The modern world of crafting and textile creation has evolved significantly, offering enthusiasts and professionals a range of sophisticated tools to bring their visions to life. Whether you are a seasoned expert or just beginning your journey, understanding the essential features and functions of your sewing equipment is crucial for achieving the best results.

This section delves into the key aspects of operating advanced stitching machines, providing detailed insights into their capabilities. By mastering these devices, users can enhance their creativity, ensure high-quality finishes, and tackle intricate designs with confidence. Explore how to maximize the potential of your sewing equipment and elevate your crafting experience.

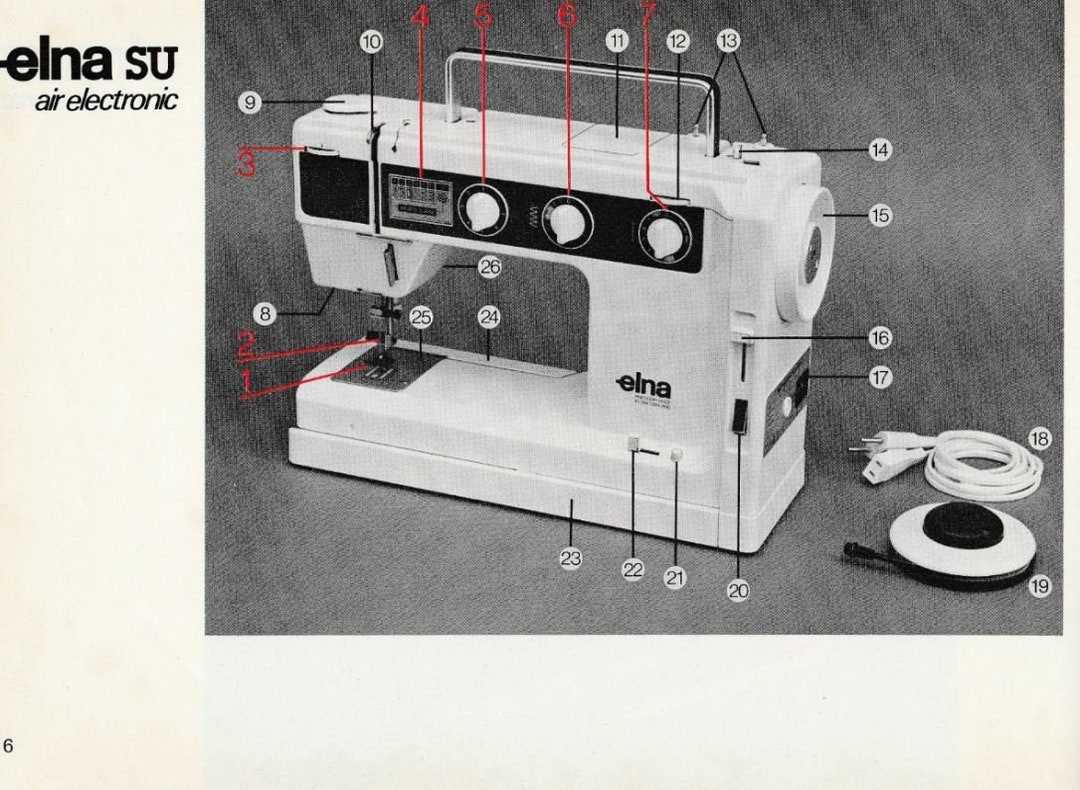

Understanding the Elna Air Artist

Exploring this versatile crafting tool requires grasping its key functionalities and the various tasks it can perform. By comprehending the essential aspects of its operation, users can enhance their creative processes and achieve more refined results.

- First, familiarize yourself with the core features that distinguish this device from traditional crafting tools.

- Secondly, learn how to effectively utilize its customizable settings to cater to different project needs.

- Finally, discover the best practices for maintaining the tool to ensure long-lasting performance and reliability.

Key Features and Functions Explained

Understanding the essential capabilities and operational elements of this advanced sewing machine is crucial for maximizing its potential. This section delves into the primary attributes and how they enhance the overall user experience, ensuring precision, efficiency, and ease of use.

The device is equipped with multiple automatic settings, allowing for seamless adjustments that cater to a variety of fabric types and stitching techniques. Additionally, the inclusion of intuitive controls simplifies the customization process, enabling users to tailor their projects with minimal effort.

One of the standout aspects is the machine’s ability to perform complex tasks with remarkable accuracy. This feature is particularly beneficial for intricate designs, providing consistent results that meet professional standards. Moreover, the machine’s versatility is highlighted by its ability to switch between various modes, each optimized for specific functions, thus broadening the range of creative possibilities.

Another notable characteristic is the user-friendly interface, which offers clear guidance throughout the operation. This ensures that even those new to sewing can confidently explore the machine’s full capabilities, leading to a more enjoyable and productive crafting experience.

Getting Started: A Beginner’s Guide

Embarking on your creative journey can be both exciting and overwhelming. This guide is designed to help you smoothly navigate the initial steps, ensuring a solid foundation for your projects. Whether you’re a complete novice or someone looking to refresh your skills, the following tips and advice will provide you with the essential knowledge needed to begin.

Understanding Your Equipment is crucial for achieving the desired results. Familiarize yourself with the basic components and how they interact. Knowing what each part does and how to properly set it up will save you time and frustration in the long run.

Practice and Patience are key to mastering any new tool. Take the time to experiment with different settings and techniques. Don’t be discouraged by early challenges; with consistent effort, your skills will improve.

As you become more comfortable, start with simple projects to build confidence. Gradually, you can explore more complex ideas, but remember to enjoy the process of learning and creating.

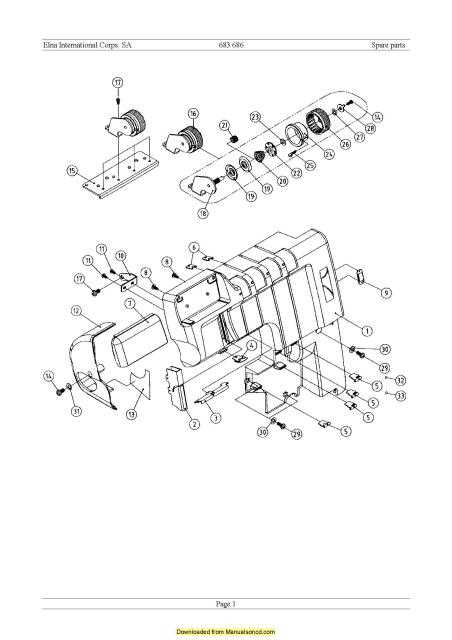

Maintenance Tips for Longevity

To ensure your equipment remains in top condition for years to come, it’s essential to follow a few basic upkeep practices. Regular attention and care can significantly extend the life of your tool, preventing common issues that arise from neglect or improper handling. Below are key strategies that will help maintain your device’s performance and reliability.

Regular Cleaning

Consistent cleaning is crucial to maintaining the functionality of your machine. Dust and debris can accumulate over time, affecting its efficiency. Use a soft, lint-free cloth to gently wipe down the surface after each use. For hard-to-reach areas, consider using compressed air to remove particles without causing damage. Avoid harsh chemicals that could deteriorate the materials over time.

Proper Storage

Storing your device correctly is another important aspect of upkeep. Keep it in a dry, cool environment, away from direct sunlight and moisture. If possible, use a protective cover to shield it from dust when not in use. Additionally, make sure all attachments and accessories are securely stored to prevent loss or damage.

Troubleshooting Common Issues

When working with complex devices, occasional problems may arise that disrupt the workflow. Understanding how to identify and resolve these issues can save time and prevent further complications. Below are some common challenges and effective solutions to ensure smooth operation.

Machine Not Starting

- Power Connection: Ensure the device is properly plugged in and the outlet is functioning.

- Button Response: Check if the power button is fully engaged, and verify if the indicator lights are on.

- Circuit Protection: Inspect the fuse or circuit breaker in the device to ensure it hasn’t tripped or blown.

Thread Tension Issues

- Thread Path: Confirm that the thread is correctly threaded through all guides and tension discs.

- Tension Settings: Adjust the tension dial gradually, testing on scrap material until the desired result is achieved.

- Needle Condition: Examine the needle for any bends or damage that might affect thread handling.

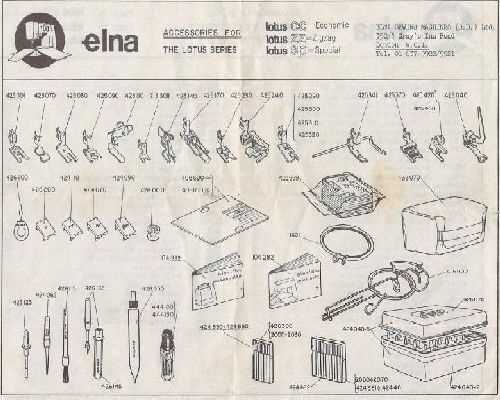

Advanced Techniques for Experienced Users

For those well-versed in their craft, exploring advanced methods can greatly enhance the outcome of their projects. This section delves into specialized techniques that offer precision and creativity, building upon fundamental knowledge. By mastering these practices, users can achieve exceptional results that stand out in both functionality and design.

Precision Stitching Techniques

Refining stitch precision involves adjusting tension settings and employing specialized foot attachments. Mastery of these adjustments allows for seamless sewing on varied materials, ensuring each stitch is both accurate and consistent. Additionally, experimenting with different stitch patterns can add a unique touch to complex projects.

Innovative Fabric Handling

Advanced fabric handling techniques include the use of specialized presser feet and guides to manage challenging textiles. Techniques such as fabric stabilizing and tension balancing contribute to flawless seams and prevent fabric distortion. Understanding how to manipulate different fabrics effectively is key to achieving professional-level results.

Safety Precautions and Best Practices

Ensuring a secure and efficient working environment is crucial for operating any equipment safely. Following proper protocols and adopting best practices helps to prevent accidents and extends the lifespan of the device. This section highlights essential safety guidelines and effective methods to enhance operational efficiency.

| Precaution | Description |

|---|---|

| Read the Guidelines | Before using the device, thoroughly review the provided guidelines to understand its features and limitations. |

| Maintain Cleanliness | Keep the working area and the equipment clean to prevent any obstructions or malfunctions. |

| Use Proper Settings | Adjust the settings according to the requirements of the task to ensure optimal performance and safety. |

| Regular Maintenance | Perform regular maintenance checks to identify and address potential issues before they become significant problems. |

| Proper Storage | Store the device in a secure location to avoid damage and ensure it remains in good working condition. |