When it comes to optimizing your workshop setup, understanding how to properly use and maintain your equipment is crucial. This guide aims to provide a thorough overview of your tool stand, ensuring that you get the most out of its features and capabilities. Whether you’re a seasoned professional or an enthusiastic DIYer, having a well-rounded grasp of your equipment’s operation can significantly enhance your productivity and safety.

In the following sections, we will delve into various aspects of setup, operation, and maintenance. You will find detailed information on assembling your tool stand, tips for efficient usage, and troubleshooting advice to address any issues that may arise. Our goal is to equip you with the knowledge needed to handle your equipment confidently and effectively.

By familiarizing yourself with the nuances of your tool stand, you can ensure smooth and reliable performance for all your projects. This guide is designed to be a valuable resource, offering clear instructions and practical insights to support your work and help you achieve the best results.

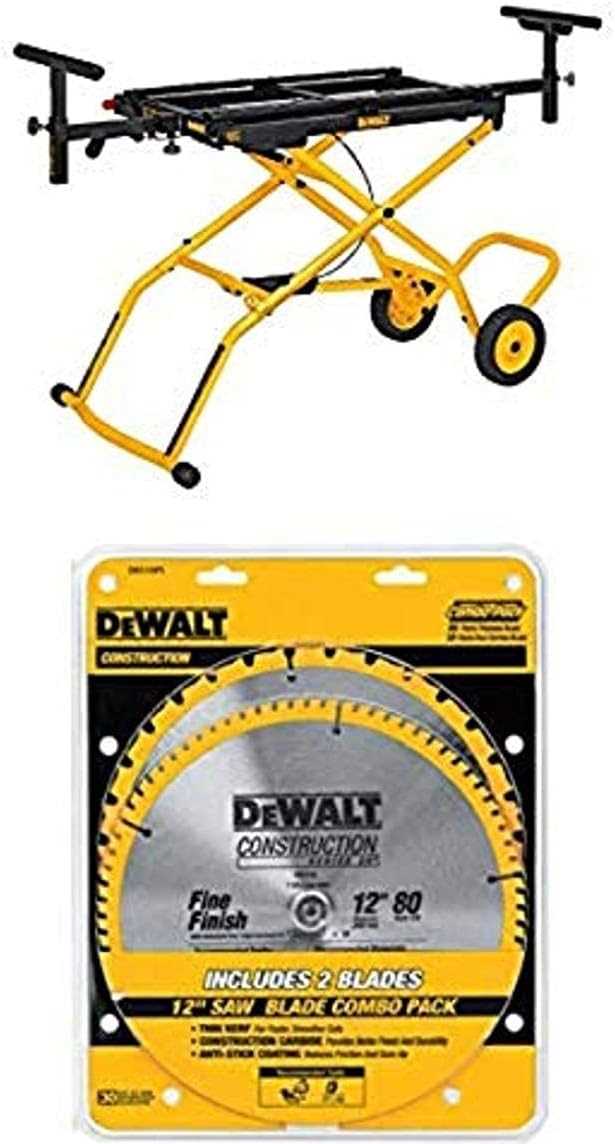

Understanding the Dewalt DWX726

Grasping the essentials of this tool involves delving into its fundamental features and functionality. This equipment is designed to streamline and enhance the efficiency of your work processes, offering a range of capabilities tailored to meet various professional needs. By familiarizing yourself with its specifications, you’ll gain insight into how it can be optimally utilized to achieve precise and effective results.

Key aspects to consider include its structural integrity, adjustability, and ease of use. The robust construction ensures durability, while adjustable components allow for customization based on specific tasks. Moreover, understanding how to operate the tool efficiently can significantly impact productivity and the quality of outcomes.

To fully benefit from this equipment, it’s crucial to explore its operational principles and maintenance requirements. This knowledge will enable you to maximize its potential and ensure longevity, making it a valuable asset in your toolkit.

Setup and Assembly Guidelines

Proper setup and assembly of your equipment are crucial for ensuring optimal performance and safety. This section provides a step-by-step guide to help you efficiently assemble and prepare your tool for use. Following these instructions will help avoid common pitfalls and enhance the longevity of your equipment.

Begin by laying out all the components and hardware on a clean, flat surface. Verify that all parts are present as listed in the provided parts list. Use the tools and fasteners specified in the instructions for assembly. It is essential to follow the sequence of assembly steps carefully to avoid potential issues during operation.

| Step | Description | Tools Required |

|---|---|---|

| 1 | Attach the base to the main support frame using the provided bolts. | Wrench, Screwdriver |

| 2 | Secure the height adjustment mechanism to the base. | Allen Wrench |

| 3 | Install the arms and ensure they are firmly locked into place. | Hex Key Set |

| 4 | Attach the tool to the arms, making sure all connections are tight. | Socket Set |

| 5 | Check all connections and adjust settings as needed. | Level, Calibration Tools |

After assembly, inspect the equipment to ensure it is stable and properly configured. Perform a test run to verify that all parts are functioning correctly and that the tool is ready for use. Regular maintenance and inspection will help maintain optimal performance and safety standards.

Features and Specifications Overview

This section delves into the various attributes and technical details of the equipment, highlighting its capabilities and design. The focus is on providing a comprehensive understanding of the functional aspects and performance characteristics that define this tool. By examining these elements, users can gain insight into how the product meets specific needs and how its features contribute to overall efficiency and effectiveness.

Key attributes include its robust construction, designed to handle demanding tasks with ease, and a range of adjustable settings for customized operation. The tool is engineered for durability, with high-quality materials ensuring longevity even under heavy use. Additionally, the specifications outline its operational parameters, including power output, dimensions, and weight, offering a clear picture of its suitability for various applications.

Furthermore, the equipment boasts user-friendly features such as easy assembly and maintenance, making it accessible for both professionals and DIY enthusiasts. The integration of safety mechanisms and ergonomic design elements ensures comfort and protection during use. This overview provides a detailed look at how these aspects come together to enhance performance and user experience.

Safety Tips for Using the Stand

Ensuring safety while operating equipment is crucial for preventing accidents and injuries. Proper use of the support stand can significantly enhance safety and efficiency. Adhering to the following guidelines will help maintain a safe working environment.

- Read the User Guidelines: Always familiarize yourself with the user instructions provided with the stand. Understanding the recommended procedures and safety warnings is essential.

- Inspect Before Use: Before every use, examine the stand for any signs of damage or wear. Check for loose bolts, cracks, or other issues that might compromise stability.

- Ensure Proper Setup: Set up the stand on a flat, stable surface. Make sure it is fully extended and locked in place before placing any equipment on it.

- Load Capacity: Never exceed the maximum load capacity specified for the stand. Overloading can lead to tipping or collapsing, posing serious risks.

- Keep Work Area Clean: Maintain a clean work area to prevent tripping hazards or obstructions that could interfere with the stand’s stability.

- Use Safety Gear: Wear appropriate personal protective equipment (PPE) such as gloves and safety glasses when working with the stand to protect against potential hazards.

- Secure Equipment: Ensure that any equipment or materials placed on the stand are securely fastened to prevent accidental falls or shifts.

- Supervise Use: When working with the stand, especially in a team setting, ensure that all users are aware of and adhere to safety practices.

- Store Properly: When not in use, store the stand in a dry, safe place to prevent damage and ensure its longevity.

Maintenance and Care Instructions

Regular upkeep is essential for ensuring the optimal performance and longevity of your equipment. Proper care not only helps maintain functionality but also prevents potential issues that might arise from wear and tear. Following a consistent maintenance routine will ensure that your tool remains in top condition for extended periods.

Routine Checks

- Inspect all components for signs of wear or damage before each use.

- Ensure that all fasteners and bolts are tightened securely.

- Verify that all moving parts operate smoothly and without obstruction.

Cleaning Guidelines

- Wipe down surfaces with a clean, dry cloth to remove dust and debris.

- Avoid using harsh chemicals or solvents that could damage the finish.

- Clean air vents and filters regularly to prevent overheating and maintain efficiency.

Following these guidelines will help extend the life of your equipment and ensure reliable operation. Regular attention to maintenance tasks will minimize the risk of unexpected failures and keep your tool functioning at its best.

Common Issues and Troubleshooting

Addressing frequent challenges and resolving issues is essential for maintaining the efficiency of your equipment. This section offers guidance on how to identify and correct common problems that may arise during operation. By understanding these typical difficulties, you can ensure smooth performance and extend the lifespan of your tool.

If the equipment fails to start, check the power source and ensure all connections are secure. Inspect the power cord for any visible damage and replace it if necessary. For issues related to inconsistent performance, verify that all components are properly assembled and that there are no obstructions affecting movement.

In cases where the tool produces unusual noises, examine the moving parts for signs of wear or damage. Lubricate any moving parts as recommended in the guidelines to reduce friction. Additionally, ensure that the tool is not overloaded beyond its capacity, as this can lead to operational problems.

If you experience overheating, allow the tool to cool down before continuing use. Ensure that the ventilation areas are clear of debris and that the tool is not being used inappropriately for extended periods. Regular maintenance, such as cleaning and checking for loose screws, can also help prevent overheating.

For issues related to precision or accuracy, double-check the calibration and alignment settings. Make sure that all settings are adjusted according to the specifications provided and that the tool is used on a stable, level surface to ensure accurate results.

Where to Find Replacement Parts

When you need to replace components for your equipment, knowing where to look can save you time and effort. Various resources are available to help you find the exact parts required to keep your tools in top condition. Whether you’re seeking official suppliers or third-party vendors, it’s important to choose reliable sources to ensure you receive high-quality replacements.

Authorized dealers are often the best place to start. They typically stock genuine parts and can provide expert advice on compatibility and installation. Contacting the manufacturer directly can also be effective, as they may offer a dedicated support line for spare parts and accessories.

Online marketplaces provide a wide range of options. Websites specializing in tool parts can be particularly useful, as they categorize parts by model and type, making it easier to find what you need. Always verify the credibility of the seller and check customer reviews before making a purchase.

Additionally, local hardware stores and repair shops sometimes carry replacement parts or can order them for you. It’s beneficial to visit these stores if you need parts quickly or if you prefer to see the items before buying.

In summary, whether you choose authorized dealers, online platforms, or local shops, ensuring the quality and compatibility of the replacement parts is crucial for maintaining the efficiency and longevity of your equipment.