When dealing with complex medical equipment, ensuring proper use is key to achieving effective treatment outcomes. This guide offers comprehensive details to help healthcare professionals utilize the device correctly. Through precise application, patients receive the intended dosage accurately and safely, minimizing potential risks or errors.

This document provides step-by-step instructions for setting up, operating, and maintaining the equipment. It covers essential features, offering users clear guidance to optimize its functionality. Whether it’s about preparing the device or troubleshooting issues, the guide equips users with the knowledge needed for efficient performance.

Each section is tailored to clarify various aspects of the tool, from its basic setup to advanced features. Proper care and handling not only ensure the longevity of the device but also contribute to delivering medical solutions with precision. Make sure to follow all instructions carefully to guarantee optimal results.

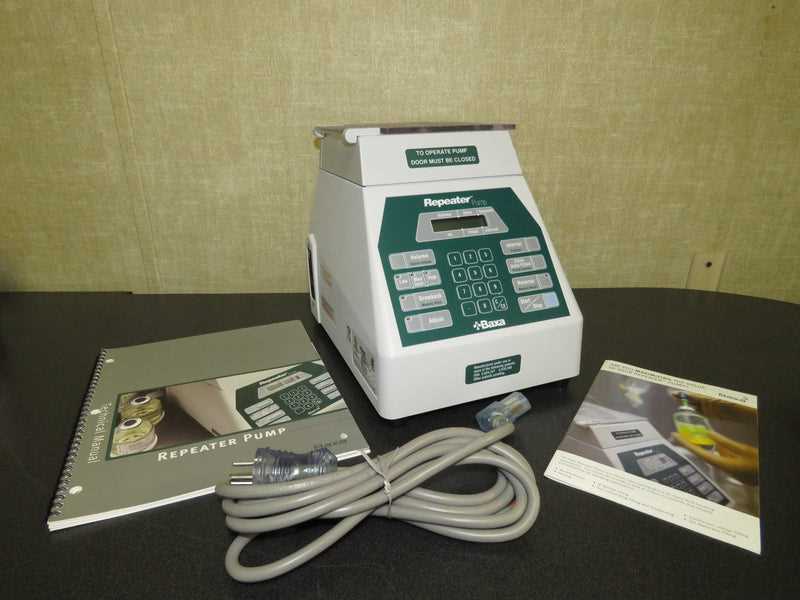

Understanding the Basics of the Baxter Repeater Pump

The device designed for precise fluid management is essential in various medical settings. It helps healthcare professionals deliver liquids with accuracy and consistency, ensuring patient safety and treatment efficacy. By understanding the key functionalities of this equipment, users can ensure optimal performance and long-term reliability.

Key Components

The main elements of this system work together to ensure smooth operation. Each part plays a crucial role in delivering fluids efficiently, and understanding them can prevent common operational issues.

- Control Panel: The interface for adjusting settings, monitoring processes, and handling alerts.

- Delivery Mechanism: The core system responsible for accurate flow regulation.

- Safety Features: Integrated systems to prevent errors and ensure patient safety during use.

Basic Operation Principles

Effective use of the equipment relies on a clear understanding of its operational steps. Below are the general principles for proper utilization:

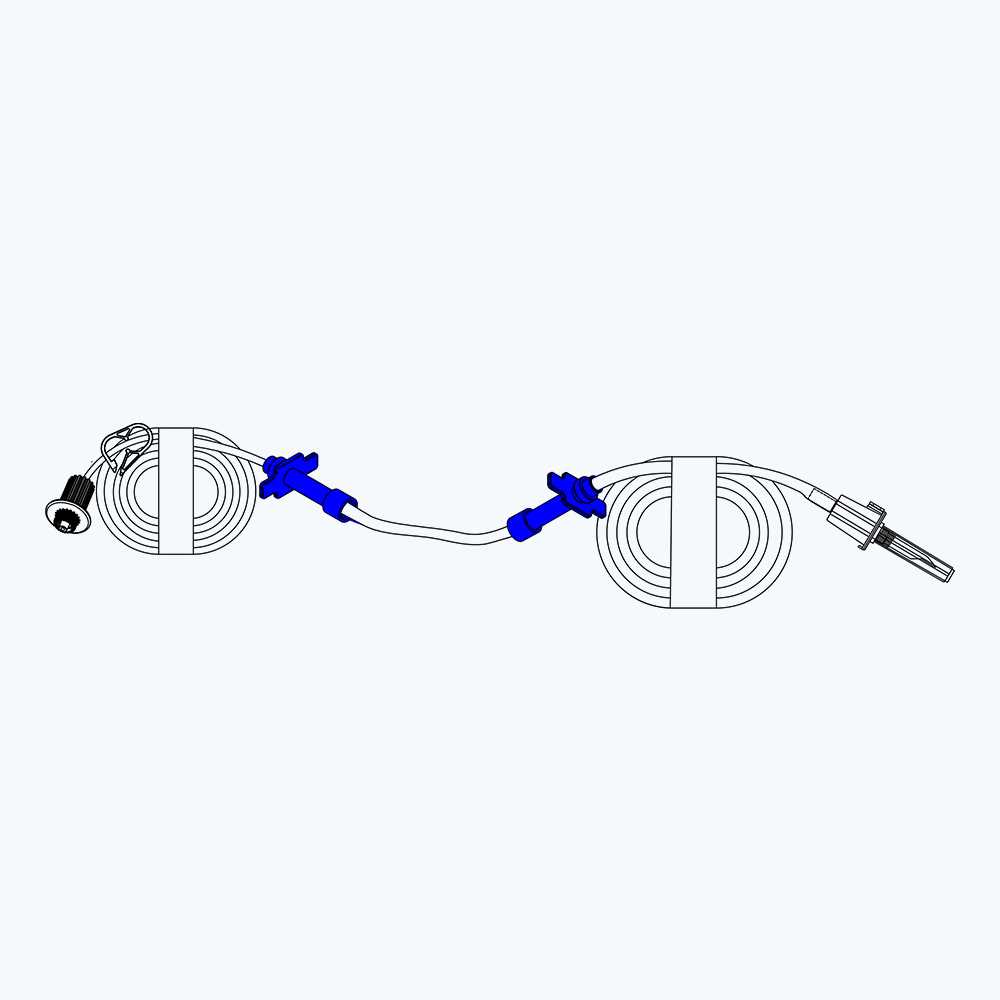

- Setting up the device by connecting the necessary tubing and containers.

- Configuring the desired parameters, such as volume and rate of delivery.

- Monitoring the progress through the display and ensuring fluid levels remain adequate.

By following these guidelines, users can ensure that the system operates efficiently, providing consistent and safe performance in medical environments.

Key Features and Components Overview

The device offers a range of essential functionalities that ensure precise operation and enhance user experience. Understanding its main elements is crucial for efficient use and maintenance. Below is an outline of the primary features and components, focusing on how they contribute to optimal performance.

Core Functions: This unit is designed to deliver accurate, consistent output. Its core capabilities are tailored to support various tasks, ensuring reliability across different applications.

User Interface: The control panel is intuitive, allowing for straightforward adjustments and monitoring. Key indicators provide real-time feedback, ensuring full control during operation.

Safety Features: Safety mechanisms are integrated to prevent errors, protecting both the user and the equipment from potential mishaps. Alarms and automatic shut-off options are built in to mitigate risks during use.

Durable Construction: Crafted from robust materials, the structure is built to withstand prolonged use, ensuring longevity and reducing the need for frequent maintenance.

Key Components: The system consists of several integral parts, including a control unit, sensors, and connectors, each playing a pivotal role in its overall functionality. Each element works in harmony to achieve smooth and reliable operation.

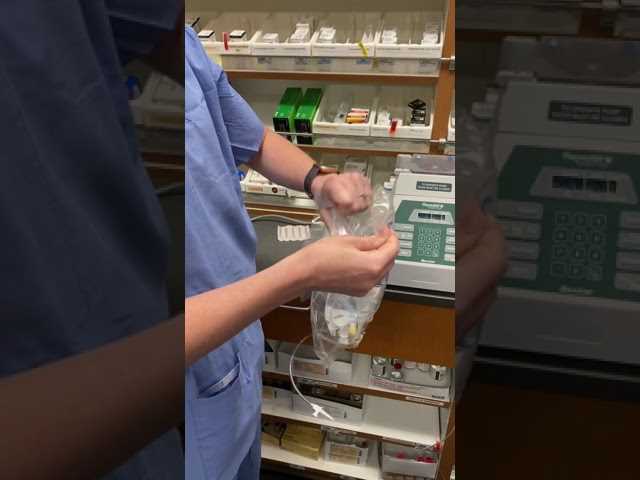

Setting Up the Baxter Repeater Pump

Proper preparation of this medical device is crucial for ensuring accurate and efficient operation. Before beginning the setup process, it’s important to understand the key steps and components that will guide you through the process. This section will outline how to configure the equipment for use in medical environments where fluid transfer or administration is required.

Step 1: Begin by assembling the necessary accessories and parts required for the machine’s function. Ensure that all components are present and undamaged before proceeding. Check the power supply and make sure it is connected securely.

Step 2: Connect the tubing to the appropriate ports. Make sure that each line is attached correctly to prevent leaks or interruptions during operation. The tubing should be primed to remove any air, ensuring smooth flow during use.

Step 3: Calibrate the device according to the volume and rate of fluid to be handled. Adjust the settings based on specific medical needs. This may involve setting the flow rate, volume limits, or other parameters to ensure accuracy.

Step 4: Perform a safety check before operation. Verify that the device is functioning as expected, and confirm that all safety alarms or notifications are active and responsive.

By following these steps, the device will be ready for use, providing reliable and precise performance in a healthcare setting.

How to Program the Pump for Use

Proper setup is essential to ensure efficient and safe operation of the device. Before starting, it’s important to configure the settings based on specific requirements. This section will guide you through the programming process, ensuring the correct parameters are entered to meet your operational needs.

- Ensure that the device is powered on and all necessary components are correctly connected.

- Access the main menu by pressing the designated button or navigating through the display interface.

- Select the appropriate mode of operation, such as continuous or intermittent flow, depending on the intended usage.

- Enter the required dosage or flow rate, adjusting it according to the provided instructions or medical guidelines.

- Set the duration for the operation, ensuring that the timing aligns with the planned therapy or procedure.

- Review all programmed settings to confirm accuracy, as incorrect parameters may impact performance.

- Once all values are confirmed, save the settings and initiate the process by pressing the start or run button.

Following these steps carefully ensures that the device is programmed according to the specific needs, minimizing the risk of errors and ensuring smooth functionality.

Maintenance Tips to Ensure Optimal Performance

Proper upkeep is essential to keep equipment running smoothly and efficiently. Regular maintenance not only extends the lifespan of the device but also ensures it operates at peak performance. Consistent care involves a combination of routine checks, cleaning procedures, and timely replacements of worn parts.

Firstly, inspect the equipment periodically for any signs of wear or damage. Addressing minor issues promptly can prevent them from escalating into major problems. Ensure that all connections and fittings are secure and free from leaks, as these can significantly affect performance.

Additionally, keep the system clean and free of debris. Accumulation of dirt and contaminants can impair functionality and lead to reduced efficiency. Follow the recommended cleaning schedule and use appropriate cleaning agents to avoid any damage.

Regularly review and replace consumable parts according to the manufacturer’s recommendations. Worn or outdated components can cause operational issues and compromise the overall effectiveness of the equipment.

Lastly, ensure that the equipment is operating under optimal conditions. Adhering to the specified operational parameters and avoiding overuse or misuse can help maintain its performance and reliability over time.

Common Troubleshooting Tips for Users

When operating complex equipment, occasional issues may arise that hinder optimal performance. Addressing these common problems can often be straightforward with a few basic steps. This section provides guidance on identifying and resolving frequent difficulties encountered during use.

1. Equipment Not Starting

If the device fails to power on, ensure that it is properly connected to a power source. Check the power cord and outlet for any signs of damage or loose connections. Also, verify that the power switch is in the “on” position and that any necessary fuses or breakers are functioning correctly.

2. Unusual Noises

Unexpected sounds can indicate internal issues. First, check for any foreign objects or debris that may be obstructing moving parts. If the noise persists, it may be necessary to inspect the internal components for wear or damage, and consult a technician if needed.

3. Inconsistent Output

If the performance of the unit is irregular, such as fluctuating output or efficiency, inspect the settings and ensure they are configured correctly for the task. Additionally, verify that all connections and components are secure and functioning properly.

4. Leaks or Fluid Issues

Leaks can compromise the functionality of the equipment. Examine all seals and connections for signs of wear or damage. Ensure that fluids are at appropriate levels and that no blockages are present in the fluid pathways.

5. Error Messages

Error codes or messages displayed on the unit should be referenced against the troubleshooting guide provided with the equipment. Follow the recommended steps to address specific errors, which may include resetting the system or performing maintenance tasks.

By systematically addressing these common concerns, users can often resolve issues independently and maintain efficient operation of their equipment.

Safety Precautions During Operation

Ensuring safety while using any complex device or machinery is crucial to avoid accidents and ensure smooth functionality. Proper safety measures are essential to protect both the operator and the equipment from potential hazards. This section outlines key practices to follow during the operation of such devices.

- Always read and understand the operational guidelines before starting the device.

- Wear appropriate personal protective equipment (PPE), such as gloves and safety glasses, to shield yourself from any potential risks.

- Verify that the equipment is in good working condition before each use, checking for any signs of damage or wear.

- Ensure that all connections and components are securely attached and properly installed.

- Keep the work area clean and free of any obstructions that could interfere with the operation.

During operation, it is important to:

- Monitor the device closely to identify any unusual noises or vibrations that may indicate a malfunction.

- Operate the equipment within the recommended parameters to prevent overloading or excessive strain.

- In case of an emergency, be familiar with the shutdown procedures to quickly and safely turn off the device.

- Never bypass safety features or override built-in protective mechanisms.

- Regularly review and adhere to any additional safety guidelines specific to the equipment being used.

Following these precautions helps to ensure a safe operating environment and prolong the lifespan of the equipment. Always prioritize safety to prevent accidents and maintain optimal performance.