When working with advanced fogging devices, understanding the optimal way to operate and maintain them is crucial for achieving the best results. Whether you are new to this type of equipment or looking to refresh your knowledge, having a clear and concise resource is essential. This guide provides a thorough explanation of the key features, operation techniques, and essential care practices required for maintaining peak performance over time.

Effective utilization of this equipment relies not only on knowing how to start and operate it but also on being familiar with the specific components and their roles. This section breaks down each part, offering detailed insights into its function and importance. By following the guidelines provided, users can ensure that their equipment runs smoothly and efficiently, reducing the likelihood of issues and extending its lifespan.

Maintenance plays a pivotal role in ensuring longevity and consistent performance. Regular upkeep, including cleaning and checking for wear and tear, is necessary to prevent unexpected malfunctions. This section covers the most important maintenance tasks that should be performed, along with tips on how to identify and address common problems before they escalate.

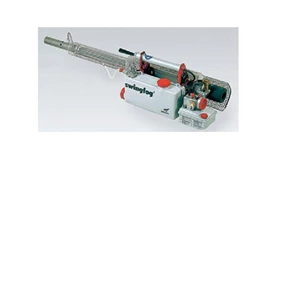

Overview of the Swingfog SN50 Device

The device in question is a versatile tool designed for efficient and effective dispersal of liquids into fine mists. This equipment is frequently utilized in various applications, including pest control, disinfection, and other situations where precise and thorough fogging is required. It is engineered to operate under demanding conditions, providing reliable performance and consistent results.

Key Features of this apparatus include its ability to produce a dense fog, capable of reaching into difficult-to-access areas, ensuring comprehensive coverage. The unit is built with durability in mind, incorporating materials that withstand high temperatures and extended use. Additionally, the machine’s design allows for ease of use, making it accessible to both professional operators and those less experienced.

Performance and Efficiency are at the core of this device’s design. Its capability to atomize liquids into ultra-fine particles ensures minimal waste and maximum impact. The tool’s power system supports continuous operation, which is crucial for large-scale tasks. Furthermore, the design optimizes fuel consumption, contributing to cost-effectiveness while maintaining high output.

In summary, this fogging machine is a robust and efficient solution for a wide range of fogging tasks, offering reliability, ease of use, and exceptional performance in various operational environments.

Setting Up Your Fogging Machine

Proper preparation is key to ensuring the efficient operation of your fogging device. Before beginning, it’s important to familiarize yourself with the basic setup procedures, ensuring that all components are correctly assembled and ready for use. This will not only optimize the machine’s performance but also enhance its longevity.

Start by inspecting all parts for any visible signs of damage or wear. Ensure that all connections are secure, and that the necessary fuel or chemical solutions are prepared according to the recommended specifications. Carefully follow the steps to assemble the machine, paying close attention to each connection point, as proper alignment is crucial for safe and effective operation.

Once assembled, perform a preliminary test in a safe, open area to verify that the device functions as expected. Monitor the machine’s performance closely, checking for any unusual behavior, such as leaks or irregular output. Adjust settings as needed to achieve the desired fogging intensity and coverage.

Finally, ensure that all safety protocols are followed during setup. This includes wearing appropriate protective gear, maintaining a safe distance from the fogging area, and ensuring proper ventilation. With these steps completed, your fogging machine will be ready to operate efficiently, providing the desired results with minimal issues.

Essential Safety Precautions for Operators

Proper operation of any equipment requires a strong emphasis on safety to prevent accidents and ensure the well-being of both the operator and those around them. It is crucial to adhere to key safety measures to avoid hazards, injuries, and equipment damage.

Protective Gear

Wearing the appropriate protective gear is fundamental to personal safety. Operators should always be equipped with the following:

- Eye Protection: Use safety goggles or a face shield to guard against debris and harmful substances.

- Respiratory Protection: A quality mask or respirator is essential to prevent inhalation of fumes or particles.

- Protective Clothing: Wear long sleeves, gloves, and boots to minimize skin exposure.

Operational Safety Guidelines

When handling and operating machinery, following these guidelines will help ensure safe and effective use:

- Pre-Operation Check: Inspect the equipment thoroughly before each use. Ensure that all components are in proper working order and free of damage.

- Clear the Area: Ensure the work area is clear of any obstructions and that bystanders are at a safe distance before starting the operation.

- Proper Handling: Maintain a firm grip on the equipment and use it according to the manufacturer’s guidelines, avoiding any unauthorized modifications.

- Ventilation: Operate the equipment in a well-ventilated area to prevent the buildup of harmful fumes.

- Emergency Procedures: Familiarize yourself with emergency shutdown procedures and have a fire extinguisher readily available.

By adhering to these safety precautions, operators can significantly reduce the risk of accidents and maintain a secure working environment.

Step-by-Step Operating Instructions

This guide provides a clear sequence of actions to ensure the correct and safe operation of your equipment. The steps outlined below are designed to help users navigate the process efficiently, ensuring optimal performance and safety.

Preparation and Setup

Before beginning, ensure that all necessary safety measures are in place. Check that the equipment is in good working condition, and confirm that all required materials are readily available. Proper setup is essential to avoid interruptions during operation.

Operating Procedure

1. Initiate the Power Supply: Engage the power by following the specific steps for your device, ensuring a stable and continuous energy flow.

2. Adjust Settings: Configure the operational parameters according to your requirements. This might include adjusting the output levels, setting the timer, or selecting the appropriate mode.

3. Start the Process: Activate the main function by engaging the start mechanism. Monitor the process closely during the initial stages to ensure everything functions as expected.

4. Monitoring: Throughout the operation, keep an eye on the indicators and gauges. Adjust settings if necessary to maintain optimal performance.

5. Shutdown: Once the task is complete, carefully shut down the equipment. Follow the correct sequence to power off, ensuring all parts are safely disengaged.

Following these steps will help maintain the longevity and reliability of your equipment while ensuring a smooth and efficient operation.

Maintenance and Troubleshooting Tips

Regular upkeep and prompt resolution of issues are essential to ensure the optimal performance and longevity of your equipment. This section provides guidelines on routine care and common problem-solving strategies to help you maintain your device in excellent working condition.

Routine Maintenance

Regular cleaning and inspection are crucial for reliable operation. Ensure that all components are free from debris and buildup. Check for any signs of wear or damage, especially in the key functional areas. Lubricate moving parts as recommended to prevent friction and ensure smooth operation. Keeping the fuel and air intake systems clean will also help maintain efficient performance.

Troubleshooting Common Issues

If you encounter problems, start by verifying that all connections are secure and that the necessary fluids are at appropriate levels. Should the device fail to start, check the ignition system and fuel supply first. Irregular output or sputtering could indicate clogs in the fuel or air pathways, which may require cleaning. For persistent issues, reviewing component conditions and replacing worn-out parts can often resolve the problem.

Common Issues and How to Fix Them

When operating a fogging device, users may encounter various challenges that can hinder its performance. Understanding these common problems and their solutions can help ensure smooth operation and optimal results. Below, we outline frequent issues and provide practical steps to resolve them.

| Issue | Description | Solution |

|---|---|---|

| Device Not Operating | The device fails to start or produce fog. | Check the power supply to ensure it is connected properly. Verify that the power switch is in the “on” position. If the device still does not operate, inspect the fuse and replace it if necessary. |

| Insufficient Fog Output | The amount of fog produced is less than expected. | Ensure the fog liquid is at an adequate level and properly filled. Clean the fogging nozzle and check for any blockages. Verify that the heating element is functioning correctly. |

| Uneven Fog Distribution | The fog is not dispersing evenly or is concentrated in certain areas. | Adjust the position of the device to ensure even coverage. Clean the nozzle to remove any obstructions that might affect the distribution. Check for any leaks or damage that could affect performance. |

| Unusual Noises | The device makes unusual sounds during operation. | Examine the device for loose components or debris. Tighten any loose screws and remove any foreign objects. If the noise persists, consult a professional technician for further inspection. |