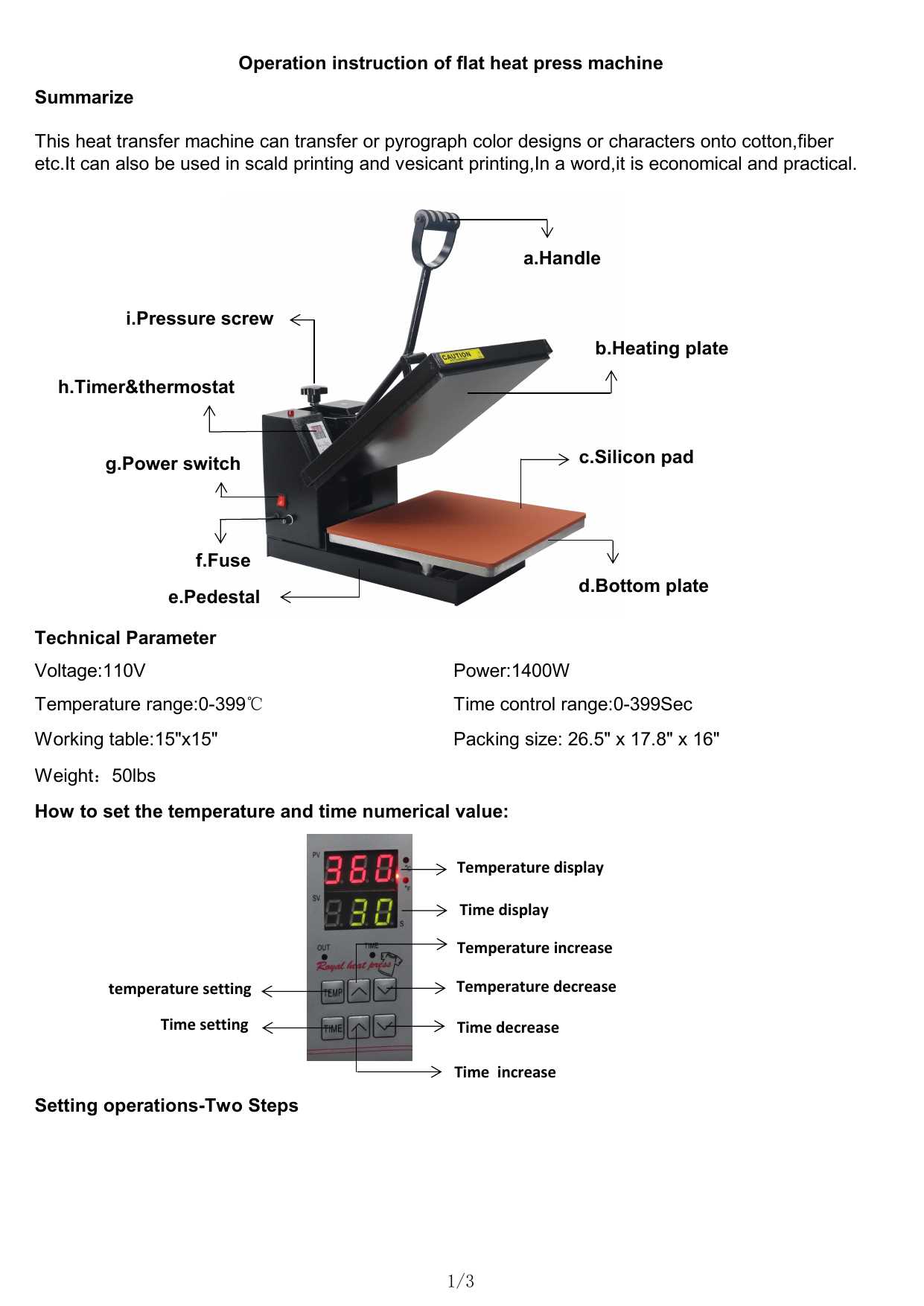

Additionally, understanding the settings is crucial. Temperature, time, and pressure adjustments can significantly impact the quality of your transfers. Experimenting with these parameters will help you find the ideal combination for different materials.

Maintenance is another key aspect to consider. Regular cleaning and inspection of the machine will extend its lifespan and maintain optimal performance. Be sure to follow the manufacturer’s recommendations to keep your device in top shape.

Setting Up the Equipment Properly

Establishing a reliable workspace is essential for achieving optimal results with your apparatus. Proper organization and configuration will enhance efficiency and ensure safety during operations. This section outlines the necessary steps to prepare your setup for seamless functionality.

Begin by selecting a sturdy, flat surface that can withstand the weight and temperature generated by the device. Ensure that the area is well-ventilated to prevent overheating and to maintain air circulation. Verify that there are no flammable materials nearby that could pose a risk during use.

Next, connect the unit to a suitable power source, making sure to follow the electrical specifications provided by the manufacturer. Inspect the power cord for any signs of wear or damage before plugging it in. If using an extension cord, confirm that it is rated for the device’s electrical requirements.

Once powered, calibrate the settings according to the type of materials you plan to work with. Adjust the temperature and duration settings as needed, based on the guidelines provided for your specific tasks. It is advisable to perform a test run with scrap material to ensure everything is functioning correctly before proceeding with your main projects.

Finally, keep all necessary tools and materials within reach to streamline your workflow. By taking these preparatory steps, you will create an effective and safe environment for your projects.

Choosing the Right Materials

Selecting suitable substances is crucial for achieving optimal results in your crafting endeavors. The right choices can significantly impact the final outcome, ensuring durability and aesthetic appeal. Understanding the various options available and their properties will help you make informed decisions tailored to your specific projects.

Types of Materials

There are several types of substances to consider, each offering distinct characteristics that cater to different applications. Below is a table summarizing common materials and their typical uses:

| Material Type | Characteristics | Common Uses |

|---|---|---|

| Cotton | Soft, breathable, and easy to work with | T-shirts, tote bags |

| Polyester | Durable, resistant to shrinking and wrinkles | Sportswear, outdoor gear |

| Blend Fabrics | Combines properties of multiple fibers | Varied applications, versatile |

| Canvas | Heavyweight, strong, and sturdy | Backpacks, home decor |

Considerations for Selection

When choosing substances, consider factors such as the intended application, the desired finish, and the compatibility with your crafting process. Testing different options on small samples can also help determine the best fit for your specific needs, ensuring satisfaction with the final product.

Operating Instructions for Best Results

To achieve optimal performance from your device, it is essential to follow a set of guidelines that ensure efficiency and quality. Proper usage can significantly enhance the outcomes and longevity of your equipment. Understanding the correct procedures will lead to consistent and satisfactory results.

Preparation: Before using your device, ensure it is set up correctly and all components are in place. Proper setup is crucial for effective operation and preventing potential issues.

Temperature and Timing: Adjust the settings according to the material and type of project. Accurate temperature and timing are key factors in achieving the desired results. Make sure to follow recommended settings for different applications.

Application: Apply even pressure across the surface to ensure uniform results. Avoid applying excessive force, which can lead to imperfections and damage to both the material and the equipment.

Maintenance: Regular maintenance is vital for the longevity of your device. Clean it after each use and check for any wear and tear. Proper care will help maintain its performance and extend its service life.

By adhering to these guidelines, you will ensure efficient and high-quality results every time you use your device.

Safety Precautions to Follow

Ensuring a secure environment during the operation of equipment is crucial for both safety and efficiency. Adhering to specific guidelines minimizes risks and promotes a safer working atmosphere.

- Always wear appropriate protective gear, including gloves and safety glasses, to shield against potential hazards.

- Keep the workspace tidy and free of any obstructions to prevent accidents and ensure easy access to equipment.

- Ensure proper ventilation in the area to avoid the buildup of fumes or excessive heat.

- Do not leave equipment unattended while in use, and always supervise during operation.

- Familiarize yourself with emergency procedures and ensure that safety equipment, such as fire extinguishers, is readily available.

By following these precautions, users can significantly reduce the risk of injury and maintain a productive working environment.

Troubleshooting Common Issues

This section addresses frequent challenges that users may encounter while operating their device. Understanding these common obstacles and their solutions can enhance the overall experience and improve efficiency. Below are typical problems and suggestions to resolve them.

Insufficient Temperature

If the machine does not reach the desired temperature, ensure that it is properly calibrated. Check the power source and ensure that it is connected securely. Additionally, verify the settings and adjust them if necessary. If the problem persists, inspect the heating element for any signs of damage.

Uneven Pressure Distribution

When the output is inconsistent, it may be due to uneven pressure applied during operation. Make sure the surface is level and the item is placed correctly. If necessary, adjust the pressure settings to achieve uniformity. For persistent issues, consider consulting the manufacturer for further assistance.

Maintenance Tips for Longevity

To ensure the durability and optimal performance of your equipment, regular care and attention are essential. By following a few straightforward practices, you can significantly extend its lifespan and maintain consistent results.

First, always keep the surface clean and free from any debris or residues. A gentle cleaning solution can be used to wipe down the working area after each use. Additionally, check for any wear and tear, addressing minor issues promptly to prevent them from becoming major problems.

Proper storage is also crucial. When not in use, ensure that the device is stored in a dry, cool place, away from direct sunlight and moisture. Utilizing protective covers can safeguard it from dust and accidental damage.

Finally, periodically inspect electrical components and connections to ensure they are functioning correctly. Routine checks will help identify any potential safety hazards before they escalate. By implementing these simple yet effective maintenance strategies, you can enjoy reliable performance for years to come.