When working on creative sewing projects, unexpected technical problems can disrupt the flow and lead to frustration. To keep your stitching smooth and avoid unnecessary delays, it’s essential to know how to address frequent mechanical challenges. This section provides a detailed look into resolving these common complications effectively.

Whether you’re facing thread tangles, needle breaks, or uneven stitches, understanding the steps to troubleshoot and resolve these issues can save both time and effort. By mastering these solutions, you ensure that your sewing experience remains as seamless as possible.

With practical tips and clear guidance, this resource empowers you to maintain the efficiency and longevity of your machine. Addressing these routine obstacles with confidence will help you stay focused on bringing your creative visions to life.

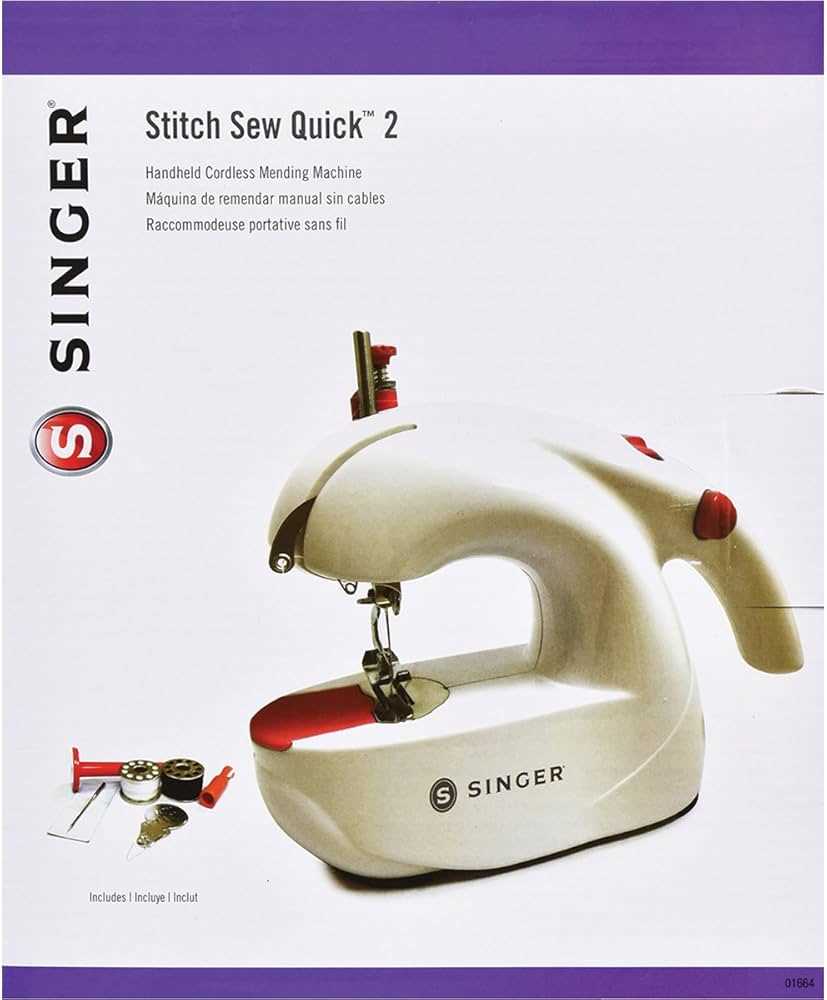

Overview of Singer Quick Fix Features

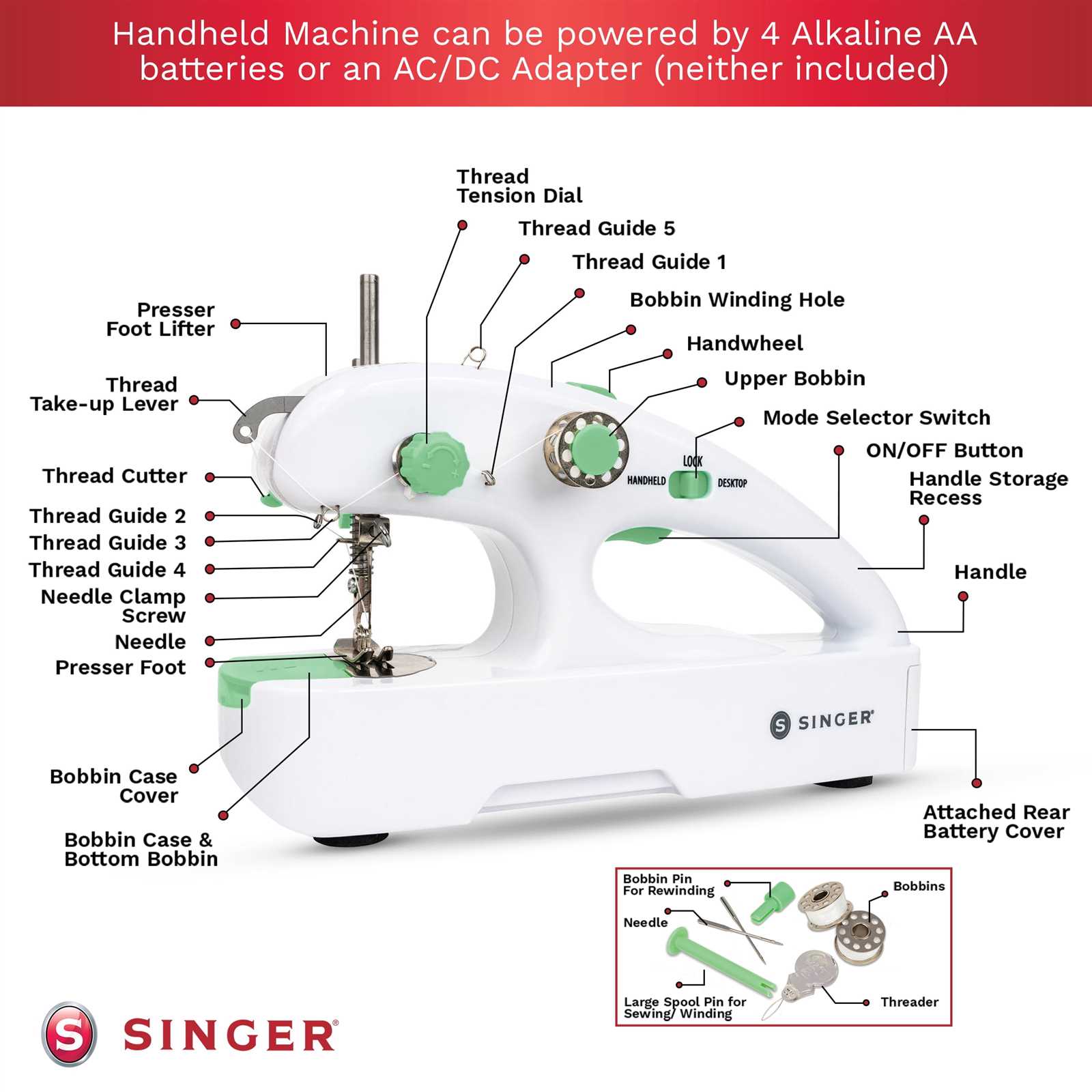

The device is a compact and efficient tool designed to assist users in handling various sewing tasks with ease. It provides a range of functions that make it a valuable addition to any sewing kit, offering convenience and versatility for both beginners and experienced users alike.

Key Functions

- Portability: The lightweight and compact design ensures easy transportation, making it suitable for use in various locations, whether at home or on the go.

- User-Friendly Operation: The intuitive interface and simple controls allow for quick setup and operation, reducing the learning curve for new users.

- Versatile Stitching Options: Multiple stitching capabilities provide the flexibility to handle different types of fabrics and sewing needs, from basic repairs to more intricate tasks.

- Battery-Powered: The ability to run on batteries enhances mobility, allowing for use without the need for a constant power source.

Additional Features

- Thread Management: Built-in mechanisms for easy threading and tension control ensure smooth and consistent stitches, minimizing the chance of errors.

- Accessory Compatibility: The tool is designed to work with a variety of standard sewing accessories, expanding its functionality and adaptability to different projects.

- Durability: Constructed with high-quality materials, the device offers reliable performance over time, even with frequent use.

Getting Started with Your Sewing Machine

Embarking on your journey with a sewing machine opens up a world of creativity and functionality. Before diving into your first project, it’s essential to become familiar with the basics. This section will guide you through the initial setup and key features, ensuring you have a solid foundation for your sewing endeavors.

Unpacking and Setting Up

Begin by carefully removing the machine from its packaging and placing it on a stable, flat surface. Ensure all components and accessories are accounted for, including the power cord, foot pedal, and any additional attachments.

- Place the machine on a sturdy table with ample lighting.

- Connect the power cord and foot pedal to their designated ports.

- Plug the machine into an electrical outlet, making sure it’s switched off at this point.

Familiarizing Yourself with the Machine

Understanding the basic parts of the machine is crucial. Spend some time exploring the different components to gain confidence in using them.

- Threading the Needle: Learn how to thread the needle properly by following the numbered guides on the machine. This ensures smooth operation and prevents issues during sewing.

- Winding the Bobbin: Familiarize yourself with the bobbin winder, and practice winding a bobbin with thread. Properly wound bobbins are key to achieving even stitches.

- Adjusting Tension: Experiment with the tension dial to understand how it affects stitch quality. Proper tension settings vary based on fabric and thread types.

Once you’re comfortable with these fundamental tasks, you’ll be ready to start experimenting with simple stitches and patterns. Taking the time to understand your machine will ensure a smoother and more enjoyable sewing experience.

Troubleshooting Common Sewing Issues

Even with the most reliable equipment, sewing projects can sometimes encounter challenges that interrupt your workflow. Understanding the root cause of these problems can help you resolve them efficiently and prevent future occurrences. Below, you’ll find solutions to some of the most frequent issues you might face while working on your projects.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Thread Breaking | Poor thread quality, improper threading, or tension too high | Use high-quality thread, rethread the machine correctly, adjust tension |

| Skipped Stitches | Blunt needle, wrong needle type, or fabric too thick | Replace the needle, use a needle suited for the fabric, slow down stitching |

| Fabric Puckering | Incorrect tension, wrong needle, or lightweight fabric | Adjust tension, use a smaller needle, stabilize the fabric |

| Machine Not Feeding Fabric | Feed dogs not raised, fabric too thick, or presser foot pressure too low | Raise feed dogs, use a walking foot, increase presser foot pressure |

| Bobbin Thread Tangling | Improper bobbin winding, incorrect insertion, or tension issues | Rewind bobbin evenly, insert bobbin correctly, adjust bobbin tension |

By identifying and addressing these common problems, you can maintain smooth and efficient sewing sessions, ensuring your projects are completed with minimal frustration.

Maintaining and Cleaning Your Machine

Regular upkeep and thorough cleaning are essential to ensure the longevity and optimal performance of your sewing device. By dedicating time to these tasks, you prevent issues that could affect its functionality, keeping your tool in excellent working condition.

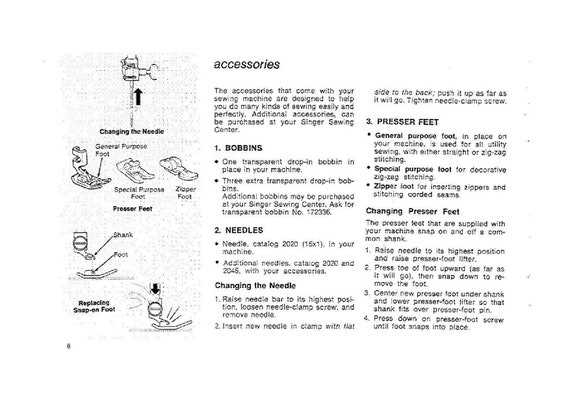

Basic Maintenance: Start by unplugging the machine to avoid any accidents. Remove the needle, presser foot, and thread from the device. These steps make it easier to access and clean various components. Inspect the area around the needle plate for any lint or fabric remnants. Use a small brush to gently sweep away any debris. Ensure that the feed dogs, bobbin case, and surrounding areas are free from dust.

Lubrication: Keeping the internal mechanisms properly lubricated is crucial. Check the manual for guidance on where to apply oil, focusing on moving parts that experience the most friction. Only use oil specifically designed for sewing tools, as other types may cause damage. Apply a few drops in the designated spots, being careful not to over-lubricate. Wipe away any excess to avoid attracting more lint and dust.

Cleaning the Bobbin Area: The bobbin area is prone to accumulating lint and thread bits, which can lead to jams or uneven stitching. Remove the bobbin and its case, then use a brush or a compressed air canister to clear out any debris. Ensure that the case is free of any obstructions before reassembling. This step helps maintain smooth operation and consistent stitch quality.

Checking Tension and Alignment: Periodically inspect the tension settings and alignment of your device. Misalignment or improper tension can lead to skipped stitches or thread breakage. Refer to your guide to ensure that all settings are correct and make adjustments as needed. This simple check can prevent many common issues and extend the life of your equipment.

Consistent care and cleaning are key to keeping your sewing machine running smoothly and efficiently. By following these maintenance steps, you ensure that your device remains reliable and performs at its best for years to come.

Essential Safety Tips for Beginners

Starting a new project or learning a new skill can be both exciting and challenging. It’s crucial to approach this process with a strong focus on safety to prevent accidents and ensure a smooth experience. This section aims to provide key advice for those who are just beginning their journey with their new equipment or technique, helping to build a foundation of safe practices.

Understand Your Equipment

Before diving into any hands-on work, take the time to familiarize yourself with your equipment. Read through the user guide thoroughly to understand its components, functions, and safety features. Proper knowledge of how your equipment operates is essential for minimizing risks and enhancing efficiency.

Follow Safety Protocols

Always adhere to recommended safety guidelines when using your equipment. Wear appropriate protective gear, such as gloves and goggles, to shield yourself from potential hazards. Additionally, keep your workspace clean and organized to avoid accidents. Consistent safety practices will not only protect you but also ensure that you achieve the best results from your work.

Advanced Techniques for Efficient Sewing

Mastering the art of sewing requires more than just basic skills. To truly excel, one must delve into advanced methods that enhance both precision and speed. This section will explore strategies designed to optimize sewing practices, ensuring that each project is completed with greater ease and professionalism.

Optimizing Your Workspace

A well-organized environment can significantly boost efficiency. Consider the following tips:

- Arrange tools and materials within easy reach to minimize movement.

- Invest in a cutting mat with clear measurements for accurate fabric cutting.

- Maintain a clutter-free workspace to reduce distractions and errors.

Enhancing Sewing Techniques

Improving your sewing techniques can lead to faster and more precise outcomes. Incorporate these advanced methods into your routine:

- Use specialty presser feet for specific tasks, such as zippers or piping.

- Implement chain piecing to sew multiple pieces of fabric in a continuous chain, reducing time spent starting and stopping.

- Employ pressing techniques, like using a seam roll or tailor’s ham, to achieve crisp and professional results.