In the realm of modern farming and heavy machinery, the availability of detailed resources is crucial for effective operation and maintenance. These resources provide essential insights into the functioning of various equipment, ensuring that users can maximize their efficiency and performance. Well-crafted guides are invaluable for both seasoned professionals and newcomers, offering step-by-step instructions and critical information tailored to specific models and tasks.

Such documents are designed to facilitate a thorough understanding of machinery, covering everything from initial setup to advanced troubleshooting techniques. They address common challenges and provide clear solutions, helping users to avoid potential pitfalls and extend the lifespan of their equipment. By following these comprehensive resources, operators can ensure that their machinery performs optimally and remains in excellent condition.

Whether for routine maintenance or more complex repairs, having access to these well-organized references is indispensable. They serve as a vital tool in the daily operations of agricultural professionals, enhancing both productivity and safety. Through detailed explanations and practical advice, these resources contribute significantly to the smooth functioning of modern agricultural technology.

Understanding John Deere Instruction Manuals

Comprehending the guidance materials provided by machinery manufacturers is crucial for efficient operation and maintenance. These resources are designed to ensure users can maximize the functionality and longevity of their equipment. They typically include detailed information on setup, operation, and troubleshooting, which can significantly impact the performance of the machinery.

Key Components of the Guidance Materials

These documents usually encompass several essential elements. First, they offer comprehensive operational guidelines that outline how to use the equipment safely and effectively. Additionally, they provide maintenance instructions to help keep the machinery in optimal condition. Troubleshooting sections are also included to assist users in diagnosing and addressing common issues.

How to Navigate and Utilize the Resources

To make the most of these documents, users should familiarize themselves with the structure and layout. Typically, a table of contents at the beginning allows for easy navigation. Indexes or search functions help locate specific topics quickly. Understanding these features will enhance the ability to find pertinent information and apply it correctly.

What Are John Deere Instruction Manuals?

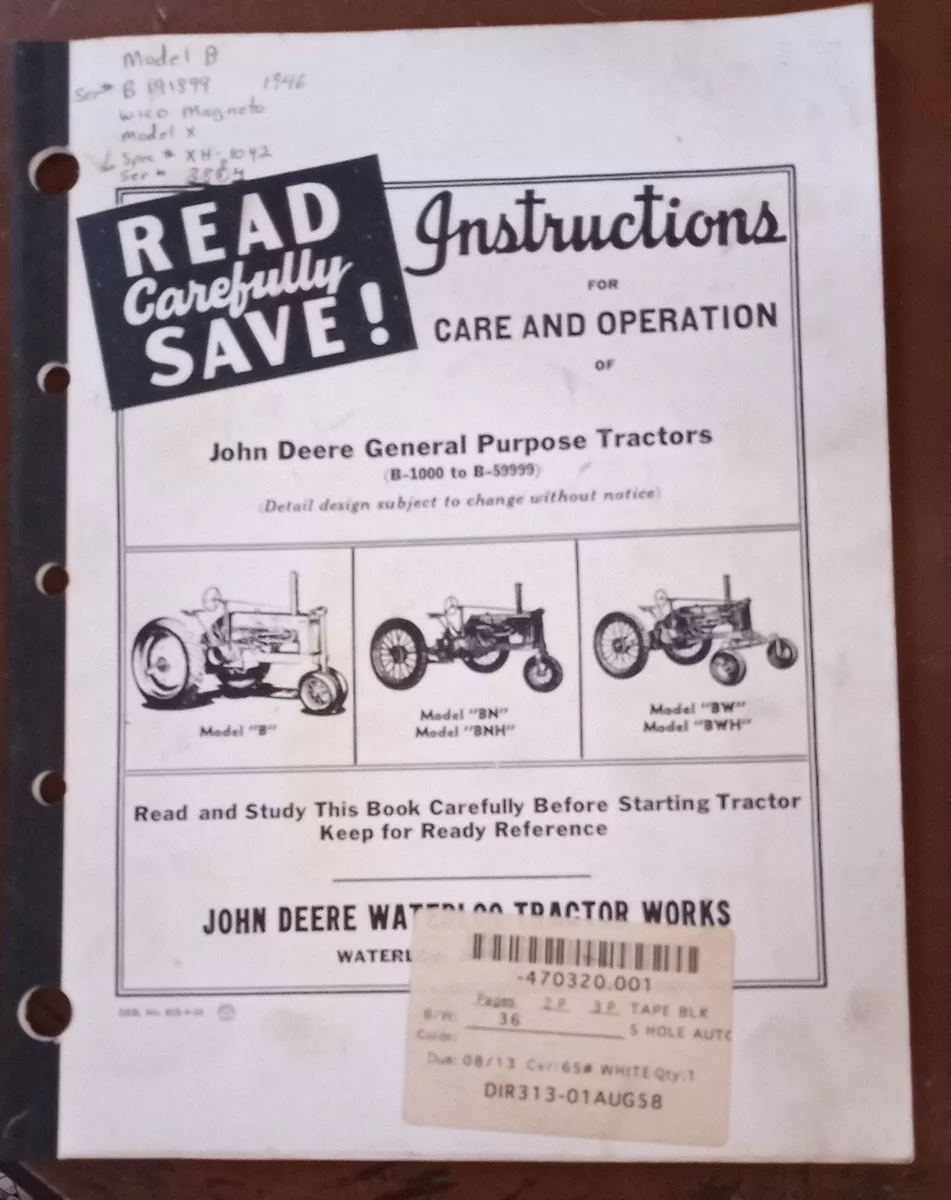

When it comes to operating and maintaining machinery, having a reliable guide is essential. These documents provide users with comprehensive information about the equipment’s features, operation procedures, and maintenance tasks. They are designed to help users understand how to effectively utilize their machinery, ensuring safety and optimal performance.

Typically, these guides include:

- Operational Guidelines: Step-by-step instructions on how to use the equipment efficiently and safely.

- Maintenance Tips: Recommendations for regular upkeep to prolong the lifespan of the machinery.

- Troubleshooting Advice: Solutions for common issues that users may encounter during operation.

- Safety Precautions: Important information to prevent accidents and ensure safe usage.

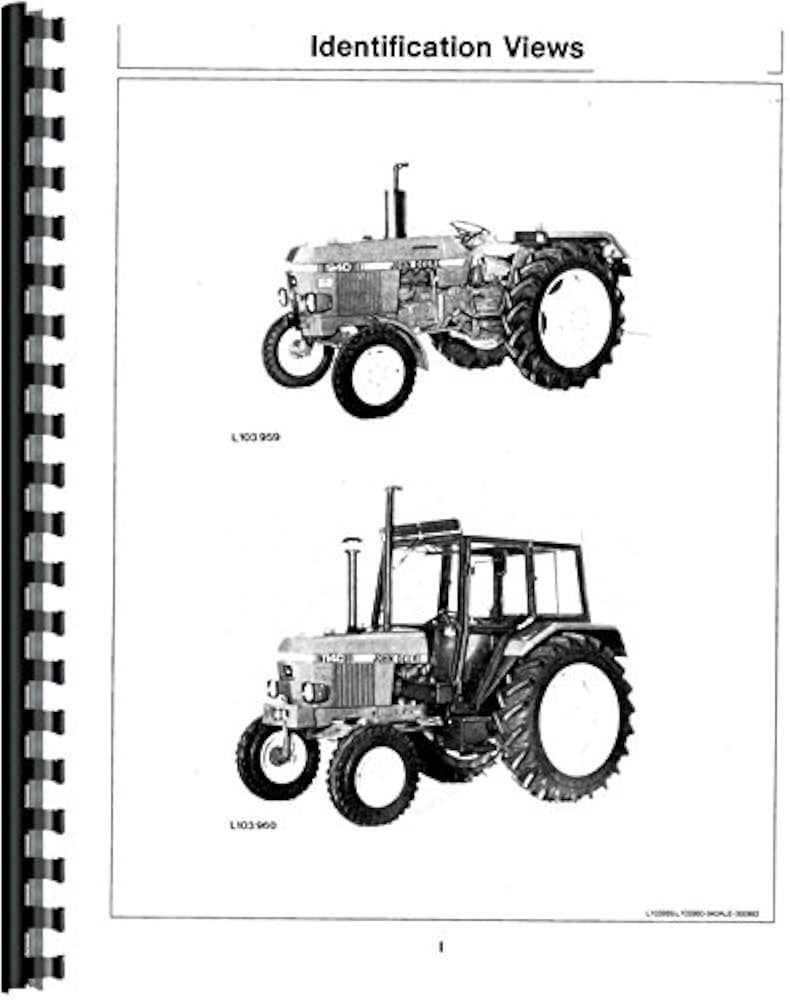

- Parts Diagrams: Visual representations of the machinery’s components for easier identification and repair.

These resources are invaluable for both new and experienced operators, providing clear and detailed instructions to facilitate effective equipment management.

The Importance of Proper Manual Usage

Using a guide effectively is crucial for the efficient operation and maintenance of machinery. These documents provide essential insights and detailed instructions that help users achieve optimal performance and ensure safety. By adhering to the recommendations and procedures outlined, operators can prevent potential issues, extend the lifespan of their equipment, and avoid costly repairs. Proper utilization of these resources not only enhances productivity but also safeguards against mishaps and operational errors.

How to Access and Find Manuals

Obtaining user guides and reference documents for machinery and equipment can greatly enhance your operational efficiency and maintenance routines. These resources provide crucial details on proper use, troubleshooting, and care procedures. Accessing these documents can be done through several effective methods, ensuring you have the right information when you need it.

Here are some practical ways to locate these essential documents:

- Manufacturer’s Website: Visit the official website of the equipment manufacturer. Most companies offer a dedicated section where you can download or view various documents related to their products.

- Customer Support: Reach out to the manufacturer’s customer support team. They can provide you with the necessary documents or guide you on where to find them.

- Online Forums: Explore online communities and forums related to the equipment. Experienced users often share or recommend links to useful documents.

- Retailers and Dealers: Contact authorized dealers or retailers. They frequently have access to product documentation and can assist in obtaining specific guides.

Using these methods will help you efficiently locate the information you need, ensuring optimal use and maintenance of your equipment.

Common Issues and Troubleshooting Tips

Understanding and addressing frequent problems that arise with agricultural machinery can significantly improve performance and longevity. This section provides guidance on identifying and resolving typical issues, ensuring efficient operation and minimizing downtime. Equipped with the right knowledge, users can tackle challenges confidently and maintain optimal functionality.

Engine Problems: If the engine fails to start or runs unevenly, check the fuel level and quality. Ensure that the fuel filters are clean and replace them if necessary. Verify the battery charge and connections, as well as the spark plugs, for proper operation.

Hydraulic System Issues: Common hydraulic problems include reduced power or erratic movement. Inspect hydraulic fluid levels and ensure there are no leaks in the system. Replace the hydraulic fluid and filters as needed, and examine the hydraulic pump and cylinders for wear or damage.

Transmission Difficulties: If shifting gears becomes difficult or the machine experiences slipping, check the transmission fluid level and condition. Look for any signs of contamination or leakage. Ensure that the clutch and linkages are correctly adjusted and functioning.

Electrical System Failures: Electrical issues might manifest as malfunctioning lights or non-responsive controls. Examine fuses and wiring for damage or loose connections. Replace any blown fuses and repair or replace damaged wires as needed.

Preventative Maintenance: Regular upkeep is crucial for preventing these issues. Follow the recommended maintenance schedule, perform routine checks, and address minor problems before they escalate. Consistent care can extend the life of the equipment and ensure reliable performance.

Updating and Replacing Your Manuals

Keeping your operational guides current and relevant is essential for effective maintenance and usage of your equipment. As technology advances and models evolve, ensuring you have the latest versions of these documents can significantly impact performance and safety. This section will explore methods for obtaining updated versions and replacing outdated copies.

Obtaining Updated Versions

To stay current, you need to regularly acquire the most recent editions of your guides. Here are some methods to do so:

- Manufacturer’s Website: Check the official site for the latest publications and updates. Most companies offer downloadable files or online access to recent versions.

- Customer Support: Contact the customer service department for assistance in acquiring the latest documentation. They can provide links or send physical copies if necessary.

- Authorized Dealers: Visit or call authorized dealerships for updated versions. Dealers often have access to the most recent guides and can assist with replacements.

- Online Forums: Participate in forums related to your equipment. Members often share updated resources and can offer guidance on where to find the latest versions.

Replacing Outdated Copies

Replacing old documents is crucial to ensure you’re working with the most accurate information. Consider these approaches:

- Check for Revisions: Verify if your current guide has any revisions or errata that need to be addressed before replacing it.

- Disposal of Old Guides: Safely dispose of outdated copies to avoid confusion. Ensure they are discarded in a way that protects sensitive information.

- Backup Copies: Keep digital backups of your updated guides. This ensures you always have access, even if physical copies are lost or damaged.

- Regular Review: Periodically review your guides and documentation to identify any new updates or necessary replacements.

By staying updated with the latest versions and replacing outdated documents, you ensure optimal performance and safety for your equipment.

Resources for Further Support and Help

When seeking additional assistance for operating or maintaining your equipment, there are numerous resources available to provide expert guidance and troubleshooting advice. These resources encompass a range of platforms designed to address common queries, offer detailed solutions, and ensure optimal performance of your machinery.

Online Support Portals offer comprehensive access to FAQs, troubleshooting tips, and user forums. These platforms are invaluable for finding solutions to common issues and connecting with other users who may have faced similar challenges.

Technical Support Hotlines provide direct access to knowledgeable representatives who can assist with specific concerns or complex problems. They are particularly useful for obtaining personalized help and detailed explanations tailored to your situation.

Authorized Service Centers are equipped with specialized tools and expertise to handle repairs and maintenance. Visiting these centers ensures that any issues are addressed by professionals with a thorough understanding of the equipment.

Workshops and Training Sessions can enhance your understanding of the equipment’s functionality and maintenance requirements. Participating in these sessions allows you to gain practical skills and insights directly from experts.

Utilizing these resources can significantly enhance your ability to effectively manage and troubleshoot your equipment, ensuring smooth and efficient operation.