Accurate calibration is essential for any precision measurement system. This document provides an in-depth look at the operational guidelines and best practices necessary for effective utilization of advanced weighing and measurement devices. Proper adherence to these guidelines ensures reliable results and enhances the efficiency of equipment in various settings.

Within this guide, users will find detailed steps and procedures to operate, maintain, and troubleshoot these advanced measurement systems. By following these instructions, individuals can ensure optimal performance and longevity of their equipment. This resource is designed to assist users in mastering the complexities of modern measurement technologies, leading to more accurate and consistent results.

The content here is structured to offer clear and practical advice for users at all levels of expertise. It includes valuable insights and tips for troubleshooting common issues, thereby facilitating smooth and effective use of the equipment. Engaging with this guide will help users to harness the full potential of their measurement systems and achieve their operational goals efficiently.

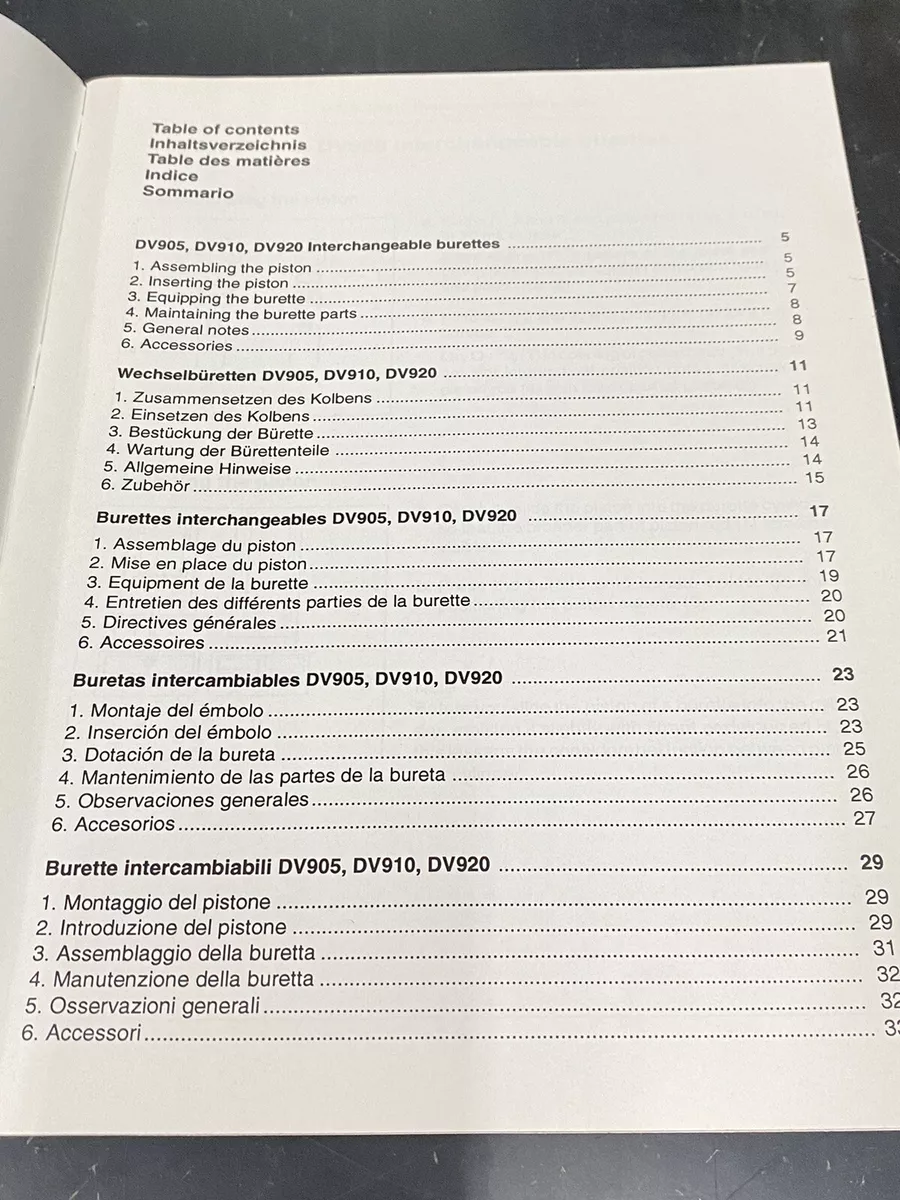

Overview of Mettler Toledo’s Documentation

This section provides a comprehensive look into the guidebooks offered by a leading manufacturer of precision measurement equipment. The available documentation plays a crucial role in ensuring users can effectively operate and maintain their devices. It includes detailed information and procedural instructions designed to assist users in getting the most out of their equipment.

Contents typically cover essential aspects such as setup, calibration, and troubleshooting. Each document is crafted to support users in navigating the various features and functionalities of the equipment, ensuring accurate performance and reliability.

Additionally, the documentation often provides valuable insights into best practices for usage and maintenance, contributing to the longevity and optimal performance of the instruments. Users are encouraged to refer to these guides for a thorough understanding of their equipment and to address any operational challenges they might encounter.

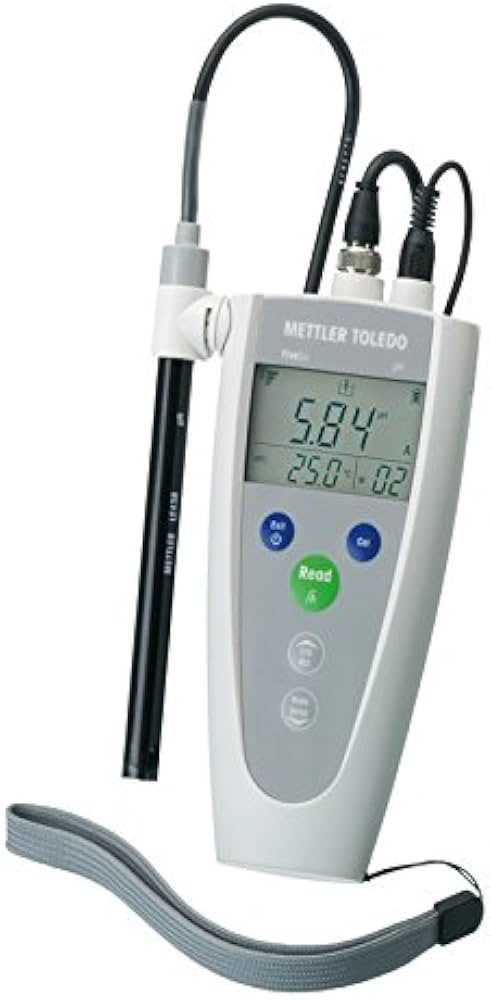

Key Features of Mettler Toledo Devices

Devices from this manufacturer are renowned for their precision and advanced functionality. These instruments offer a range of features that cater to various analytical and measurement needs, ensuring accuracy and reliability in diverse applications.

Precision and Accuracy

- High-resolution measurements for detailed analysis.

- Advanced calibration techniques to ensure consistency.

- Built-in diagnostics to maintain accuracy over time.

User-Friendly Interface

- Intuitive touchscreens for easy navigation.

- Customizable settings to match specific requirements.

- Comprehensive data management features for efficient workflow.

Understanding Installation Procedures

Proper installation is crucial for ensuring the correct functionality and longevity of your equipment. This section outlines the essential steps and considerations for setting up your device effectively. By adhering to these guidelines, you can avoid common issues and ensure optimal performance.

Begin by thoroughly reviewing the provided guidelines to familiarize yourself with the requirements and recommendations. Preparation is key–ensure that you have all necessary tools and components before starting the installation process. It’s important to follow the specified sequence of steps to avoid potential complications.

During installation, precision and attention to detail are vital. Verify that all connections are secure and that the setup aligns with the provided specifications. Regularly check for any signs of improper installation to address issues promptly.

Calibration and Maintenance Guidelines

Effective calibration and routine upkeep are essential for ensuring accurate performance and longevity of measurement equipment. Proper handling and adherence to recommended procedures not only enhance measurement precision but also extend the operational lifespan of the device. Regular attention to these aspects minimizes errors and optimizes functionality.

Calibration Procedures

For accurate measurements, it is crucial to perform calibration according to the manufacturer’s recommendations. Begin by verifying that the equipment is set up on a stable, level surface. Use certified calibration standards that match the measurement range of the equipment. Follow the step-by-step calibration process as outlined in the equipment’s documentation, ensuring each step is meticulously executed.

Maintenance Practices

Routine maintenance involves checking and cleaning the equipment regularly to prevent dust and residue accumulation. Inspect critical components for wear and tear, and replace any damaged parts promptly. Regular software updates and system checks are also recommended to maintain optimal performance and address potential issues before they become problematic.

Adhering to these guidelines will help maintain the reliability and accuracy of the measurement equipment over time.

Safety Protocols and Precautions

Ensuring the safety and proper handling of equipment is crucial for maintaining a secure and efficient working environment. This section outlines essential guidelines and preventive measures that should be observed to avoid potential hazards and ensure the longevity of the apparatus. Adhering to these protocols helps in mitigating risks associated with equipment use and contributes to a safer operational environment.

Proper Training and Familiarization: Before operating any equipment, it is imperative that users receive adequate training. Familiarizing oneself with the operational procedures and safety features of the device minimizes the risk of accidents and ensures that users can handle unexpected situations effectively.

Regular Maintenance and Inspections: Conducting routine checks and maintenance is essential for preventing malfunctions and extending the lifespan of the equipment. Regular inspections help in identifying potential issues before they escalate into serious problems, ensuring the equipment functions correctly and safely.

Personal Protective Equipment (PPE): Utilizing appropriate personal protective gear, such as gloves and safety glasses, is vital when operating or handling the equipment. PPE serves as a barrier against potential injuries and exposure to hazardous materials, enhancing the safety of the user.

Emergency Procedures: In the event of an emergency, it is important to have clear and accessible emergency procedures. Knowing how to respond quickly and effectively to accidents or malfunctions can prevent further damage and ensure the safety of all personnel involved.

Troubleshooting Common Issues

Addressing frequent problems can streamline the resolution process and ensure efficient operation. This section aims to provide guidance on identifying and fixing typical malfunctions that users might encounter.

- Power Supply Problems:

Ensure the device is properly connected to a functioning power source. Check for loose or damaged cables and verify that the power switch is in the “on” position. If the issue persists, inspect the power supply unit for any visible defects.

- Calibration Errors:

Calibration issues can often be resolved by performing a reset or recalibration procedure. Follow the manufacturer’s recommended calibration steps carefully. If errors continue, ensure that all calibration weights and equipment are accurate and in good condition.

- Display Issues:

If the display is not showing information correctly, check for any loose connections between the display and the main unit. Inspect the screen for damage or discoloration. If necessary, consult the troubleshooting section of the device’s guide for specific display-related solutions.

- Software Glitches:

Software problems can often be addressed by restarting the device or updating to the latest firmware version. Ensure that all software settings are correctly configured and perform a factory reset if the issue persists.

- Connectivity Issues:

For problems related to connectivity, verify that all network cables are securely connected and that the network settings are correctly configured. Test the connection with other devices to rule out network issues.

Customer Support and Resources

Providing exceptional support and comprehensive resources is crucial for ensuring users have a seamless experience with their equipment. Access to effective assistance and detailed materials can greatly enhance the functionality and longevity of the products. This section outlines various avenues for support and resources available to users seeking help or additional information.

Support Services

- Customer Service: Reach out to our dedicated support team for assistance with any issues or questions regarding your equipment. They are available through various channels, including phone, email, and live chat.

- Technical Assistance: For more technical inquiries, specialized support is available to address complex problems and provide expert guidance.

- On-Site Support: If necessary, on-site service can be arranged for hands-on assistance and repairs by qualified technicians.

Resource Materials

- Online Knowledge Base: Access a comprehensive database of articles, FAQs, and troubleshooting guides to find answers and solutions.

- Video Tutorials: Watch instructional videos covering various topics, from setup and calibration to advanced features and maintenance tips.

- User Guides: Obtain detailed documentation that provides step-by-step instructions and useful information for operating and maintaining your equipment.