In today’s world of efficient organization, mastering the use of advanced labeling devices can significantly enhance both personal and professional environments. These tools are designed to streamline the process of creating clear, durable labels for various applications. Whether you’re aiming to organize office supplies, manage inventory, or add a touch of professionalism to your documents, understanding the functionalities and features of these devices is essential.

With a focus on optimizing labeling practices, this guide delves into the essential techniques and tips for utilizing these handy gadgets effectively. It covers everything from setting up the device to creating and printing labels, ensuring you achieve precise and reliable results every time. By familiarizing yourself with the key aspects of operation and maintenance, you’ll be equipped to make the most out of your labeling tool.

Embrace the full potential of your labeling tool with our detailed overview. Discover practical advice and insights that will help you harness its capabilities to keep your workspace or projects impeccably organized and professionally presented.

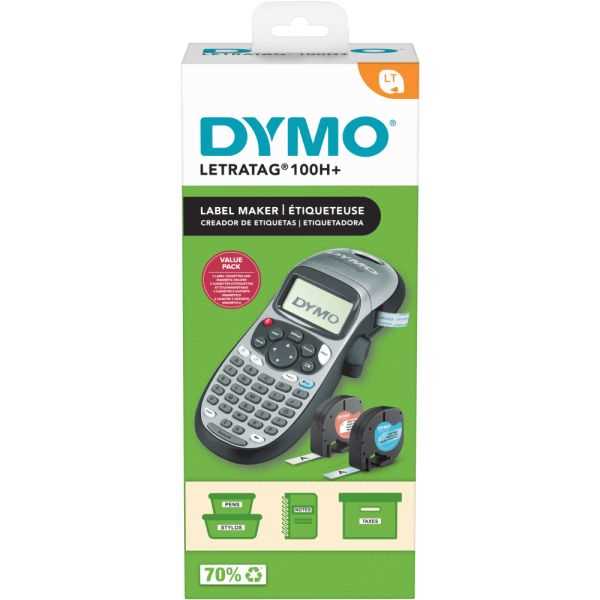

Getting Started with Dymo LetraTag

Embarking on a journey with your new label maker can be both exciting and practical. This section is designed to help you familiarize yourself with the basics of setting up and using your device efficiently. Whether you’re organizing your workspace or labeling your personal items, understanding the core functions will ensure you get the most out of your tool.

Unboxing and Setting Up

Begin by carefully removing the label maker and accessories from the packaging. Ensure you have the batteries installed properly, or connect the device to a power source if it supports direct connection. Insert a label tape cartridge into the designated slot, making sure it is positioned correctly for smooth operation.

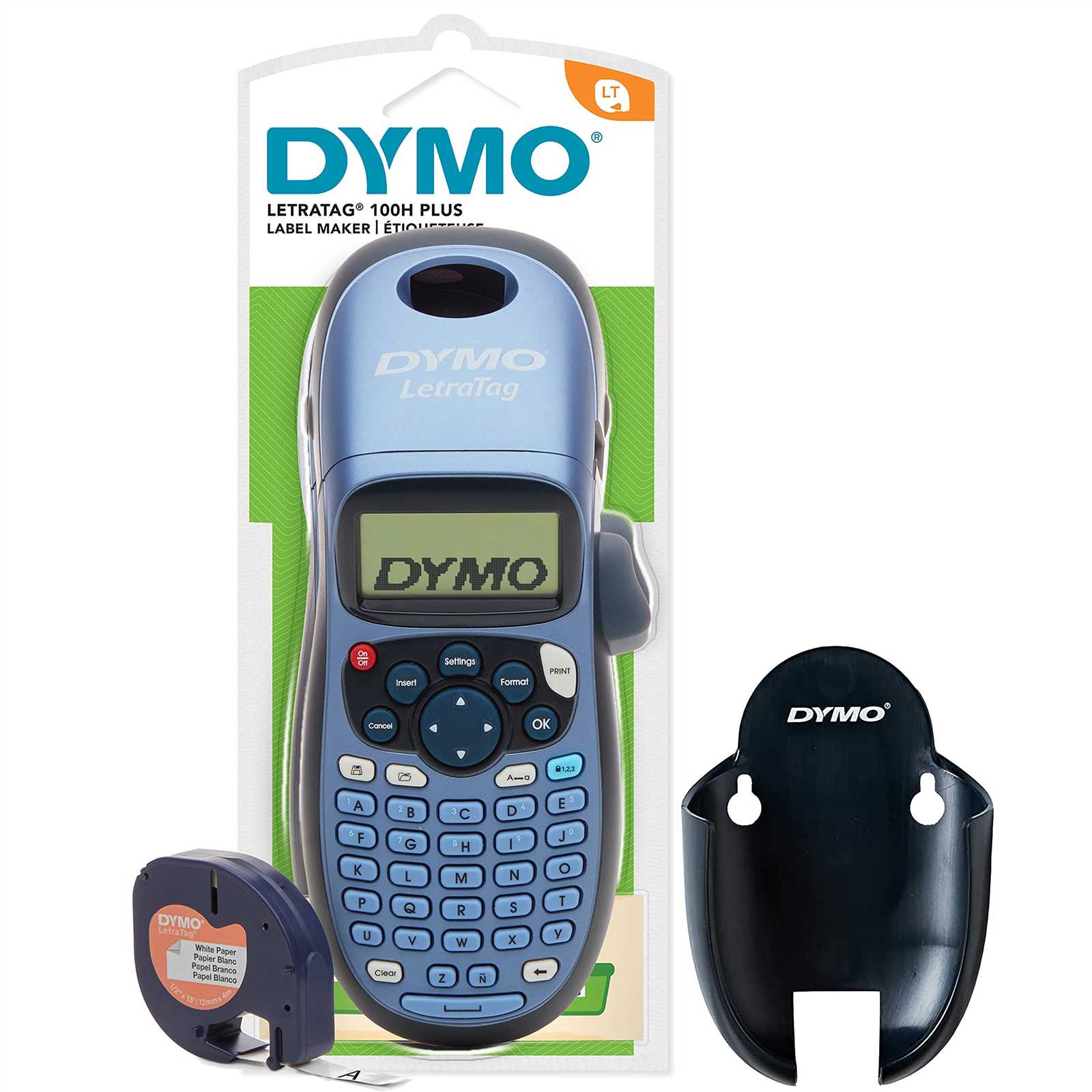

Basic Operation

To start creating labels, power on the device and select your desired settings. You can usually choose from various font styles, sizes, and formats. Input your text using the built-in keyboard, then preview your label to ensure accuracy. Finally, print the label and trim as needed to complete your task. Regular maintenance and proper handling will keep your label maker in optimal condition.

Setting Up Your Dymo LetraTag Device

Getting your label maker ready for use involves a few straightforward steps. Proper initialization ensures that your device operates smoothly and delivers accurate results. Follow these guidelines to get your tool set up correctly and start creating labels with ease.

- First, locate the battery compartment on the back of the device.

- Open the compartment and insert the batteries, making sure they are oriented correctly according to the markings inside.

- Close the battery compartment securely, ensuring it is properly latched.

Once the batteries are installed, proceed with the following steps:

- Install the label tape by opening the tape compartment. Place the roll of tape into the compartment, making sure it is seated correctly.

- Thread the end of the tape through the slot in the device as indicated by the arrows or guides inside the compartment.

- Close the tape compartment, ensuring it snaps into place and the tape is properly aligned.

Finally, power on your device and test it to ensure everything is functioning correctly. You are now ready to start creating your labels!

Essential Features and Functions

Understanding the core attributes and capabilities of your labeling device can greatly enhance its effectiveness and efficiency. This section delves into the pivotal features and operations that make your labeling tool a valuable asset. Each function is designed to streamline tasks and optimize user experience, ensuring that labeling becomes a seamless part of your workflow.

| Feature | Description |

|---|---|

| Compact Design | Portable and easy to handle, ideal for quick labeling tasks and storage in tight spaces. |

| Customizable Labels | Ability to create labels with various fonts, styles, and sizes, accommodating different labeling needs. |

| Battery Operation | Powered by batteries for convenience and mobility, allowing use in different locations without the need for an electrical outlet. |

| Easy-to-Use Interface | Simple navigation and straightforward controls for efficient label creation and customization. |

| Variety of Label Tapes | Supports different types of tapes, including plastic, metallic, and fabric, enhancing versatility. |

Creating and Customizing Labels

Designing and personalizing labels is a straightforward yet versatile process that allows you to tailor your labels to meet specific needs. This task involves selecting various settings and options to produce labels that are both functional and visually appealing. From choosing the right text to adjusting the formatting, every step plays a role in achieving the perfect label.

Here are the main steps to consider when crafting and customizing your labels:

- Select the Label Size: Determine the appropriate size for your label based on where it will be used and the amount of text or graphics it will contain.

- Choose a Font: Pick a font that is readable and suits the purpose of your label. Consider style and size to ensure clarity and impact.

- Adjust Text Alignment: Align your text for optimal presentation. Options typically include left, center, or right alignment.

- Add Symbols or Graphics: Enhance your label by incorporating symbols or graphics if needed. This can help convey additional information or make the label more attractive.

- Set Text Formatting: Apply bold, italics, or underline effects to emphasize key parts of your text. Adjusting text size and color can also help improve visibility and appeal.

By following these steps, you can create labels that are not only functional but also tailored to your specific preferences and requirements. Customizing labels effectively ensures they fulfill their intended purpose while also reflecting your personal or organizational style.

Maintaining and Troubleshooting Your Label Maker

Ensuring your labeling device remains in optimal working condition involves regular upkeep and addressing common issues that may arise. Proper maintenance not only prolongs the lifespan of the equipment but also ensures reliable performance for all your labeling needs. In this section, we’ll explore essential practices for maintaining your device and offer solutions to frequent problems encountered by users.

Routine Care Tips

To keep your labeling device functioning smoothly, consider the following routine maintenance tips:

| Task | Description | Frequency |

|---|---|---|

| Clean the Printer Head | Gently wipe the printer head with a soft, dry cloth to remove any dust or debris that could affect print quality. | Every 2-4 weeks |

| Check Battery Level | Ensure the batteries are not depleted. Replace them if necessary to avoid interruptions in your labeling tasks. | Monthly |

| Inspect Labels and Tape | Verify that the label tape is properly installed and not jammed. Replace or reload the tape if needed. | As needed |

Common Issues and Solutions

Here are some typical issues you might encounter and how to address them:

| Issue | Solution |

|---|---|

| Device Does Not Power On | Check if the batteries are installed correctly or replace them with new ones. Ensure the battery contacts are clean. |

| Poor Print Quality | Clean the printer head as described above. If the problem persists, replace the label tape. |

| Label Tape Jam | Open the tape compartment and carefully remove any jammed tape. Reinstall the tape correctly and ensure it feeds through properly. |

Additional Tips and Best Practices

When working with label makers, optimizing your usage can greatly enhance efficiency and output quality. Implementing some thoughtful strategies can help you get the most from your device, ensuring labels are both clear and durable. Here are a few suggestions to consider:

Choosing the Right Labels

- Ensure compatibility: Always select labels that are designed for your specific label maker model.

- Consider label material: Choose between plastic, paper, or fabric depending on the environment and use case.

- Evaluate size options: Pick label dimensions that best fit your needs, whether for small items or larger surfaces.

Efficient Labeling Techniques

- Plan your labels: Draft a clear layout and content before printing to avoid errors and wastage.

- Use high contrast: Opt for text and background colors that provide good visibility and readability.

- Check alignment: Ensure text is properly aligned on the label to enhance its appearance and functionality.

- Store labels properly: Keep unused labels in a dry, cool place to maintain their adhesive quality and prevent damage.

By following these tips, you can streamline your labeling process and achieve professional results every time. Remember, small adjustments can make a significant difference in the effectiveness of your labeling efforts.