Maintaining your outdoor spaces often involves the need for precise and effective grass trimming. This tool offers a streamlined solution for keeping your garden edges neat and tidy, ensuring a clean finish with minimal effort. The following sections provide an in-depth overview of how to make the most out of this essential gardening equipment, from setup to daily operation.

Whether you’re new to using such a device or looking to refine your technique, this guide covers all the necessary details. By understanding the correct procedures and safety measures, you can achieve optimal performance, extend the lifespan of your equipment, and enhance your overall gardening experience.

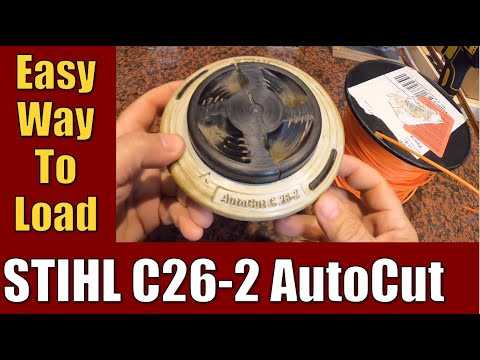

Overview of Stihl Autocut 25-2 Features

The model in question offers a range of functionalities designed to enhance efficiency and ease of use during trimming tasks. This section provides a comprehensive look at the key attributes that make this tool a reliable choice for users.

Key Attributes

- Simple loading mechanism: The system is engineered for quick and effortless line replacement, reducing downtime during use.

- Durable construction: Crafted with materials that withstand regular wear and tear, ensuring long-lasting performance.

- Precision cutting: Designed to deliver clean and accurate cuts, even in dense vegetation, providing professional results every time.

User-Friendly Design

- Ergonomic handling: The design includes features that promote comfort, allowing prolonged use without strain.

- Adjustable line length: The tool allows for easy adjustment of the line length, adapting to various trimming needs.

- Efficient operation: Optimized to perform with minimal effort, making it suitable for both beginners and experienced users.

Proper Techniques for Installing the Trimmer Head

Installing the cutting component on your grass-cutting tool requires careful attention to detail to ensure safety and optimal performance. The process involves several steps that, when followed correctly, will result in a securely attached and well-functioning part. Below is a step-by-step guide to assist in this task.

- Preparation: Begin by ensuring the tool is powered off and disconnected from any power source to avoid accidental operation. Place the tool on a stable surface.

- Remove the Existing Component: If a previous cutting element is attached, carefully remove it by unscrewing or detaching it as per the model’s design. Make sure to retain any screws or bolts for later use.

- Position the New Component: Align the new cutting part with the mounting point, ensuring that the central hole or attachment point is correctly aligned with the tool’s axis.

- Refilling and Replacing Trimmer Line

Maintaining your grass-cutting tool’s effectiveness requires periodic attention to the line used for trimming. Properly replacing or refilling the cutting line ensures consistent performance and helps avoid potential issues during operation. This section guides you through the essential steps needed to refresh the trimming line, emphasizing ease and efficiency.

Preparation

- Ensure the device is switched off and unplugged, if applicable, to prevent accidental activation.

- Locate the spool housing and prepare to access the trimming line by removing any covers or locking mechanisms.

Replacing the Trimmer Line

- Remove any remaining line from the spool. Inspect the spool and housing for any debris or wear, cleaning as necessary.

- Cut a new piece of line to the recommended length for your specific model.

- Feed the line into the designated holes or slots, ensuring it is evenly wound around the spool.

- Reassemble the spool housing, making sure the line ends are properly placed in the exit holes.

- Test the assembly by gently pulling on the line to confirm it feeds correctly.

Following these steps will ensure your tool is equipped with a fresh line, ready for the next task. Regular maintenance of the cutting line not only prolongs the life of your tool but also enhances its overall performance.

Maintaining and Cleaning Your Stihl Autocut 25-2

Regular upkeep and proper cleansing are essential for ensuring the longevity and optimal performance of your tool. By following a consistent routine, you can prevent wear and tear, reduce downtime, and enhance efficiency during use.

Maintenance Task Recommended Frequency Inspecting for debris and obstructions After every use Checking and replacing the cutting line As needed, based on wear Cleaning the housing and spool Monthly Lubricating moving parts Quarterly Begin by removing any visible debris

Troubleshooting Common Issues with the Trimmer

Maintaining the smooth operation of your trimmer requires understanding how to identify and resolve typical problems that may arise during use. By knowing the signs of common malfunctions and applying straightforward solutions, you can ensure your equipment continues to perform efficiently.

Difficulty in Line Advancement

One of the most frequent issues users encounter is trouble with the line not advancing correctly. This can often be attributed to incorrect installation of the cutting line or debris obstructing the spool. To address this, ensure the line is wound tightly and evenly, and inspect the spool for any blockages. Regular cleaning can prevent such obstructions from causing interruptions.

Excessive Vibration

Another issue that may occur is excessive vibration during operation. This can be caused by an unbalanced cutting head or worn components. To mitigate this, check that all parts are securely fastened and in good condition. Replacing worn-out parts as needed will help maintain smooth operation and reduce vibration.

Safety Guidelines for Effective Operation

Ensuring safe use of your cutting equipment involves adhering to fundamental safety practices that prevent accidents and enhance operational efficiency. Proper preparation and awareness of potential hazards are essential for maintaining a safe working environment.

1. Wear Appropriate Protective Gear: Always use recommended safety equipment such as gloves, eye protection, and hearing protection. This reduces the risk of injuries caused by debris or loud noise.

2. Inspect Equipment Regularly: Before use, check the equipment for any signs of damage or wear. Ensure that all components are securely fastened and functioning correctly to avoid malfunctions during operation.

3. Follow Operating Instructions: Familiarize yourself with the operational procedures and guidelines provided by the manufacturer. Adhering to these instructions ensures that you are using the equipment correctly and safely.

4. Maintain a Clear Work Area: Keep your workspace free of obstacles and clutter. A well-organized area helps in preventing accidents and allows for better maneuverability while operating the equipment.

5. Use Equipment as Intended: Avoid using the equipment for purposes other than those specified by the manufacturer. Misuse can lead to dangerous situations and damage to the equipment.

6. Stay Alert and Focused: Always be attentive while operating the equipment. Avoid distractions and remain focused on the task to ensure a safe and effective operation.