Understanding the operation and features of your advanced packaging equipment is crucial for optimal performance and efficiency. This guide provides detailed information on the essential functions, setup, and maintenance of the machine, ensuring you can utilize its full potential. Whether you are a new user or looking to refresh your knowledge, this resource will assist you in navigating through the various functionalities of your equipment.

The document covers a wide range of topics, including assembly instructions, operational procedures, and troubleshooting tips. By following the guidelines and recommendations provided, you will be equipped to handle common issues and ensure the longevity of your machine. Each section is designed to offer clear, actionable insights, helping you make the most out of your investment.

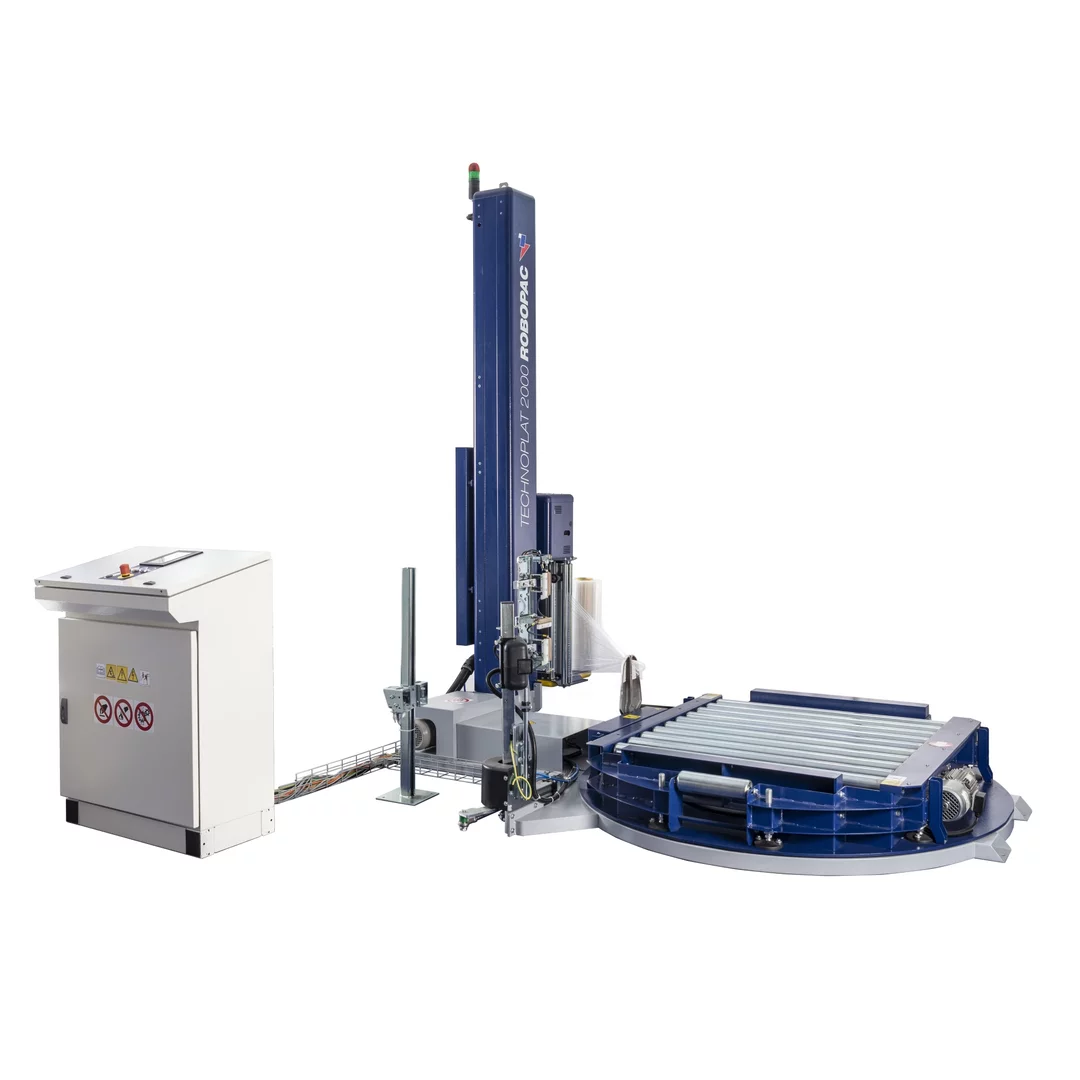

Understanding the Robopac 708 System

To fully grasp how the advanced packaging technology functions, it’s essential to explore the core concepts and components that define its operation. This section will delve into the foundational elements that contribute to the system’s efficiency and effectiveness. By understanding these principles, users can better appreciate the system’s capabilities and optimize its performance for various applications.

Key Components

The system comprises several integral parts, each serving a specific role in the overall process. Familiarizing yourself with these components will provide insight into how they work together to achieve seamless operation.

- Control Unit: Acts as the brain of the system, managing and coordinating the various functions to ensure smooth and accurate performance.

- Sealing Mechanism: Responsible for creating secure seals on packaging materials, essential for maintaining product integrity.

- Feeding System: Handles the automatic feeding of materials into the machine, streamlining the packaging process.

- Conveyor Belt: Facilitates the movement of products through different stages of the packaging line.

Operational Overview

Understanding the operational workflow is crucial for maximizing the system’s potential. Here’s a basic overview of how the system performs its tasks:

- Initialization: The system is powered up and calibrated according to the specific requirements of the packaging task.

- Material Feeding: Packaging materials are fed into the system, guided by the feeding mechanism.

- Product Handling: Products are positioned on the conveyor belt and moved through the various stages of the packaging process.

- Sealing: The sealing mechanism applies the necessary closures or seals to ensure the products are securely packaged.

- Completion: Finished packages are discharged from the system, ready for distribution or further processing.

By gaining a comprehensive understanding of these components and processes, users can effectively operate and troubleshoot the system, ensuring optimal performance and efficiency in their packaging operations.

Overview of Features and Specifications

This section provides a comprehensive summary of the key attributes and technical details associated with the machine. Understanding these elements is crucial for effectively utilizing and maintaining the equipment, as well as for ensuring it meets your specific needs and requirements.

Main Features

- Versatility: Designed to handle a wide range of packaging materials and sizes, making it adaptable to various production environments.

- Ease of Use: Intuitive controls and user-friendly interface streamline the setup and operation processes.

- Efficiency: Equipped with advanced mechanisms to enhance speed and accuracy in packaging tasks.

- Durability: Constructed with high-quality materials to ensure longevity and withstand demanding usage.

Technical Specifications

- Dimensions: The equipment’s dimensions are optimized to fit in diverse workspace configurations.

- Power Requirements: Operates on standard voltage with specific power consumption rates detailed in the technical datasheet.

- Speed: Capable of achieving high packaging speeds, as indicated by the operational performance metrics.

- Weight: The machine’s weight facilitates stability while allowing for easy relocation if needed.

Setup and Installation Guide

Proper configuration and installation are crucial for ensuring that your equipment operates smoothly and efficiently. This section provides a step-by-step approach to setting up your device, allowing you to achieve optimal performance and reliability. By following these instructions carefully, you will be able to complete the installation process with confidence.

1. Unpacking and Inspection

Begin by carefully unpacking all components of the device. Check each item against the list provided to ensure nothing is missing or damaged. It is important to handle all parts with care to avoid any damage before installation.

2. Location Selection

Choose an appropriate location for the device, ensuring it is on a stable surface and away from any obstructions. The area should be well-ventilated and free from excessive dust and moisture to maintain the equipment’s longevity.

3. Assembly Instructions

Follow the assembly instructions included in the package. Secure all components as directed, ensuring each part is correctly fitted and aligned. Use the provided tools and fasteners for a secure assembly.

4. Electrical Connections

Connect the device to a suitable power source, following the voltage and current specifications outlined. Ensure all electrical connections are properly made and that cables are not exposed to any risk of damage.

5. Initial Setup

Once assembled and connected, power on the device and proceed with the initial setup. This may include calibrating settings, running tests, and verifying that all functions operate as expected. Refer to the setup guide for specific procedures required for your device.

6. Safety Checks

Conduct a thorough safety check to ensure that the device is installed correctly and safely. Confirm that all parts are securely in place and that there are no potential hazards present.

By adhering to these guidelines, you will ensure that your equipment is properly installed and ready for use. Regular maintenance and periodic checks will help keep it in optimal condition.

Preparing Your Robopac 708 for Use

Before operating your new packaging machine, it is essential to ensure that it is properly set up and ready for efficient performance. This preparation process involves several key steps to guarantee that the equipment functions optimally and safely. Proper setup not only enhances performance but also prolongs the lifespan of the machine.

Begin by carefully unpacking the unit and checking for any visible signs of damage. Ensure that all components and accessories are present and undamaged. It is advisable to compare the received items with the packing list to confirm completeness.

Next, place the machine on a stable and level surface to avoid any operational issues. Proper placement is crucial for maintaining balance and preventing vibrations during use. Make sure that the area around the machine is clean and free from obstructions.

Connect the machine to a suitable power source, ensuring that the voltage and current specifications match those required by the equipment. Refer to the electrical requirements provided in the documentation to avoid any risk of damage or malfunction.

Lastly, conduct a thorough inspection to ensure that all parts are assembled correctly and that there are no loose connections. Adjust any settings as needed and perform a test run to familiarize yourself with the machine’s operation and verify that it is functioning correctly.

Operating Instructions for Efficiency

Maximizing performance involves a thorough understanding of operational procedures and settings. By following precise guidelines and optimizing parameters, you can enhance the functionality of your equipment and achieve superior results. This section provides essential tips and techniques for operating your machinery efficiently, ensuring that every task is performed with the highest level of productivity and accuracy.

To begin, ensure that all components are properly configured according to the specifications outlined. Regular maintenance and timely adjustments are crucial to avoid unnecessary downtime and maintain peak performance. Familiarize yourself with the control panel and settings, as well as the various operational modes available. Proper calibration and correct usage of these features can significantly impact the overall efficiency of the system.

Additionally, it is important to monitor performance regularly and make any necessary changes based on real-time feedback. Efficient operation is not just about following instructions, but also about continuously assessing and improving the processes to meet evolving needs and conditions. Adopting a proactive approach to managing your equipment will contribute to sustained high performance and reliability.

How to Maximize Performance

Achieving optimal efficiency with your packaging equipment involves understanding and implementing several key strategies. By following best practices and making use of available features, you can ensure that your machine operates at its highest potential, leading to improved productivity and reduced downtime.

Regular Maintenance and Calibration

To keep your equipment running smoothly, adhere to a rigorous maintenance schedule. Regular upkeep not only prolongs the lifespan of the machine but also enhances its performance. Consider these steps:

- Perform routine inspections to identify and address any wear or damage.

- Follow the recommended lubrication procedures to keep moving parts functioning correctly.

- Check and calibrate the machine settings periodically to ensure accurate operation.

- Replace worn components promptly to prevent disruptions in performance.

Proper Training and Operation

Ensure that all operators are thoroughly trained on the equipment’s features and best practices. Well-trained personnel can make a significant difference in the efficiency of the operation. Focus on the following:

- Provide comprehensive training on machine setup, operation, and troubleshooting.

- Encourage adherence to operational guidelines to minimize errors.

- Regularly update training materials to reflect any changes or advancements in technology.

By investing time in maintenance and operator training, you will maximize the efficiency and effectiveness of your packaging processes, leading to better overall results and fewer interruptions.

Maintenance and Care Recommendations

Proper upkeep and regular care are crucial for ensuring optimal performance and longevity of your equipment. By adhering to a consistent maintenance routine, you can prevent unexpected breakdowns and enhance the efficiency of your device.

Regular Inspections: Perform frequent checks to identify any signs of wear or malfunction. This includes examining moving parts, electrical components, and safety features. Address any issues promptly to avoid further complications.

Cleaning: Keep the machinery clean and free from debris. Use appropriate cleaning agents and tools to avoid damaging sensitive components. Regular cleaning prevents buildup that could affect performance.

Lubrication: Ensure that all moving parts are adequately lubricated. Proper lubrication reduces friction and wear, extending the life of mechanical components. Follow the manufacturer’s recommendations for lubrication intervals and types of lubricants.

Component Replacement: Replace worn or damaged parts with genuine components. Using unauthorized or incompatible parts can compromise the machine’s functionality and safety.

Professional Servicing: Schedule periodic professional inspections and servicing. Experienced technicians can perform thorough checks and maintenance tasks that might be beyond routine care.

Following these guidelines will help maintain the efficiency and durability of your equipment, minimizing downtime and extending its useful life.

Keeping Your Device in Top Shape

Maintaining optimal performance of your equipment requires regular care and attention. By following a few essential practices, you can ensure your device remains reliable and efficient over time. Proper upkeep not only extends the lifespan of the equipment but also enhances its overall functionality and performance.

Routine Maintenance

To keep your equipment functioning smoothly, establish a routine maintenance schedule. This includes regular cleaning to remove dust and debris, which can interfere with performance. Checking and tightening any loose components also helps prevent potential issues before they escalate. Adhering to recommended service intervals ensures that any wear and tear is addressed promptly.

Handling and Storage

Proper handling and storage are crucial for preserving the condition of your device. Always handle it with care, avoiding any abrupt movements or impacts that could cause damage. When not in use, store the equipment in a dry, dust-free environment. Using protective covers can also safeguard against accidental damage and environmental factors.