When it comes to mastering your new equipment, understanding its proper use and maintenance is crucial for achieving optimal performance. This guide is designed to offer comprehensive insights and practical advice for getting the most out of your latest acquisition. Whether you’re a seasoned professional or a newcomer, having clear instructions at your fingertips can make a significant difference in your work efficiency and overall satisfaction.

In this section, we delve into the key aspects of operating and caring for your new device. You’ll find detailed explanations on how to assemble, adjust, and troubleshoot your tool, ensuring that you can use it with confidence and ease. With step-by-step guidance and useful tips, this resource is tailored to help you navigate through every stage of using and maintaining your equipment.

By following the outlined procedures and recommendations, you’ll be equipped to handle any challenges that may arise and fully utilize the capabilities of your new tool. This guide aims to enhance your proficiency and extend the longevity of your equipment, providing you with a reliable companion for all your tasks.

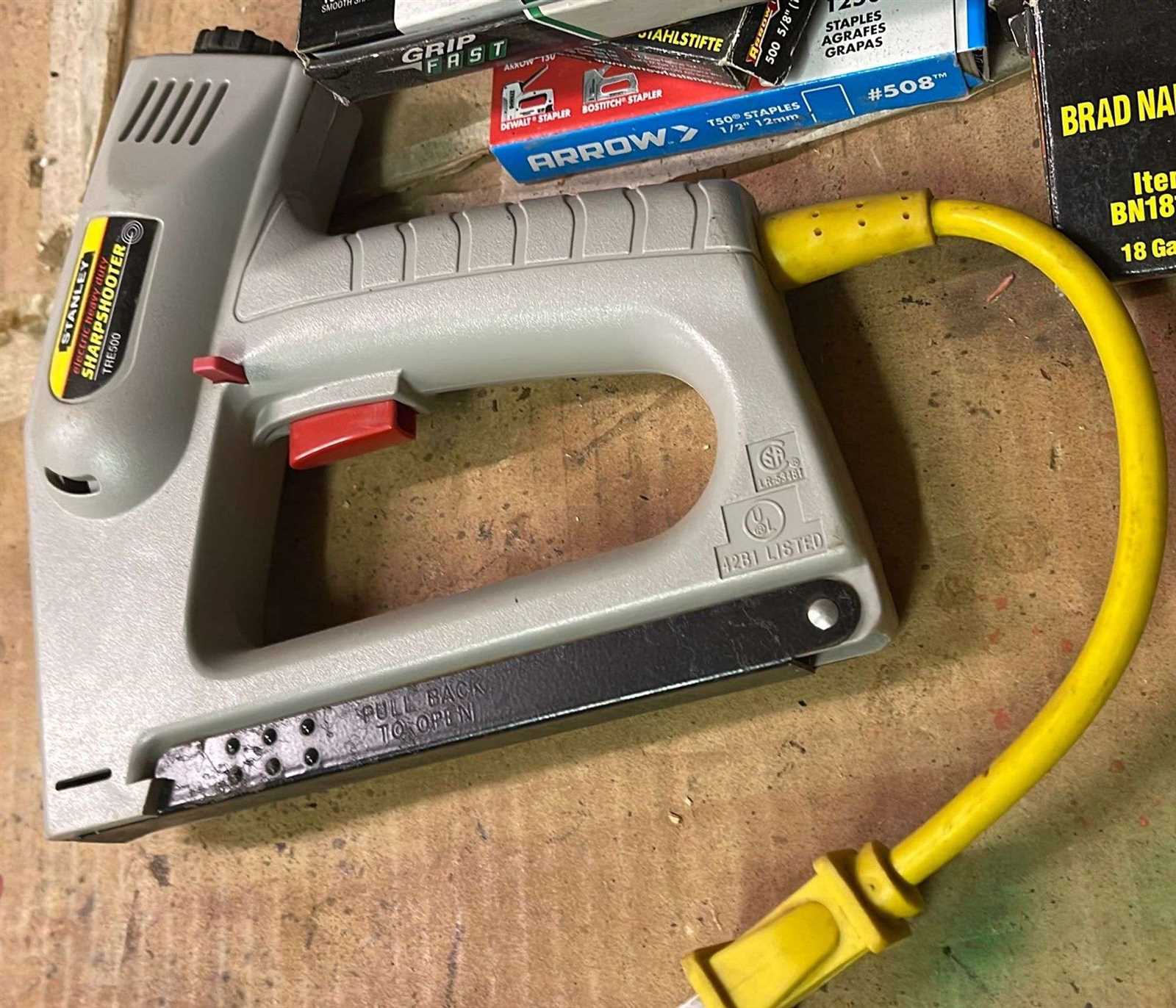

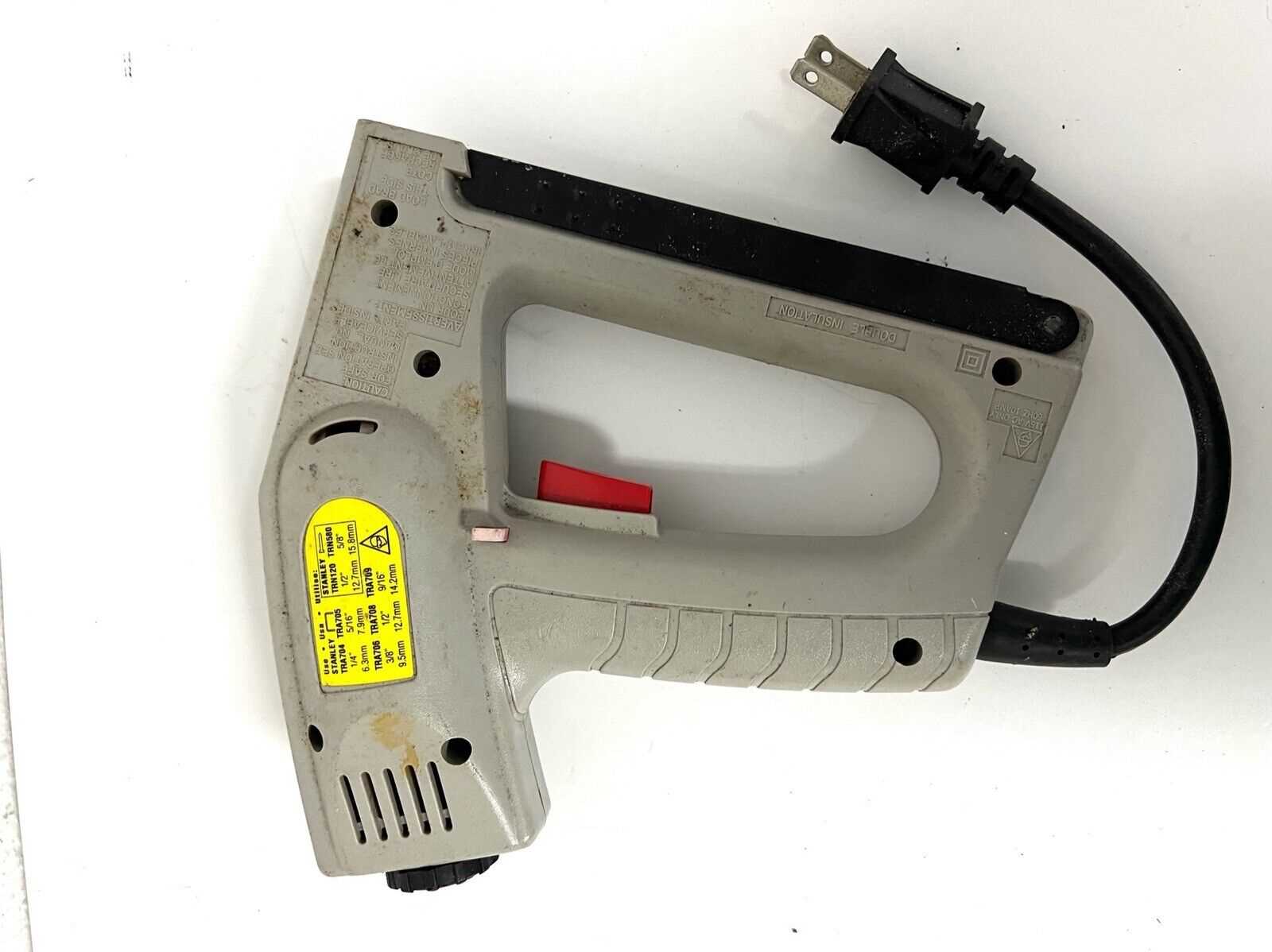

Overview of the Stanley Sharpshooter TRE500

This section provides a comprehensive examination of a highly regarded tool designed for precision fastening tasks. Renowned for its efficiency and reliability, this device is a favorite among both professionals and DIY enthusiasts. Its features are tailored to enhance performance in various applications, making it a versatile addition to any toolkit.

With an emphasis on user comfort and operational ease, this tool boasts an ergonomic design and intuitive controls. Its robust build ensures durability and consistent results, even under demanding conditions. Users can expect streamlined functionality that simplifies the fastening process, whether handling small-scale projects or more extensive tasks.

The tool’s advanced mechanisms contribute to its effectiveness, allowing for quick adjustments and minimal downtime. Its adaptability to different materials and fasteners underscores its practical value, offering both precision and power. Overall, this tool stands out as a reliable choice for anyone seeking to achieve high-quality results efficiently.

Key Features and Specifications

This section highlights the essential attributes and technical details of the device. It provides an overview of its capabilities, ensuring users understand the core functions and performance metrics. The following points outline the prominent characteristics and specifications, giving insight into the tool’s efficiency and usability.

Core Attributes

The device is equipped with advanced features designed to enhance precision and reliability. It boasts a powerful mechanism that ensures optimal performance in various tasks. With a focus on user-friendliness, it incorporates ergonomic design elements for ease of handling and operation. The inclusion of multiple settings allows for versatile use, adapting to different requirements and materials.

Technical Specifications

The specifications include a robust build quality, suitable for both professional and home use. Key metrics such as power output, operational capacity, and construction materials are detailed to provide a comprehensive understanding of the tool’s capabilities. Users can expect high durability and efficiency, making it a valuable addition to any toolkit.

Step-by-Step Operating Instructions

This section provides a comprehensive guide for utilizing the device effectively. It is designed to assist users in understanding each stage of operation, ensuring proper use and achieving optimal results. Follow these detailed steps to master the process with ease and precision.

- Preparation:

- Ensure that the tool is placed on a stable surface.

- Check that all components are securely attached.

- Verify that the power source is properly connected, if applicable.

- Loading:

- Carefully insert the required materials according to the specifications.

- Make sure that the materials are aligned correctly and securely positioned.

- Confirm that any safety locks or mechanisms are disengaged before proceeding.

- Operation:

- Activate the device using the designated controls or switches.

- Monitor the performance to ensure that the tool is functioning as expected.

- Make adjustments as needed to maintain efficiency and accuracy.

- Post-Operation:

- Turn off and disconnect the device from the power source, if necessary.

- Carefully remove any remaining materials or components.

- Clean and store the tool according to the guidelines provided.

By following these systematic procedures, users can achieve effective operation and maintain the longevity of the device. Each step is crucial for ensuring safety and optimal performance throughout its use.

Maintenance and Care Guidelines

Proper upkeep of your equipment ensures its longevity and optimal performance. Regular maintenance is essential to avoid potential issues and to maintain the device in peak condition. This section provides fundamental practices for keeping your tool in excellent working order.

1. Cleaning: Regularly clean the exterior and components of your device to remove any dust, debris, or residue. Use a soft cloth and mild cleaning solution to avoid damaging sensitive parts. Ensure that all openings and vents are free from blockages that could impair functionality.

2. Inspection: Periodically examine the tool for signs of wear or damage. Check all moving parts and fasteners to ensure they are secure and functioning correctly. If any parts appear worn or damaged, replace them promptly to prevent further issues.

3. Lubrication: Apply appropriate lubricants to moving parts as specified by the manufacturer. This will help to reduce friction and prevent premature wear. Be sure not to over-lubricate, as excess lubricant can attract dust and grime.

4. Storage: Store your equipment in a dry, clean environment to avoid exposure to moisture and extreme temperatures. Use a protective cover if available to shield it from dust and potential damage when not in use.

5. Usage: Follow the recommended usage guidelines to avoid overworking the tool. Adhere to the suggested operational limits to prevent undue stress on the device. Proper handling and usage will extend the life of your equipment.

Troubleshooting Common Issues

Encountering difficulties with your device can be frustrating, but many problems can be resolved with a few simple steps. This section is designed to help you identify and fix typical issues you might face. By following these troubleshooting tips, you can often address problems without the need for professional assistance.

- Device Not Powering On:

- Ensure the device is properly connected to a power source.

- Check if the power switch is turned on.

- Inspect the power cord for any damage or loose connections.

- Inconsistent Performance:

- Verify that the device is set up correctly according to the setup instructions.

- Examine the device for any obstructions or blockages that may affect performance.

- Ensure that all components are securely attached and functioning properly.

- Unusual Noises:

- Check if there are any foreign objects lodged in the device that might be causing noise.

- Inspect moving parts for wear and tear or any signs of damage.

- Consult the manufacturer’s guidelines for maintenance and cleaning instructions.

- Device Overheating:

- Ensure the device is placed in a well-ventilated area to prevent overheating.

- Check for dust buildup in vents or fans and clean if necessary.

- Monitor the device’s usage time and allow it to cool down periodically.

If these steps do not resolve the issue, it may be necessary to seek further assistance from a professional technician or contact customer support for additional help.

Safety Precautions and Tips

Ensuring safety while using power tools is essential for preventing accidents and ensuring effective operation. Adhering to proper safety practices not only protects the user but also enhances the longevity and performance of the tool. Below are key recommendations for maintaining a safe working environment.

1. Wear Appropriate Personal Protective Equipment (PPE): Always don safety goggles, gloves, and a dust mask when operating the tool. This gear helps protect against flying debris, sharp edges, and harmful dust particles.

2. Read the User Guide: Familiarize yourself with the equipment by thoroughly reading the user guide before use. Understanding the features, controls, and maintenance procedures will contribute to safer and more efficient operation.

3. Inspect the Tool Regularly: Before each use, inspect the tool for any damage or wear. Ensure that all parts are secure and functioning correctly. Replace or repair any faulty components promptly.

4. Keep the Work Area Clean: Maintain a clutter-free work environment to prevent tripping hazards and accidental tool contact. Ensure the area is well-lit and free of any obstacles that could impede your work.

5. Use the Tool Correctly: Operate the tool according to its intended purpose and avoid any misuse. Ensure that you have a firm grip and stable stance while working to prevent loss of control.

6. Unplug the Tool When Not in Use: Always disconnect the tool from the power source when not in use or when performing maintenance. This prevents accidental activation and ensures safety during handling.

7. Keep Children and Pets Away: Ensure that children and pets are kept at a safe distance from the work area. This minimizes the risk of accidental injury or interference with your work.

8. Avoid Distractions: Stay focused on the task at hand and avoid any distractions that could compromise your safety. Concentration is key to effective and safe tool use.

By following these safety precautions, you can ensure a safer working environment and extend the life of your tool. Always prioritize safety to achieve optimal performance and avoid unnecessary risks.