Delicate mechanisms require specialized tools to ensure their maintenance and functionality. Whether dealing with intricate timepieces or other fine devices, understanding how to effectively utilize a precision toolkit is crucial for preserving their integrity and prolonging their life.

This guide is designed to provide detailed insights into the proper use of each instrument within your toolkit. With step-by-step explanations, even the most complex procedures become manageable. It empowers you with the knowledge to handle your tools with confidence, ensuring successful outcomes every time.

Mastering the art of fine-tuning these small yet vital components can seem daunting at first. However, with a solid understanding of the tools at your disposal and a methodical approach, the process becomes significantly more approachable. This guide aims to simplify the complexities, providing clear and concise directions for each task.

Throughout this guide, you will find essential tips and expert advice that enhance your proficiency with your toolkit. By following these instructions, you’ll not only complete each task with precision but also gain a deeper appreciation for the delicate engineering behind these remarkable devices.

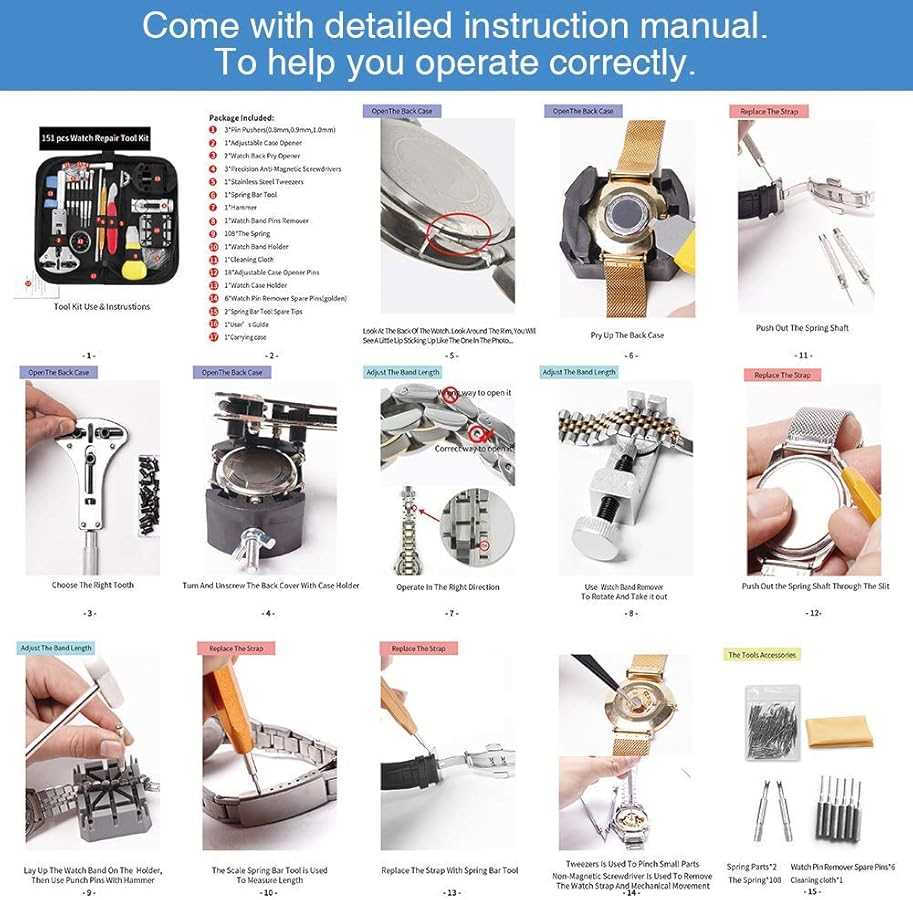

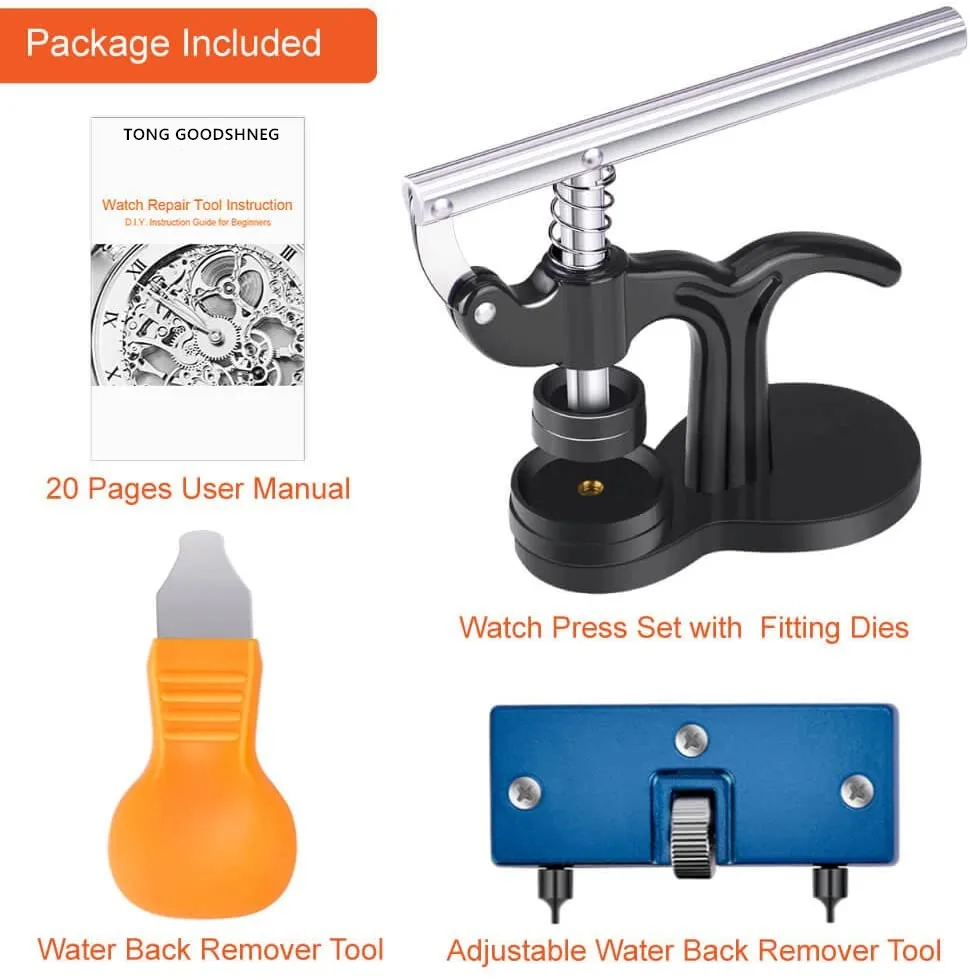

Essential Tools in a Watch Repair Kit

The world of horology requires a precise and varied set of instruments. Each piece serves a unique purpose, contributing to the meticulous process of timepiece maintenance and adjustment. Understanding the importance and function of these essential items is crucial for anyone aiming to master the art of horology.

| Tool | Purpose |

|---|---|

| Precision Screwdrivers | Used for loosening and tightening the small screws found in timepieces. |

| Spring Bar Tool | Designed to remove and insert the spring bars that secure the bracelet or strap to the case. |

| Case Back Opener | Facilitates the removal of the back casing, allowing access to the internal components. |

| Tweezers | Fine-tipped for handling small, delicate components with precision. |

| Movement Holder | Provides a stable base to securely hold the movement during servicing or inspection. |

| Loupe | Offers magnification, crucial for detailed inspection of tiny parts and mechanisms. |

| Pin Punches | Utilized for removing pins from the bracelet, especially when adjusting the length. |

Familiarity with these tools and their applications is essential for ensuring the accuracy and longevity of a timepiece. Each instrument plays a critical role in the delicate procedures involved in maintaining and adjusting these intricate devices.

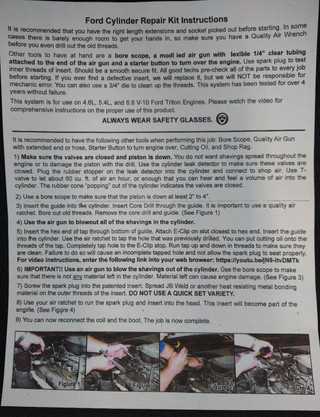

Step-by-Step Guide to Disassembling a Watch

Understanding how to carefully take apart your timepiece is essential for anyone looking to maintain or explore its inner workings. This guide will walk you through the key stages of safely dismantling each component, ensuring that all parts remain intact and ready for future use.

1. Preparing the Workspace

- Choose a clean, well-lit area to work.

- Ensure you have a soft surface to avoid scratches or damage to small parts.

- Gather all necessary tools, such as precision screwdrivers and tweezers.

2. Removing the Back Cover

- Identify the type of back cover (screw-down, snap-off, etc.).

- Use the appropriate tool to carefully loosen and remove the cover.

- Set the cover aside in a secure place.

3. Extracting the Movement

- Carefully lift the crown to disengage it from the mechanism.

- Gently release the movement from its casing using a pair of tweezers.

- Place the mechanism in a safe, dust-free container.

4. Detaching the Hands

- Use a hand removal tool to gently lift the hands off their posts.

- Start with the second hand, followed by the minute and hour hands.

- Ensure all hands are stored safely to prevent bending or damage.

5. Separating the Dial

- Identify and loosen the screws holding the dial in place.

- Carefully lift the dial off the movement.

- Store the dial in a dust-free environment.

By following these steps methodically, you can safely disassemble the timepiece and prepare it for further inspection, cleaning, or modifications.

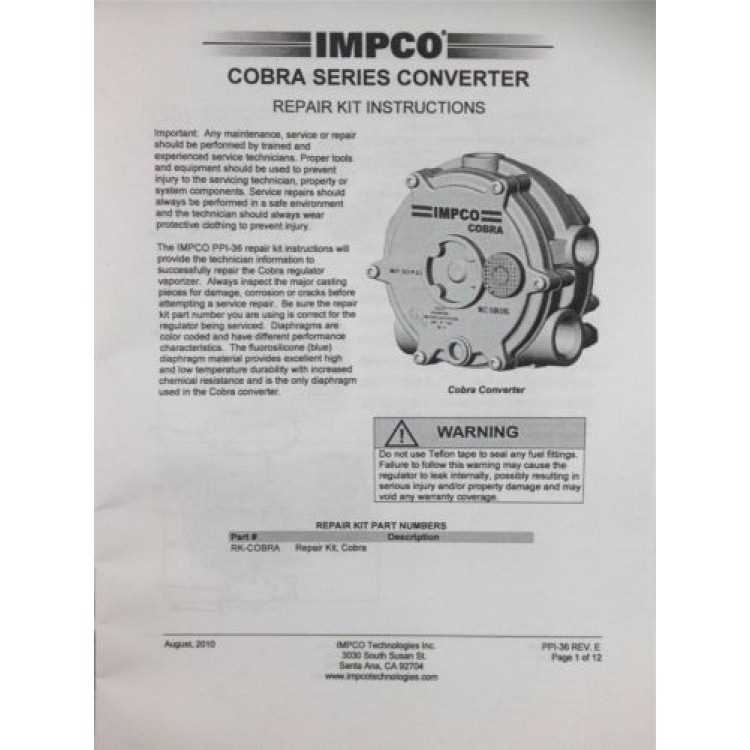

How to Replace a Watch Battery

Changing the power source in your timepiece is a straightforward process that can be done with a few simple tools. By following these steps, you’ll ensure your device continues to function smoothly. Below is a guide that will help you complete this task effectively.

Step 1: Gather Necessary Tools

- Small screwdriver or case opener

- Tweezers

- New power cell

Step 2: Open the Back Case

- Locate the back cover of your device. Depending on the model, it may be snapped, screwed, or twisted on.

- If the cover is snapped on, gently use a case opener or small screwdriver to pry it open.

- For screw-down covers, use a small screwdriver to remove the screws carefully. Ensure you keep them safe.

Step 3: Remove the Old Battery

- Using tweezers, gently lift the old power cell from its compartment.

- Note the orientation of the battery before removal to ensure proper placement of the new one.

Step 4: Insert the New Battery

- Place the new power cell into the compartment, ensuring it matches the original orientation.

- Use tweezers to position it without touching the contacts directly, which could cause corrosion.

Step 5: Close the Back Case

- Align the back cover with the case.

- Snap it back into place, or screw it down securely.

- Check that the cover is firmly in place to prevent moisture or dust from entering.

Once completed, your timepiece should be working with renewed energy. If it does not, double-check the power cell orientation and ensure the cover is properly sealed.

Proper Techniques for Adjusting Watch Bands

To ensure a comfortable fit and extend the lifespan of your timepiece, it is essential to correctly alter the length of the bracelet or strap. Whether working with a metal link design or a leather strap, using the right approach can prevent damage and maintain the original appearance of the accessory.

For metal link designs, start by carefully identifying the removable segments. Use a small, precise tool to push out the pins or screws that hold the segments together. When removing links, ensure that the total number taken out is even, balancing the band to maintain the clasp centered on the wrist. After removing the desired segments, reattach the remaining sections with the same level of care, ensuring that all pins or screws are securely fastened.

If adjusting a leather or fabric strap, focus on selecting the correct notch for the buckle. The strap should be adjusted gradually, checking the fit frequently to avoid overstretching or damaging the material. If additional holes are required, use a hole punch designed specifically for this purpose, ensuring that the new holes align perfectly with the existing ones.

After completing any adjustments, test the fit to confirm that it is both comfortable and secure. A properly adjusted band not only enhances comfort but also ensures the reliable performance of your accessory over time.

Common Issues and Their Solutions

In the realm of timepiece maintenance, various challenges can arise that may hinder the performance of your device. Understanding how to address these problems effectively can help ensure longevity and accuracy. This section delves into typical issues encountered and provides practical solutions to resolve them.

Battery-Related Problems

One of the most frequent issues is related to the power source. If the timepiece suddenly stops or exhibits irregular behavior, the battery might be the culprit. Replacing the battery is often a straightforward solution. Ensure you use the correct type and follow proper handling procedures to avoid damage.

Accuracy and Timekeeping Issues

If your timepiece begins to lose or gain time, it may require adjustment or calibration. Regular servicing by a professional can correct these discrepancies. Additionally, check for any obstructions or dirt affecting the movement, as these can also impact precision.

Maintenance Tips for Your Watch Repair Tools

Proper care and upkeep of your precision instruments are essential for ensuring their longevity and optimal performance. By following a few key practices, you can maintain the functionality and accuracy of your equipment. Regular attention to these tools will prevent wear and tear, and preserve their reliability for all your delicate tasks.

1. Clean Regularly: After each use, make sure to clean your tools thoroughly to remove any dust, grime, or residues. This helps prevent the accumulation of debris that could impair their operation or cause damage. Use appropriate cleaning solutions and soft cloths to avoid scratches and ensure a thorough cleanse.

2. Store Properly: Ensure that your instruments are stored in a dry, dust-free environment. Use protective cases or padded compartments to prevent accidental damage and exposure to elements that might cause rust or corrosion. Keeping your tools organized can also help you avoid misplacing any components.

3. Inspect Regularly: Conduct periodic inspections to check for any signs of wear or malfunction. Look for loose parts, frayed components, or any unusual changes in performance. Early detection of issues allows for timely repairs or replacements, which can save you from more significant problems in the future.

4. Lubricate Moving Parts: For tools with moving parts, apply appropriate lubricants to ensure smooth operation and to reduce friction. This helps in maintaining the precision and extending the life of these parts. Be sure to use lubricants recommended by the manufacturer to avoid potential damage.

5. Handle with Care: Always handle your instruments gently and with care. Avoid applying excessive force or using them for tasks they are not designed for. Proper handling reduces the risk of damage and ensures that your tools remain in optimal working condition.