Embarking on the journey of creating garments can be both thrilling and challenging. Whether you’re a novice or an experienced tailor, understanding the nuances of your tool is essential to achieving professional results. This section aims to provide a comprehensive overview, ensuring that you can navigate the process with confidence and ease.

Delving deeper, we’ll explore the fundamental components and functionalities that will become your allies in crafting exquisite pieces. By familiarizing yourself with the key elements and techniques, you’ll unlock the full potential of your creative projects.

As we continue, practical advice and tips will be shared to help you troubleshoot common issues and enhance your skills. With this knowledge at your fingertips, you’ll be well on your way to mastering the craft and bringing your textile visions to life.

Getting Started with Your Sewing Machine

Embarking on your journey with a fabric-crafting tool is an exciting endeavor that opens up a world of creativity. Before diving into projects, it’s essential to understand the basics, ensuring a smooth and enjoyable experience.

Unpacking and Setting Up

Begin by carefully removing the components from the packaging, laying them out in an organized manner. Take a moment to familiarize yourself with each part, understanding its purpose and how it contributes to the overall functionality. Position the device on a stable surface, ensuring that it’s level and ready for use.

Understanding the Core Features

Take time to explore the primary features, which are crucial for your crafting activities. Identify the controls and their functions, ensuring you know how to adjust settings to suit your project needs. Learning these fundamentals will empower you to create with confidence and precision.

Setting Up the Machine

Getting started with your new tool involves a few simple steps that will ensure everything runs smoothly. Proper preparation is key to achieving the best results in your projects. Follow these steps carefully to make sure everything is arranged correctly and ready for use.

Begin by locating a stable surface where your equipment can be placed securely. It is important to ensure that the surface is level and free from obstructions. Next, carefully position the device, ensuring it is balanced and won’t shift during operation. Once placed, check that all components are in their proper positions, and nothing is missing.

After positioning, you will need to attach the necessary accessories. These additional parts are essential for the proper functioning of your equipment and should be installed according to the provided guidelines. Make sure each component is securely fastened and correctly aligned.

Finally, connect your device to a power source, and ensure that all connections are tight and secure. Before you begin, it’s important to conduct a brief test to confirm that everything is functioning as expected. Once satisfied with the setup, you can move on to more detailed steps in using your tool effectively.

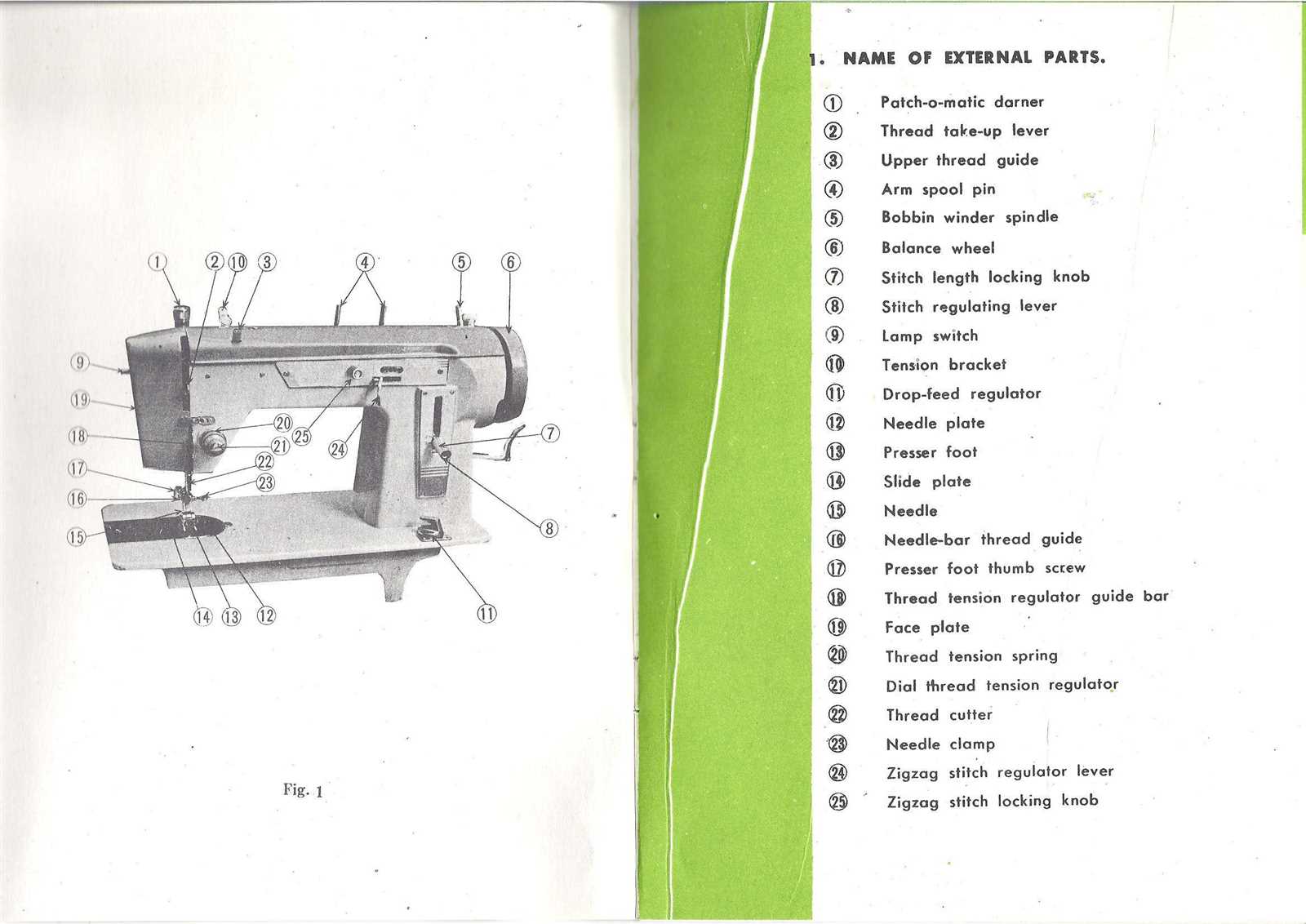

Understanding the Basic Features

Exploring the fundamental aspects of this device reveals how each component contributes to overall functionality. This section delves into key characteristics that users must familiarize themselves with, ensuring smooth operation and optimal performance.

Core Components Overview

The device consists of several essential elements that work together to deliver precise results. These include mechanisms that control motion, adjust tension, and manage various operational settings. Understanding how these parts interact is crucial for achieving desired outcomes efficiently.

Adjustable Settings

One of the significant advantages of this apparatus is its flexibility. It offers a range of customizable settings that allow users to tailor operations to their specific needs. Mastery of these adjustable features enhances the ability to produce consistent, high-quality work.

Threading the Needle and Bobbin

Properly setting up the thread and bobbin is essential for smooth operation and high-quality results. This process involves ensuring that both the upper thread and the lower thread are correctly positioned to work in harmony, allowing the fabric to be stitched efficiently. Following these steps carefully will help avoid common issues such as thread jams and uneven stitches.

To begin, make sure the thread is wound correctly on the spool and that the bobbin is filled and inserted properly. The next step involves threading the needle and guiding the thread through the necessary guides and tension settings. The bobbin needs to be placed in its designated area, ensuring it is secure and aligned with the thread path. Here’s a step-by-step guide to facilitate this process:

| Step | Action |

|---|---|

| 1 | Prepare the spool by placing it on the spool pin. |

| 2 | Wind the thread around the thread guides as instructed. |

| 3 | Insert the bobbin into its case and ensure it is properly threaded. |

| 4 | Thread the needle through the eye from front to back. |

| 5 | Pull the thread under the presser foot and test the stitch. |

Following these instructions will help ensure that both threads are positioned correctly, allowing for a smooth and efficient stitching process. Regular checks and adjustments as needed will help maintain optimal performance and prevent issues during use.

Mastering Stitch Selection and Adjustments

Choosing and fine-tuning stitch patterns is essential for achieving the desired results in your sewing projects. Understanding how different types of stitches and their adjustments affect the outcome will enable you to handle various fabrics and techniques with confidence. This section will guide you through the process of selecting the right stitch and making necessary modifications to enhance your work.

Understanding Stitch Types

Different tasks require specific stitches to achieve the best results. Each stitch type has unique characteristics that cater to various sewing needs, from basic seams to decorative patterns. By familiarizing yourself with the available options, you can select the most suitable stitch for your project, ensuring both functionality and aesthetics.

Adjusting Stitch Settings

Fine-tuning stitch settings is crucial for adapting to different fabrics and achieving precise results. Adjusting parameters such as length and width can significantly impact the stitch’s performance and appearance. Experimenting with these settings allows you to tailor the stitch to your specific needs and improve the overall quality of your sewing endeavors.

Maintaining and Cleaning Your Machine

Proper upkeep of your equipment ensures its longevity and optimal performance. Regular attention to cleanliness and maintenance prevents common issues and enhances the functionality of your device. This section covers essential practices to keep your apparatus in top shape, ensuring smooth operation and minimizing downtime.

Essential Maintenance Steps

Routine care involves several key tasks. Regularly check and clean various components to avoid buildup of dust and debris. Properly lubricate moving parts to ensure smooth operation. Inspect and replace any worn or damaged parts as needed. Adhering to these practices helps maintain efficiency and extends the lifespan of your equipment.

Cleaning Procedures

Cleaning involves both exterior and interior components. Gently wipe the exterior surfaces with a damp cloth. For the internal parts, carefully remove any lint or debris using a soft brush or compressed air. Ensure all parts are dry before reassembling to avoid potential damage from moisture.

| Component | Cleaning Method | Frequency |

|---|---|---|

| Exterior | Wipe with a damp cloth | Weekly |

| Interior (under cover) | Brush or compressed air | Monthly |

| Moving parts | Apply lubricating oil | Every 3 months |

Troubleshooting Common Issues

Addressing challenges with your textile crafting device can often be straightforward with a few troubleshooting steps. Understanding the frequent problems that arise and knowing how to resolve them can greatly enhance your sewing experience.

Inconsistent Stitching: If the stitching on your fabric is uneven or skips, check if the thread is properly threaded through the needle and bobbin. Ensure that the tension settings are adjusted according to the fabric type and thread weight.

Thread Breakage: When the thread frequently snaps, verify that the thread is of good quality and properly installed. Additionally, inspect the needle for damage and replace it if necessary. Sometimes, incorrect threading can also cause this issue.

Fabric Jamming: If your fabric becomes stuck or the machine struggles to feed it through, check for any lint or debris in the feed dogs and around the needle area. Also, make sure you are using the appropriate needle and presser foot for your fabric type.

No Power: If the device does not power on, ensure that it is plugged in securely and that the power switch is turned on. Test the power cord and outlet for proper function as well.

By methodically addressing these common issues, you can maintain smooth operation and extend the life of your textile crafting equipment.