In the realm of industrial and residential applications, ensuring the reliable performance of machinery is crucial. Proper use and maintenance of equipment significantly contribute to its longevity and efficiency. To achieve this, access to detailed and well-structured guidelines is essential for both new users and experienced operators.

Understanding the intricacies of your equipment can prevent common issues, minimize downtime, and optimize functionality. These documents provide step-by-step instructions, safety recommendations, and troubleshooting tips, making them invaluable resources. Whether you are setting up new equipment or maintaining existing systems, these resources offer the knowledge needed to keep operations running smoothly.

Technical documents are meticulously crafted to cover every aspect of use, from initial setup to advanced troubleshooting. By following these expert recommendations, users can ensure their equipment operates at peak performance, reducing the risk of errors and extending the lifespan of vital components.

Understanding Goulds Pumps: A Comprehensive Guide

When exploring mechanical devices designed for moving fluids, it’s essential to grasp the fundamental concepts and operational principles that ensure efficient performance. This guide delves into the key aspects of these complex systems, providing insights into their various types, core components, and the nuances of their application across different industries.

Fluid transfer mechanisms are categorized based on their design and intended use. Each category offers unique advantages suited to specific tasks, making it crucial to select the appropriate type for optimal functionality. A detailed understanding of these variations can significantly impact the longevity and reliability of the equipment in various settings.

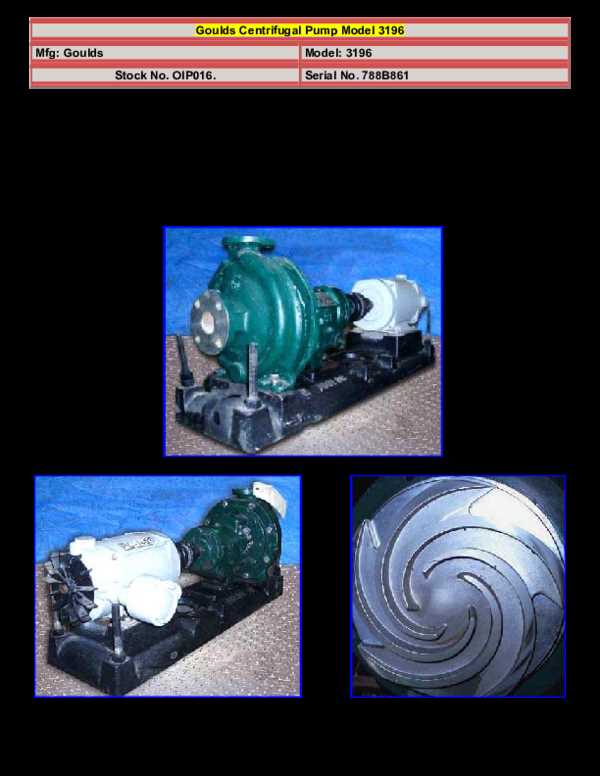

Beyond basic functionality, it’s important to be familiar with the individual parts that make up these systems. From the motor to the impeller, each element plays a critical role in the overall efficiency and durability of the device. Understanding how these components work together can aid in troubleshooting and maintaining the system, ensuring it operates at peak performance.

Moreover, these devices are integral to a wide range of industries, including agriculture, manufacturing, and water treatment. Their application requires not only knowledge of their mechanics but also an understanding of how to adapt their use to specific environmental and operational conditions. This guide aims to equip users with the knowledge needed to make informed decisions about selecting, maintaining, and troubleshooting fluid handling systems.

How to Locate Goulds Pumps Manuals

Finding the right documentation for your equipment is essential for proper maintenance and operation. Whether you’re troubleshooting a technical issue or conducting routine upkeep, having access to the correct guides is crucial. In this section, we’ll explore effective strategies for locating the necessary documents, ensuring you have the information you need at your fingertips.

Search Online Resources

One of the most straightforward ways to find the documentation you need is through online resources. Manufacturer websites often provide a dedicated section for product literature, where you can search by model number or product line. Additionally, various third-party websites may host these documents, offering quick access to a wide range of resources.

Utilize Product Identification

If you’re having trouble locating the right document, make sure you have the correct product information on hand. This typically includes the model number, serial number, or specific part identifiers. Having these details will help narrow down your search and ensure you find the precise documentation required for your equipment.

Step-by-Step Guide to Using Goulds Pump Instructions

Understanding how to operate and maintain your equipment is crucial for ensuring long-term reliability and efficiency. This guide provides a clear and concise roadmap for navigating and applying the guidelines provided with your machinery, helping you make the most of the information available.

Below is a step-by-step breakdown that will assist you in properly interpreting and following the provided documentation:

| Step | Description |

|---|---|

| 1. Initial Review | Begin by thoroughly reviewing the entire document. This will give you an overview of the key points, safety precautions, and operational procedures. |

| 2. Identify Key Sections | Identify sections that are relevant to your specific needs, such as installation, troubleshooting, and regular maintenance. |

| 3. Follow Safety Guidelines | Always prioritize the safety protocols outlined in the document to prevent accidents and ensure safe operation. |

| 4. Installation Process | Carefully follow the setup procedures, ensuring that all components are correctly installed and aligned as described. |

| 5. Regular Maintenance | Refer to the maintenance schedule provided, and perform the necessary tasks at recommended intervals to keep the equipment running smoothly. |

| 6. Troubleshooting | Use the troubleshooting section to diagnose and resolve common issues. This can save time and reduce the need for professional repairs. |

| 7. Documentation and Updates | Keep your document up to date with any new information or updates from the manufacturer, and ensure it’s accessible for future reference. |

By following these steps, you can maximize the performance and longevity of your machinery, ensuring it operates at its best.

Troubleshooting Common Issues with Goulds Pumps

Ensuring the efficient operation of industrial fluid-handling systems requires a proactive approach to addressing operational challenges. Understanding potential issues and their solutions can prevent downtime and extend the longevity of your equipment.

Performance Drops

One of the most common problems in fluid systems is a decrease in efficiency. This can manifest as reduced flow rate, lower pressure, or inconsistent output. To diagnose and fix this, consider the following:

- Clogged Components: Debris or buildup in the impeller or piping can restrict flow. Regular inspection and cleaning are essential.

- Worn Parts: Components such as seals, bearings, or the impeller may wear down over time, leading to inefficiencies. Replacing these parts when signs of wear appear can restore optimal function.

- Improper Calibration: Incorrect settings or adjustments can lead to performance issues. Verify all configurations against the manufacturer’s specifications.

Vibration and Noise

Unusual vibrations or noise can be indicative of underlying mechanical issues. Left unaddressed, these can lead to more serious failures. The primary causes include:

- Misalignment: If the equipment is not properly aligned with the motor, excessive vibration can occur. Checking alignment regularly is crucial.

- Loose Fasteners: Over time, bolts and other fasteners may loosen, causing components to vibrate. Tightening them can often resolve this issue.

- Cavitation: Occurs when air bubbles form in the liquid, leading to noise and potential damage. Ensure that the system is free of air pockets and that suction conditions are optimal.

Addressing these common problems promptly will help maintain the reliability and efficiency of your fluid-handling system, minimizing the risk of costly repairs and downtime.

Interpreting Technical Diagrams in Goulds Manuals

Understanding technical diagrams is crucial for anyone working with complex equipment. These visual representations convey essential information about the system’s layout, components, and connections. By carefully analyzing the diagrams, users can gain insights into the operational flow, identify key parts, and troubleshoot potential issues effectively. The ability to interpret these diagrams accurately ensures that maintenance and repairs are carried out with precision.

Recognizing Key Symbols and Notations

Technical diagrams often use a range of symbols and notations to represent various components and processes. Familiarizing yourself with these symbols is the first step in accurately interpreting the visual data. Common elements might include lines for piping, shapes for valves, and other standardized icons representing electrical or mechanical parts. Each symbol is designed to be intuitive but may require a reference guide to fully understand its application in the system.

Following the Flow of Operations

Diagrams not only illustrate individual parts but also depict the sequence of operations within the system. By tracing the pathways, you can follow the flow from one component to the next, gaining a clear understanding of how each part interacts with others. This holistic view is essential for diagnosing issues, as it allows you to pinpoint where a disruption might occur and what effects it could have on the overall functionality. Mastering this skill enhances your ability to maintain and repair complex machinery efficiently.

Essential Maintenance Tips from Goulds Documentation

Proper upkeep is crucial for ensuring the longevity and optimal performance of your equipment. Following guidance on routine care can significantly enhance reliability and efficiency. This section outlines key practices derived from expert documentation to help you maintain your system effectively.

Regular Inspection and Cleaning

Routine checks are vital for identifying potential issues before they become major problems. Periodically inspect all components for wear and tear or damage. Ensure that all accessible parts are cleaned regularly to prevent the buildup of debris, which can lead to malfunctions or reduced efficiency. Regular maintenance not only extends the life of the equipment but also ensures it operates at peak performance.

Proper Lubrication and Fluid Levels

Maintaining appropriate lubrication and fluid levels is essential for smooth operation. Follow the recommended schedule for applying lubricants to moving parts to reduce friction and wear. Additionally, regularly check and refill fluids as specified in the documentation. Proper levels of lubrication and fluids help prevent overheating and premature component failure, ensuring reliable performance over time.

Where to Find Goulds Pumps Replacement Parts

Locating replacement components for your machinery can be a straightforward task if you know where to look. There are several reliable sources where you can find the parts needed to ensure the optimal performance of your equipment. These sources include authorized dealers, specialized online retailers, and the original manufacturer’s website. Additionally, contacting local distributors or service centers may provide access to the required parts along with professional support for installation and maintenance. Exploring these options can help you quickly obtain the components necessary to keep your system running efficiently.