In many industrial and medical settings, ensuring the precise and consistent movement of fluids is crucial for various processes. Reliable equipment designed to handle the delicate task of transferring liquids plays a pivotal role in maintaining efficiency and accuracy. Understanding the mechanisms and operation of such devices can significantly enhance their usage and contribute to better outcomes.

Whether it’s for small-scale operations or more extensive systems, comprehending the proper methods and techniques for handling these tools is essential. The following sections will provide valuable insights into the fundamental aspects of these systems, offering guidance on how to optimize their performance in different scenarios.

Comprehensive Guide to Setting Up Your Pump

Proper setup is essential for ensuring that your system operates efficiently and reliably. This guide will walk you through the critical steps involved in configuring your equipment for optimal performance. Attention to detail during installation will help you avoid potential is

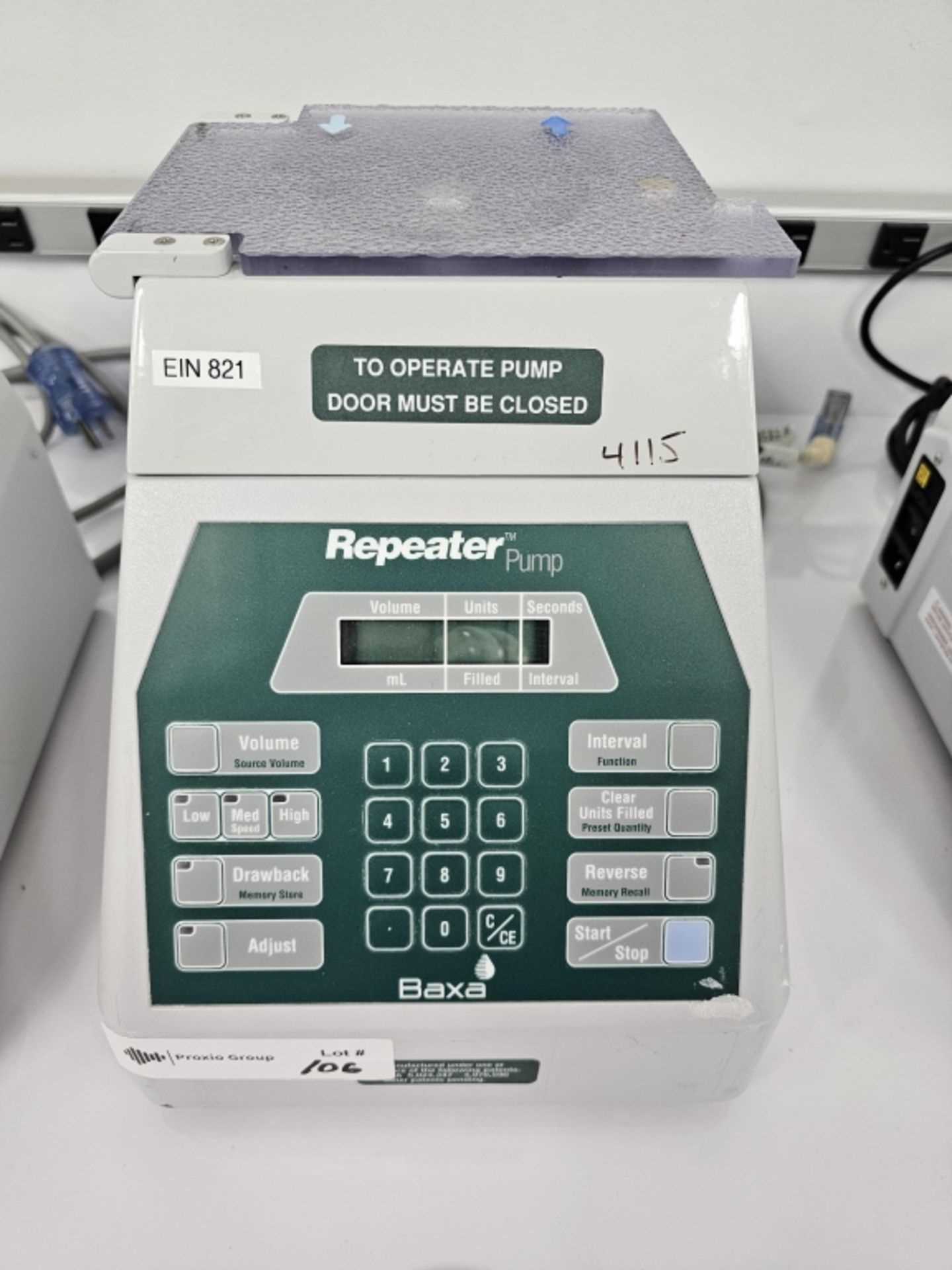

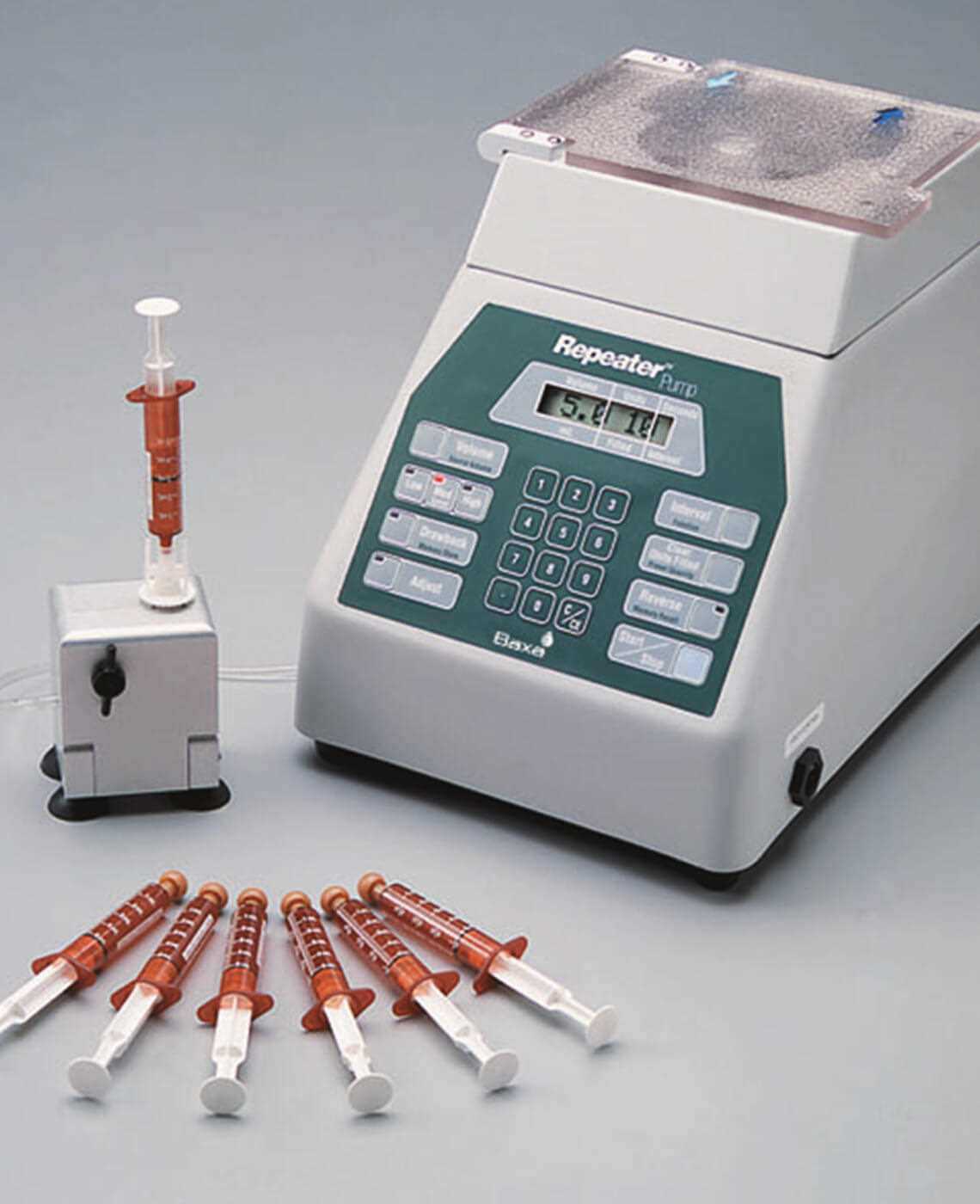

Key Features of the Repeater Pump System

This section explores the core attributes of the innovative fluid handling system designed for precise and efficient operation. It highlights how the system’s advanced design enhances reliability, accuracy, and ease of use in various applications.

Precision and Control

The system is engineered for unparalleled precision, offering fine control over the fluid dispensing process. It integrates sophisticated technology to ensure accurate measurement and consistent flow rates, which is crucial for applications requiring meticulous attention to detail.

Ease of Maintenance and Operation

Designed with user convenience in mind, the system boasts a streamlined interface that simplifies operation and reduces the learning curve. Maintenance is also facilitated by easy access to critical components, ensuring that the system remains in optimal working condition with minimal effort.

Step-by-Step Installation Instructions

This section provides a comprehensive guide to setting up your device correctly. Following these detailed steps will ensure that the equipment operates efficiently and safely.

- Preparation: Gather all necessary tools and components before starting the setup process. Ensure that you have a clear workspace and that the area is free from any obstructions.

- Assembly: Begin by assembling the main components. Refer to the component diagram to identify each part and their respective connections. Securely fasten all components according to the provided diagrams.

- Connection: Connect the device to the appropriate power source. Verify that the power supply matches the specifications outlined in the product documentation. Ensure all electrical connections are tight and secure.

- Testing: Once assembled and connected, perform a preliminary test to check for proper functionality. Follow the testing procedures to confirm that the device operates as intended. Address any issues or irregularities before proceeding.

- Final Adjustments: Make any necessary adjustments to optimize performance. This may include calibrating settings or fine-tuning connections. Ensure that all adjustments are in accordance with the recommended settings.

- Completion: After final adjustments, perform a final check to ensure that everything is correctly installed and functioning. Clean up the workspace and dispose of any packaging materials properly.

By adhering to these steps, you will ensure a successful setup and reliable operation of your equipment. For any additional support, consult the troubleshooting section or contact customer service for assistance.

Common Troubleshooting Tips and Solutions

When dealing with issues in fluid transfer systems, it’s crucial to address common problems systematically. Identifying the root causes of malfunctions can save time and ensure smooth operation. Here are some practical tips to help resolve frequent issues encountered in such systems.

Checking and Resolving Leaks

Leaks are a common issue that can affect the efficiency of the system. Begin by inspecting all connections and joints for any signs of fluid escaping. Ensure that all seals and gaskets are intact and properly fitted. If a leak is detected, tightening fittings or replacing damaged seals can often resolve the problem.

Addressing Airlocks and Blockages

Airlocks and blockages can hinder the flow of fluids, causing inconsistent performance. To address airlocks, gently tap the system or use a priming method to release trapped air. For blockages, check for obstructions in the lines and remove any debris that may be causing the restriction. Regular maintenance and cleaning can help prevent these issues from recurring.

By following these guidelines, you can effectively troubleshoot and resolve common problems, ensuring that your system operates efficiently and reliably.

Maintenance Practices for Optimal Performance

To ensure consistent efficiency and longevity of your fluid transfer system, regular upkeep is essential. Proper care not only extends the life of the equipment but also maintains its reliability and accuracy. This section outlines key practices that should be followed to achieve the best performance from your system.

Regular maintenance involves checking and servicing various components to prevent potential issues before they arise. Adhering to a scheduled maintenance plan helps in identifying wear and tear early, thus avoiding unexpected breakdowns and costly repairs.

| Task | Description | Frequency |

|---|---|---|

| Inspection | Examine all components for signs of wear, leakage, or damage. Ensure that all connections are secure. | Weekly |

| Cleaning | Remove any residue or buildup from the system to prevent clogging and maintain smooth operation. | Monthly |

| Lubrication | Apply appropriate lubricants to moving parts to reduce friction and prevent excessive wear. | Quarterly |

| Calibration | Verify that the system is functioning within specified parameters and adjust settings as needed to ensure accurate performance. | Annually |

| Replacement of Worn Parts | Replace any components that show signs of significant wear or degradation to prevent system failure. | As Needed |

By adhering to these maintenance guidelines, you can optimize the performance and durability of your fluid transfer system. Regular attention to these tasks will help you avoid potential issues and ensure reliable operation over the long term.

Safety Precautions for Effective Use

Ensuring the secure and proper operation of any equipment involves adhering to essential safety guidelines. Proper precautions not only protect the user but also enhance the efficiency and longevity of the device. It is crucial to follow these guidelines to avoid accidents and achieve optimal performance.

Firstly, always familiarize yourself with the equipment before use. Understanding its components and functionalities helps in operating it safely. Ensure that all parts are correctly assembled and that there are no visible signs of damage. Regular inspections and maintenance are vital to detect any issues before they lead to malfunctions.

Additionally, use the equipment only for its intended purpose. Improper use can result in accidents or damage. Ensure that all safety features are functioning correctly and follow the manufacturer’s recommendations for operation. Avoid bypassing any safety mechanisms or attempting unauthorized modifications.

Wearing appropriate personal protective equipment is also important. Depending on the nature of the device, this may include gloves, goggles, or other safety gear. This helps to protect against potential hazards during operation.

Finally, always adhere to the recommended procedures for handling and disposing of any substances or materials involved. Proper storage and disposal practices help to minimize risks and contribute to a safer working environment.