Delving into the realm of timeless sewing machines, this section explores the intricate details and functionalities that have made these devices indispensable in various craft and industrial settings. By understanding the nuances of this remarkable model, users can enhance their fabric-working experience, ensuring precision and efficiency in every stitch.

This guide provides clear explanations and valuable insights into the operation and maintenance of this legendary machine. Whether you are an experienced tailor or a newcomer to the world of sewing, the following information will equip you with the knowledge needed to make the most of this powerful tool.

Explore the key features, learn essential techniques, and discover tips that will help you maintain the longevity and performance of your sewing equipment. With this information at hand, you will be well-prepared to tackle any sewing project with confidence and skill.

Sewing Machine Overview

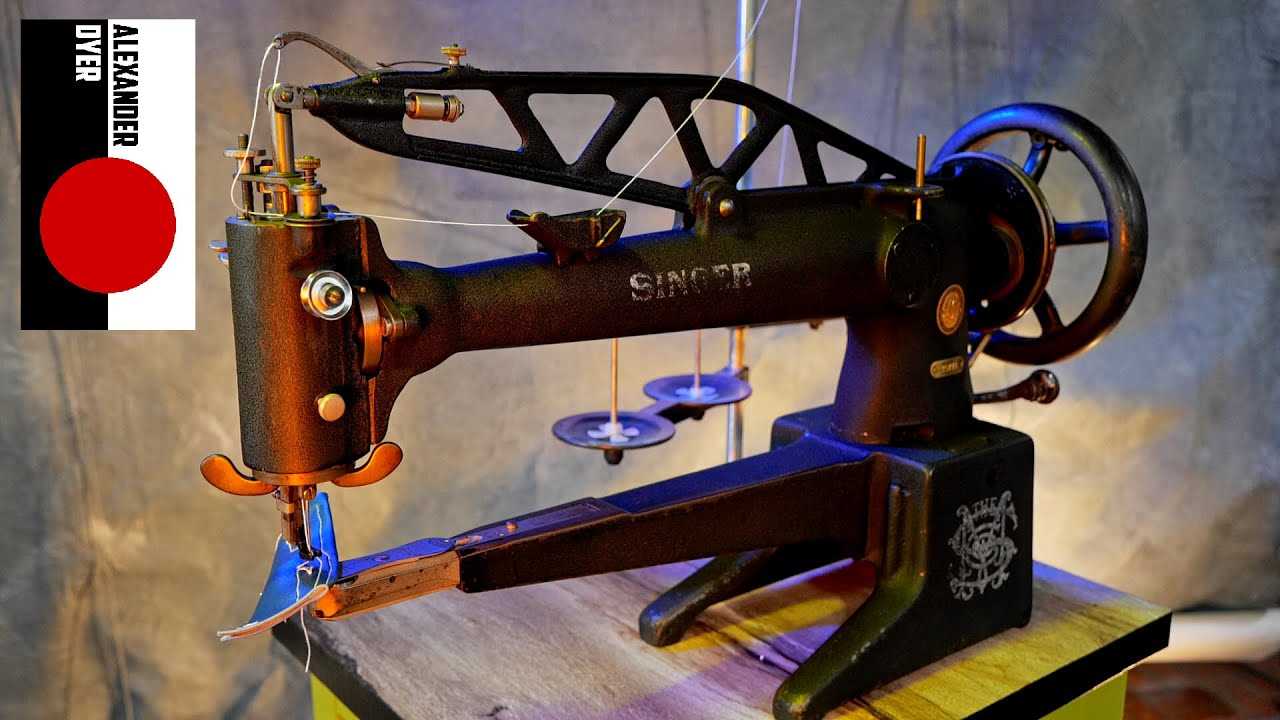

This section provides a detailed examination of a highly regarded, heavy-duty stitching device known for its precision and reliability. Designed for industrial use, this robust machine is an essential tool for those working with thick and durable materials. Its construction and features make it an excellent choice for professional tailors and craftsmen looking to handle demanding sewing tasks with ease.

Design and Build

Constructed with durability in mind, the unit boasts a sturdy frame and a powerful motor, capable of handling tough fabrics like leather and canvas. The machine’s design emphasizes stability and consistency, ensuring that every stitch is uniform, even when working at high speeds. Its user-friendly interface and adjustable settings allow for flexibility in various sewing projects.

Performance and Features

Equipped with advanced technology, this sewing apparatus delivers high-speed performance without compromising on accuracy. It includes features that cater to a wide range of sewing needs, from simple repairs to complex projects. The machine is engineered to operate smoothly under continuous use, making it a reliable partner in any professional workshop.

Key Features of the Heavy-Duty Industrial Sewing Machine

This robust machine is renowned for its outstanding capabilities, making it a preferred choice for professionals who require reliability and precision. The following sections highlight the main attributes that contribute to its efficiency and durability.

High-Speed Performance

Engineered for rapid operation, this sewing equipment delivers exceptional speed without compromising stitch quality. It is designed to handle heavy materials, allowing for consistent results even under intense use.

Versatile Stitching Options

Equipped with a variety of stitch types, this machinery offers flexibility in sewing, accommodating different fabrics and techniques. Its adaptability ensures that it can meet diverse project requirements.

| Feature | Description |

|---|---|

| Maximum Stitch Length | Adjustable to meet different project needs, providing control over the final outcome. |

| Durable Construction | Built with robust materials to withstand prolonged use, ensuring long-lasting performance. |

| Heavy Material Compatibility | Capable of sewing through thick and tough fabrics with ease, making it suitable for a wide range of applications. |

Threading and Setup Instructions

Proper preparation and alignment are essential for achieving optimal performance from your device. This section will guide you through the necessary steps to ensure that the machine is ready for efficient operation. Follow these directions carefully to avoid any issues during use.

Threading the Needle

- Begin by raising the presser foot to release the tension discs.

- Guide the thread through the designated path, making sure it passes through all the necessary guides and tension mechanisms.

- Insert the thread into the eye of the needle, ensuring it is pulled through with no slack.

Setting Up the Bobbin

- Place the bobbin in its designated holder, ensuring it rotates in the correct direction.

- Guide the thread through the bobbin case tension spring, ensuring a smooth and even pull.

- Insert the bobbin case into the machine, making sure it locks securely in place.

Once threading and setup are complete, you can proceed to test the stitch quality and make any necessary adjustments for optimal performance.

Troubleshooting Common Issues

When working with sewing machines, users may occasionally encounter challenges that disrupt smooth operation. Understanding the root causes of these issues is essential for maintaining optimal performance. In this section, we will explore typical problems that may arise during use and provide practical solutions to address them.

Thread Breakage: Frequent thread breakage can stem from various factors, such as incorrect threading, inappropriate tension settings, or poor-quality thread. Ensure that the machine is threaded correctly, check the tension, and use a high-quality thread suitable for your fabric.

Skipped Stitches: Skipped stitches often occur due to a bent needle, improper needle size, or incorrect fabric type. Replacing the needle, selecting the appropriate size, and using the right needle for the fabric can effectively resolve this issue.

Irregular Stitches: Uneven stitching may result from inconsistent tension, incorrect bobbin placement, or worn-out parts. Adjust the tension settings, ensure the bobbin is correctly positioned, and inspect the machine for any parts that may need replacement.

Machine Jamming: If the machine jams, it could be due to thread buildup in the bobbin area, debris in the mechanism, or improper needle installation. Regularly clean the machine, remove any thread buildup, and verify that the needle is correctly installed.

By addressing these common problems promptly, users can maintain efficient and reliable performance, ensuring a smooth and enjoyable sewing experience.

Maintenance and Care Tips

Regular upkeep of your equipment ensures long-lasting performance and optimal results. Proper attention to its maintenance will minimize the risk of malfunctions and extend its life span. Consistent care not only prevents common issues but also enhances efficiency.

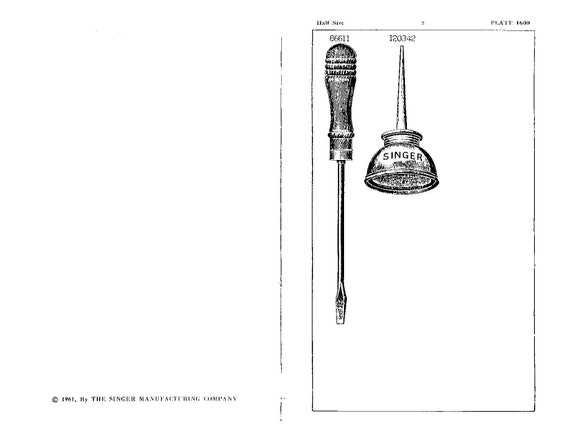

Cleaning: Regular cleaning is essential to keep all components functioning smoothly. Dust and debris can accumulate, causing wear and tear, so it’s important to keep the machine clean after each use. Use a soft brush or compressed air to remove any particles from hard-to-reach areas.

Lubrication: Applying the appropriate lubricant to moving parts reduces friction and prevents wear. Make sure to use the recommended lubricant for your device, and apply it sparingly to avoid buildup that could interfere with operation.

Inspection: Periodically check for signs of wear, loose screws, or other issues. Early detection of potential problems allows for timely repairs, preventing more serious damage. Regular inspections ensure that your equipment remains in peak condition.

Storage: When not in use, store your equipment in a dry, dust-free environment. Proper storage helps protect it from environmental factors that can cause damage over time, such as humidity or extreme temperatures.

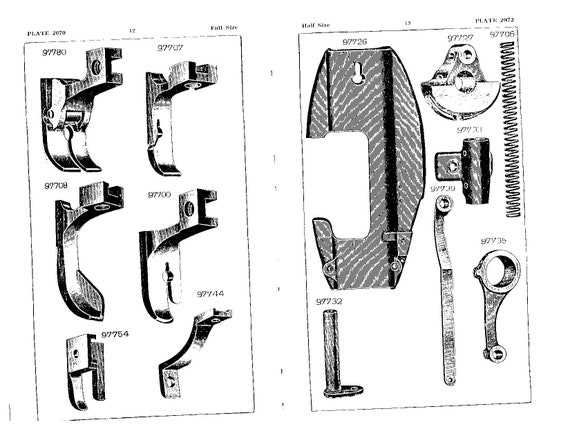

Where to Find Replacement Parts

When searching for spare components for your sewing machine, there are several reliable avenues to explore. It is crucial to identify trusted sources to ensure the quality and compatibility of the parts. Here are some effective ways to locate the necessary replacements.

Authorized Dealers and Retailers

Authorized dealers and retailers often provide genuine components and accessories for sewing machines. They have access to manufacturer-approved parts, ensuring that you receive high-quality and compatible items. Checking with these official outlets is a good first step.

Online Marketplaces and Specialty Stores

Online marketplaces and specialty stores offer a wide range of replacement parts. Websites dedicated to sewing machine supplies frequently stock various components and can be a valuable resource. Make sure to verify the reputation of the seller and the compatibility of the parts before making a purchase.