When working with advanced optical sensors, having a comprehensive resource at your disposal is crucial for effective utilization. This guide provides detailed insights into the functionality, setup, and maintenance of the GL-R series devices, helping users navigate through their features with ease.

In this section, you’ll find valuable information designed to assist you in understanding how to operate and troubleshoot these high-performance sensors. The content is structured to ensure that both new and experienced users can access essential details to enhance their operational efficiency and resolve any issues they may encounter.

Understanding Keyence GL-R Basics

This section aims to provide a foundational overview of the GL-R series, focusing on its core functionalities and features. Readers will gain insight into how these devices operate and their basic setup procedures, ensuring a clear understanding of their essential aspects.

Here are some fundamental elements to consider:

- Device Overview: Learn about the main components and their roles within the system.

- Setup Procedures: Understand the initial configuration steps required to get the device operational.

- Operation Guidelines: Explore how to use the device effectively for optimal performance.

Grasping these basics will facilitate a smoother integration and usage of the equipment, leading to more efficient outcomes in its application.

Features and Specifications Overview

This section provides an in-depth look into the primary characteristics and technical details of the device. Understanding these elements is crucial for assessing its capabilities and how it fits specific needs.

| Feature | Description |

|---|---|

| Measurement Range | Details the range within which the device can accurately measure. |

| Accuracy | Indicates the precision of measurements provided by the device. |

| Operating Temperature | Describes the temperature range in which the device operates effectively. |

| Display Type | Specifies the type of display used for showing measurement results. |

| Connectivity Options | Lists the available methods for connecting the device to other systems or networks. |

Getting Started with Keyence GL-R

Embarking on the journey with the GL-R series involves understanding its core features and functionality. This guide aims to provide an overview of initial steps to set up and utilize this equipment effectively. By following these guidelines, users can ensure they are well-prepared to take full advantage of the device’s capabilities.

First, familiarize yourself with the main components and their roles. It is crucial to connect the device correctly to ensure proper operation. Next, configure the settings according to your specific needs to achieve optimal performance. Lastly, performing a few basic tests will help verify that everything is functioning as expected.

How to Install Keyence GL-R

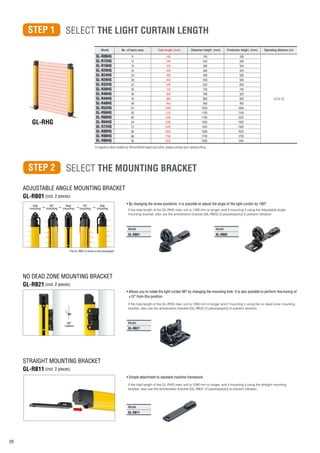

Installing this optical sensor involves several steps to ensure proper setup and functionality. Begin by identifying the appropriate location for mounting the device, ensuring it aligns with your system’s requirements. Proper installation is crucial for optimal performance and accurate measurements.

Start by securely attaching the sensor to the designated mount using the provided hardware. Make sure the sensor is positioned correctly according to the guidelines provided for alignment and orientation. Next, connect the necessary wiring, ensuring all connections are firm and secure to prevent any operational issues.

Once the device is physically mounted and wired, proceed to configure the settings as required by your application. Follow the provided guidelines to adjust the parameters and calibrate the sensor for accurate readings. Finally, test the setup to confirm everything is functioning as expected and make any necessary adjustments.

Configuring Keyence GL-R for Use

Setting up a detection system for optimal performance involves a series of precise steps to ensure accurate and reliable operation. This process typically includes adjusting various parameters and connecting the necessary components to achieve the desired functionality. By following the correct procedures, users can tailor the system to meet specific needs and enhance its effectiveness in various applications.

Initial Setup

Begin by mounting the device in the intended location, ensuring it is securely fastened and properly aligned. Connect the system to the power source and verify that all connections are correctly established. It’s crucial to follow the manufacturer’s guidelines for wiring to prevent any operational issues. Once powered on, the device will usually perform a self-check to confirm that all components are functioning correctly.

Parameter Configuration

Access the configuration interface to set the parameters according to your application’s requirements. This may involve adjusting sensitivity levels, response times, and output settings. Consult the provided documentation to understand each setting’s impact on performance. After making the necessary adjustments, test the system to ensure it responds accurately to the target objects or conditions.

Maintenance and Troubleshooting Tips

Proper upkeep and problem-solving strategies are crucial to ensure the efficient operation of your equipment. Regular maintenance and swift resolution of issues can enhance performance and extend the lifespan of your device. This section provides essential guidelines to help you maintain optimal functionality and address common challenges effectively.

Routine Maintenance Practices

Adhering to a consistent maintenance schedule is key to preventing potential problems. Consider the following practices:

- Inspect the equipment periodically for signs of wear or damage.

- Clean all accessible parts regularly to avoid buildup of debris or dirt.

- Check and replace worn components as necessary.

- Ensure that connections and cables are secure and free from corrosion.

- Verify that software or firmware is up-to-date with the latest versions.

Troubleshooting Common Issues

When issues arise, prompt troubleshooting can mitigate downtime. Here are steps to diagnose and address frequent problems:

- Device Not Powering On:

- Check if the power source is active and connections are properly made.

- Inspect the power cord and connectors for damage.

- Try restarting the device to reset internal components.

- Performance Degradation:

- Review system logs for error messages or warnings.

- Ensure that the device is not overheating and that ventilation is adequate.

- Run diagnostic tests to identify and address specific issues.

- Communication Failures:

- Confirm that all network connections are stable and properly configured.

- Check for any software conflicts or updates that might be needed.

- Restart the device and associated network equipment to refresh connections.

By following these maintenance and troubleshooting recommendations, you can ensure reliable operation and minimize disruptions to your workflow. Regular attention to these aspects will help maintain peak performance and prolong the life of your equipment.

Advanced Applications of Keyence GL-R

Exploring the more sophisticated uses of industrial sensors can greatly enhance productivity and precision in various manufacturing processes. By leveraging these advanced capabilities, operations can achieve greater efficiency and accuracy, ensuring that complex tasks are managed with ease and reliability. This section delves into how these sensors can be applied in complex environments to optimize performance and address specific challenges faced in automation and quality control.

Enhanced Quality Control

One of the significant advancements is the ability to fine-tune quality control mechanisms. These sensors can be utilized to monitor minute variations in product dimensions and characteristics, enabling real-time adjustments and maintaining high standards. For instance, they can be employed in inspection stations where precise measurement of parts is crucial. This real-time feedback loop allows for immediate corrections, reducing waste and ensuring consistent product quality.

Integration with Complex Systems

Advanced models are designed to seamlessly integrate with sophisticated automation systems. They can be interfaced with programmable controllers and data acquisition systems, providing a cohesive solution for managing complex operations. By incorporating these sensors into a broader system, users can automate intricate processes, collect detailed data, and perform comprehensive analysis. This integration enhances overall system performance and enables more advanced control strategies.

| Application | Benefit | Example |

|---|---|---|

| Quality Control | Improved precision and reduced waste | Real-time dimensional checks in a production line |

| System Integration | Enhanced automation and data collection | Linking sensors with programmable logic controllers |

| Real-time Feedback | Immediate adjustments and process optimization | Dynamic responses to deviations in manufacturing processes |