Cutting tools have become indispensable in both professional and home environments, offering precise and efficient solutions for a variety of tasks. These tools, designed for ease of use and versatility, provide a range of cutting options suitable for different materials and projects. Understanding how to properly utilize these tools can enhance productivity, ensure safety, and deliver the best results for your specific needs.

To achieve optimal performance, it’s essential to familiarize yourself with the various features and capabilities of your cutting device. This includes recognizing the types of blades, understanding the adjustments and settings, and knowing the best practices for different cutting techniques. Whether you’re working with paper, cardboard, or other materials, having a thorough knowledge of your cutting tool’s functionality will help you achieve cleaner, more accurate cuts every time.

In this guide, we will explore the key elements that make these tools effective and user-friendly. You’ll learn step-by-step methods to set up, operate, and maintain your cutting device, ensuring longevity and reliability. By mastering these techniques, you’ll be able to tackle any cutting task with confidence and precision.

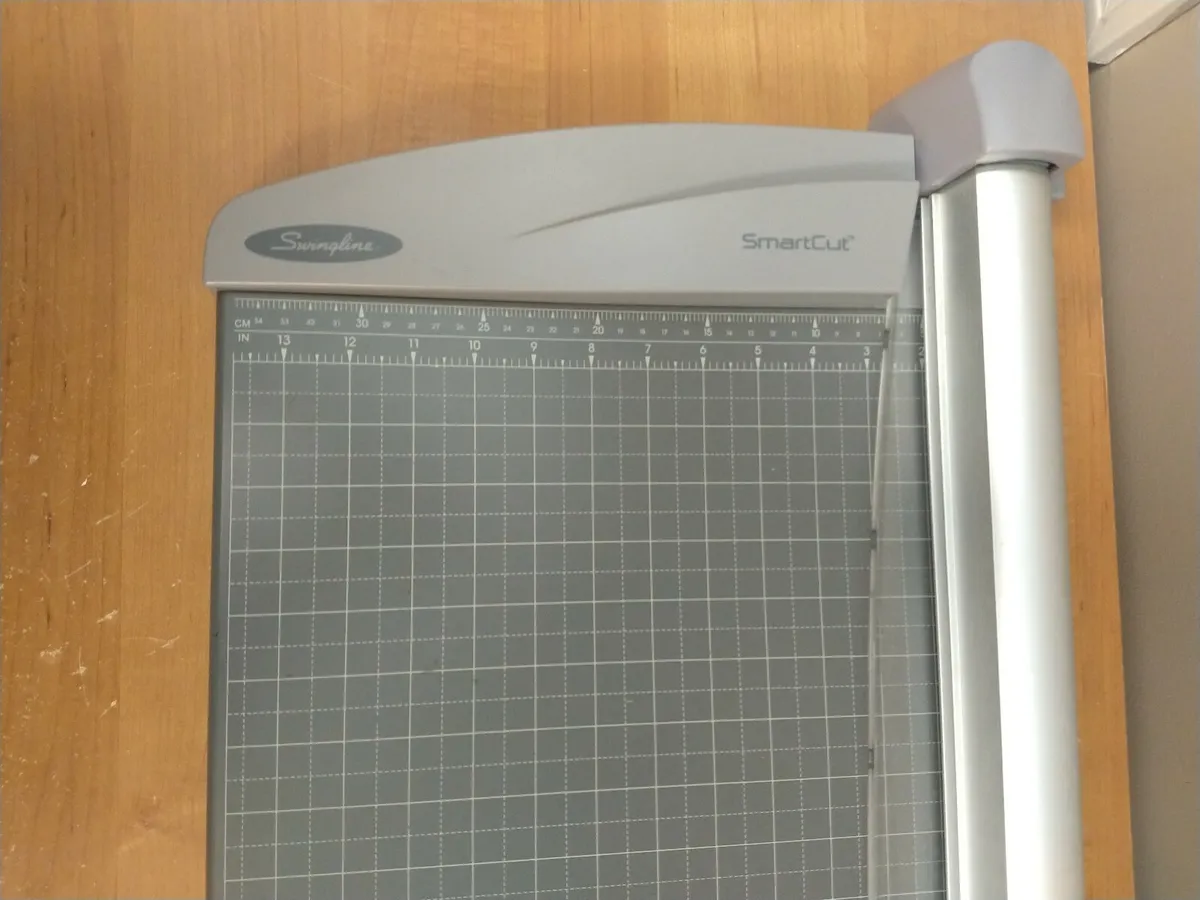

Overview of the Swingline SmartCut Features

The precision trimmer is designed to offer a seamless and efficient cutting experience, combining ease of use with advanced functionalities. This section provides a comprehensive look at the various features that make this tool a reliable choice for both personal and professional use.

Key Functionalities

The trimmer is equipped with a range of capabilities to ensure precise and clean cuts every time. These features are specifically tailored to cater to different materials and cutting needs, providing versatility and control.

- Rotary Blade Mechanism: The tool utilizes a rotary blade that ensures smooth and accurate cutting. This mechanism minimizes the risk of jagged edges and guarantees a clean finish.

- Multiple Cutting Styles: The device supports various cutting styles, including straight, wave, and perforated cuts, allowing users to choose the most suitable option for their projects.

- Durable Cutting Base: A sturdy base made from high-quality materials provides stability, reducing the chances of slipping or uneven cuts.

Enhanced Safety Features

Safety is a priority with this cutting tool. Several features have been integrated to ensure a secure cutting environment, especially when used frequently or by multiple people.

- Safety Lock Mechanism: A safety lock is included to prevent accidental activation of the blade, making it safer to handle, especially in environments where children are present.

- Protective Guard: A built-in protective guard covers the blade when not in use, reducing the risk of injury during storage or transport.

- Non-Slip Rubber Feet: The base is equipped with non-slip rubber feet to keep the tool firmly in place during operation, providing added stability and control.

By understanding these key features, users can maximize the potential of their cutting tool, ensuring it meets all their creative and practical needs.

Step-by-Step Guide to Setup

This guide provides a comprehensive overview to help you get your cutting device ready for use. Following these steps will ensure that your tool is properly configured, calibrated, and ready for accurate cutting tasks. Let’s explore the setup process in detail to ensure optimal performance.

Unpacking and Initial Preparation

- Carefully remove the device from its packaging, ensuring all components are present.

- Place the tool on a stable, flat surface to prevent any movement during setup.

- Inspect the device for any visible damage that might have occurred during shipping.

- Familiarize yourself with the different parts and controls of the tool by referring to the labeled diagrams provided.

Adjusting and Calibrating the Device

- Connect the tool to a power source if required, or ensure that the batteries are correctly installed.

- Set the cutting length by adjusting the guide rails to the desired measurement. Make sure the measurements align correctly to avoid any miscuts.

- Check the sharpness of the cutting blade and replace it if necessary to ensure clean cuts. Follow the manufacturer’s recommendations for blade maintenance.

- Perform a test cut using a scrap piece of material to check alignment and cutting precision. Adjust settings as needed for perfect results.

- Once the device is calibrated and adjustments are made, secure all locks and safety mechanisms to prevent any accidental movements or adjustments.

By following these steps, you ensure your cutting tool is set up correctly and is ready for precise and efficient operation. Always refer back to this guide whenever you need to reconfigure or adjust your settings for different cutting tasks.

How to Use the Cutting Tools Effectively

Achieving clean and precise cuts requires more than just operating the equipment; it involves understanding and applying the right techniques to ensure optimal results. Effective use of cutting devices not only improves the quality of your work but also extends the lifespan of the tools. Below are some key strategies to help you utilize these tools to their fullest potential.

Preparing for the Cutting Task

- Inspect the Tool: Before starting, ensure that the cutting instrument is in good condition. Check for any signs of damage or wear that could affect performance.

- Set Up the Work Area: Clear your workspace of any obstructions. A clean and organized area will enhance safety and precision.

- Select the Right Blade: Choose a blade suitable for the material you are cutting. Different blades are designed for specific tasks and materials.

Executing the Cut

- Measure and Mark: Accurately measure and mark the material before cutting. This will guide your cuts and reduce the chance of errors.

- Align Properly: Ensure that the material is correctly aligned with the cutting guide or blade. Proper alignment is crucial for achieving straight cuts.

- Apply Steady Pressure: Use consistent pressure when making the cut. Avoid forcing the tool, as this can lead to uneven cuts or damage.

By following these guidelines, you can enhance your cutting efficiency and achieve superior results. Regular maintenance and proper usage will ensure that your cutting tools perform well and last longer.

Maintenance Tips for Longevity

To ensure the extended performance and reliability of your cutting device, regular upkeep is essential. Proper maintenance helps prevent malfunctions and extends the lifespan of the equipment. By following a few key practices, you can maintain its efficiency and avoid unnecessary repairs.

Regular Cleaning

Keep the cutting area free from dust and debris by routinely wiping it down. Use a soft, dry cloth to remove any particles that may affect performance. For more thorough cleaning, a gentle cleanser designed for office equipment can be used, but make sure the device is turned off and unplugged before applying any cleaning agents.

Periodic Inspection and Lubrication

Inspect the moving parts periodically to ensure they are functioning smoothly. Look for signs of wear and tear, and if any components seem loose or misaligned, address these issues promptly. Additionally, applying a light lubricant to the hinges and other moving parts can help maintain smooth operation and reduce friction.

Troubleshooting Common Issues with SmartCut

When using a cutting device, you might encounter several issues that can affect its performance. Understanding and addressing these common problems can help ensure smooth operation and maintain the effectiveness of the tool. This section provides guidance on identifying and resolving frequent challenges users face.

Paper Jams

Paper jams are a common issue and can occur due to misalignment or overloading. To resolve this problem, follow these steps:

| Issue | Solution |

|---|---|

| Paper is stuck | Carefully remove the jammed paper by pulling it out slowly. Ensure the device is turned off before attempting to clear the jam. |

| Misaligned paper feed | Adjust the paper guides to match the width of the paper and ensure that the paper is loaded straight. |

| Overloaded paper tray | Remove excess paper and reload the tray according to the recommended capacity. |

Inconsistent Cutting Results

If the cutting results are uneven or inconsistent, consider the following solutions:

| Issue | Solution |

|---|---|

| Dull blade | Check the sharpness of the blade. Replace or sharpen the blade if necessary to ensure clean cuts. |

| Incorrect blade alignment | Verify that the blade is correctly aligned. Adjust it if needed according to the manufacturer’s specifications. |

| Uneven paper thickness | Ensure that the paper being cut is of uniform thickness and that the cutting device is set to handle the paper type effectively. |

Safety Precautions for Optimal Use

Ensuring a safe environment while operating cutting tools is crucial for both user safety and the longevity of the equipment. Proper handling and adherence to safety protocols can prevent accidents and ensure the device performs effectively. Below are key safety measures to consider.

- Read All Instructions: Before using the equipment, thoroughly review all provided guidelines and instructions. Understanding the operation and safety features is essential for safe usage.

- Keep Hands Clear: Always keep hands and fingers away from the cutting area to avoid accidental injuries. Use the designated handles or controls to operate the device.

- Inspect Regularly: Regularly check the equipment for any signs of wear or damage. Ensure all parts are functioning correctly before use to avoid malfunctions.

- Use Correct Materials: Only use materials that are specified for the device. Avoid forcing materials that are too thick or too hard, as this can cause damage or malfunctions.

- Operate on a Stable Surface: Place the equipment on a stable and level surface to prevent tipping or movement during use. Ensure that the area around the equipment is clear of obstacles.

- Unplug When Not in Use: When the equipment is not in use, especially during maintenance or adjustment, disconnect it from the power source to prevent accidental activation.

- Train Properly: Ensure that anyone using the equipment is properly trained and aware of all safety procedures. Supervision and proper instruction are key to safe operation.