Imagine a versatile solution designed to simplify the movement of various items. This handy helper is not just a convenience, but a crucial tool for those who need to transport objects with ease, whether in a professional setting or at home. Understanding how to utilize this system effectively will significantly enhance its benefits.

In the following sections, we will explore key features, step-by-step procedures, and tips to maximize the potential of this practical device. By familiarizing yourself with its functionality, you can ensure smooth and efficient usage, making every task less of a burden and more of a streamlined process.

Whether you’re lifting, rolling, or adjusting, this guide will provide you with the essential knowledge to operate your new equipment confidently. Let’s dive into the specifics that will empower you to make the most out of this innovative tool.

Overview of Total Trolley Features

This section provides a comprehensive exploration of the key characteristics that define the utility and versatility of the product. The discussion highlights its adaptability, design elements, and various functional aspects that enhance user experience across different scenarios.

Versatile Design and Configuration

The equipment is engineered with a modular design that allows for multiple configurations, making it suitable for a wide range of tasks. Its structure can be adjusted to meet specific needs, whether for transportation, storage, or as a work platform.

- Convertible setup to accommodate different purposes

- Compact and lightweight design for ease of use

- Adjustable height and dimensions for enhanced functionality

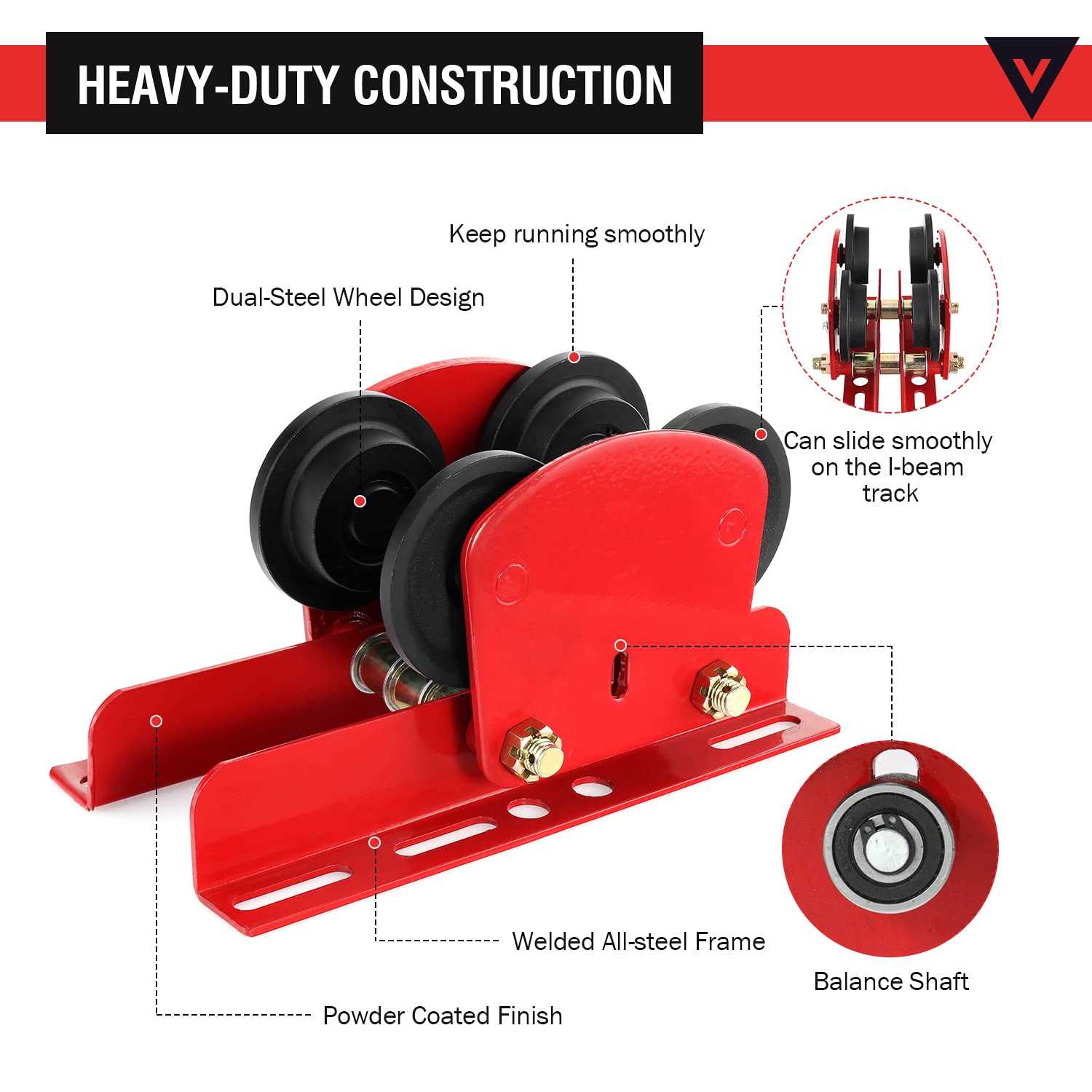

Durability and User-Friendly Features

Constructed with robust materials, the product is built to withstand frequent use in various environments. It offers features designed to improve user convenience, ensuring a smooth and efficient operation.

- Heavy-duty construction for long-lasting performance

- Ergonomic handles for comfortable grip and control

- Easy-to-navigate wheels with locking mechanisms for stability

- Simple folding mechanism for quick storage and transport

Steps to Assemble the Trolley

In this section, we will guide you through the process of putting together your new equipment. Each stage is carefully designed to ensure a smooth and efficient assembly. Follow the instructions step by step, and you will have your unit ready for use in no time.

1. Unpack and Organize Parts

Begin by carefully unpacking all components from the box. Lay them out on a clean, flat surface, and verify that all items listed in the parts list are present. This will make it easier to identify each piece during the assembly process.

2. Attach the Wheels

Start by attaching the wheels to the base frame. Ensure that the wheels are securely fastened using the provided bolts and nuts. Double-check that the wheels spin freely and are properly aligned to avoid any operational issues later.

3. Assemble the Frame

Next, connect the frame pieces together according to the provided diagram. Make sure all connections are tight and secure. This is crucial for maintaining the stability of the entire structure.

4. Install the Handle

Attach the handle to the frame by aligning it with the designated slots. Secure it in place with screws or bolts as indicated. The handle should feel sturdy and comfortable when grasped.

5. Secure the Shelves

Position the shelves within the frame, ensuring they are level and properly aligned. Fasten them securely using the provided hardware. Confirm that the shelves can support the intended weight without any wobbling.

6. Final Adjustments

Once all components are assembled, inspect the entire unit to ensure everything is properly tightened and aligned. Make any necessary adjustments to guarantee that the unit is ready for use.

Following these steps will ensure that your equipment is assembled correctly and is ready for its intended purpose. Taking the time to carefully follow each instruction will result in a reliable and durable product.

Proper Use and Handling

To ensure safe and efficient operation, it is essential to follow best practices for the correct use and management of the equipment. This section outlines key guidelines that will help in maintaining performance and extending the lifespan of the device.

Safe Operation

Always operate the equipment in accordance with its intended purpose. Avoid using the device in conditions that exceed its design specifications, such as overloading or exposure to harsh environments. Regularly inspect the components for wear or damage, and replace any faulty parts immediately to prevent accidents.

Handling and Storage

When handling the equipment, use appropriate lifting techniques to avoid injury. Store the device in a clean, dry location, away from extreme temperatures or corrosive substances. Proper storage not only protects the equipment from damage but also ensures it remains in optimal working condition for future use.

Maintenance and Care Guidelines

Proper upkeep ensures the longevity and optimal performance of your equipment. Consistent attention to various components, coupled with routine checks, can prevent potential issues and extend the overall lifespan of the product. This section outlines essential steps and best practices to maintain functionality and ensure the safety of continued use.

Start by inspecting all moving parts regularly to detect any signs of wear or damage. Pay close attention to the wheels and axles, as they are prone to collecting debris and experiencing friction-related wear. Lubricate these areas periodically with an appropriate lubricant to maintain smooth movement and reduce the risk of deterioration.

Ensure that fasteners, such as bolts and screws, remain tight and secure. Loose hardware can lead to instability and potential hazards. If any components appear loose or damaged, they should be tightened or replaced immediately to avoid compromising safety.

Clean the surfaces with a damp cloth to remove dirt and grime. Avoid using harsh chemicals or abrasive materials, as they may damage the finish or affect the structural integrity. If the product is used in environments exposed to moisture or corrosive substances, consider applying a protective coating to prevent rust and corrosion.

Store the equipment in a dry, sheltered location when not in use. Exposure to extreme weather conditions can lead to premature wear and tear. If storage space is limited, cover the equipment with a protective sheet to shield it from dust and moisture.

By following these guidelines, you can ensure that your equipment remains reliable and safe to use for an extended period. Regular maintenance not only preserves the functionality but also enhances user safety and satisfaction.

Common Issues and Troubleshooting

In any system, occasional problems can arise, and understanding how to address these issues efficiently is crucial for smooth operation. This section provides insights into frequent challenges users might face and offers practical solutions to resolve them effectively.

Problem: System Fails to Operate

If the equipment does not start, first check if it is properly connected to the power source. Ensure that all cables are securely attached and that the power switch is turned on. Additionally, inspect for any visible damage or loose components that might be affecting performance.

Problem: Unusual Noise During Operation

Unusual sounds can indicate mechanical issues or misalignment. Examine the moving parts for any signs of obstruction or wear. Lubricate moving components as recommended, and verify that all parts are correctly aligned and securely fastened.

Problem: Inconsistent Performance

Inconsistent performance may be due to a variety of factors, including uncalibrated settings or faulty components. Review the calibration settings and adjust them as needed. Check for any loose or damaged parts that could be affecting the system’s stability.

Problem: Error Messages or Fault Codes

When encountering error messages or fault codes, refer to the troubleshooting guide for specific codes and their meanings. Follow the suggested steps to address the issue, which may involve resetting the system or replacing faulty parts.

Problem: Difficulty with Controls

If the controls are unresponsive or difficult to use, ensure that there is no obstruction or damage to the control panel. Clean the controls regularly and check for any software updates that might improve functionality.

By identifying and addressing these common problems, users can maintain efficient operation and extend the lifespan of the equipment. Regular maintenance and prompt troubleshooting are key to avoiding prolonged downtime.

Safety Tips for Operating the Trolley

Ensuring safety while using handling equipment is essential for preventing accidents and maintaining a smooth workflow. By adhering to best practices, users can mitigate risks and enhance operational efficiency. The following guidelines are designed to help you navigate potential hazards and use the equipment safely and effectively.

1. Conduct Regular Inspections: Before beginning any operation, always check the equipment for signs of wear or damage. Inspect all moving parts, brakes, and safety features to ensure they are functioning correctly. Report any issues immediately and avoid using faulty equipment.

2. Follow Load Limits: Adhere to the manufacturer’s specified load capacity to prevent overloading. Exceeding the recommended limits can compromise the equipment’s stability and increase the risk of accidents.

3. Maintain a Clean Workspace: Keep the area around the equipment clear of obstacles and debris. A clutter-free environment reduces the chances of tripping or collisions, contributing to a safer working condition.

4. Use Proper Handling Techniques: When moving the equipment, ensure that it is properly balanced and maneuvered smoothly. Avoid sudden movements or sharp turns that could cause instability.

5. Wear Appropriate Personal Protective Equipment (PPE): Always wear the recommended safety gear, including gloves and safety shoes, to protect yourself from potential hazards while operating the equipment.

6. Train Personnel: Ensure that all operators are adequately trained in the correct use of the equipment. Proper training helps in understanding safety procedures and handling techniques, reducing the likelihood of accidents.

7. Follow Manufacturer’s Guidelines: Adhere strictly to the operational instructions provided by the manufacturer. These guidelines are designed to ensure safe and efficient use of the equipment.

8. Avoid Unauthorized Modifications: Do not alter or modify the equipment in any way that could affect its safety or performance. Unauthorized changes can lead to malfunctions or unsafe conditions.

By following these safety tips, you can help ensure that the equipment operates efficiently and safely, minimizing the risk of accidents and maintaining a secure working environment.