Proper upkeep of your equipment is crucial to ensuring its longevity and effectiveness. This section will guide you through the essential steps to maintain your tools in optimal working condition. By following these instructions, you can achieve consistent performance and extend the lifespan of your gear.

Whether you are a seasoned professional or a DIY enthusiast, understanding the nuances of equipment maintenance is key. In this guide, you will learn the best practices for keeping your tools sharp and ready for use. From setup to regular upkeep, every aspect will be covered in detail, ensuring you are well-prepared to handle any task efficiently.

The methods outlined here are designed to be user-friendly and accessible, making it easy for anyone to follow. You will find clear, concise directions that emphasize safety and precision. This guide is your go-to resource for keeping your tools in top shape, ensuring they remain reliable and effective for years to come.

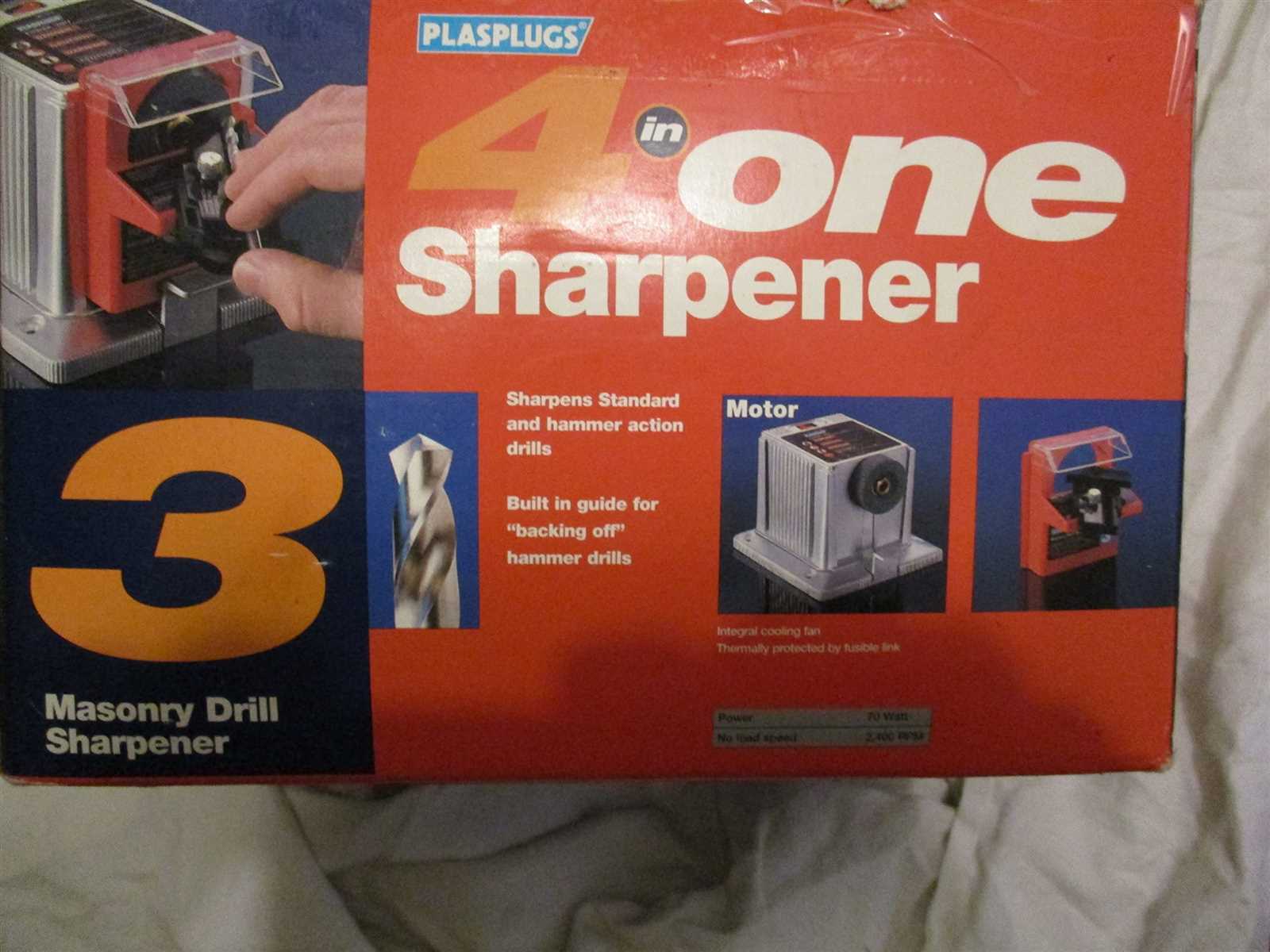

Understanding Your Drill Bit Sharpener

Proper maintenance of your tools ensures their longevity and optimal performance. This guide will help you grasp the essential aspects of using your tool sharpener, focusing on the key components and functions. By mastering these, you’ll achieve precise results every time.

Key Components Overview

Before you start, familiarize yourself with the different parts of the sharpening device. Each element plays a crucial role in the process, contributing to the efficiency and accuracy of the task.

| Component | Function |

|---|---|

| Guiding Mechanism | Ensures the tool maintains the correct angle during the sharpening process. |

| Abrasive Surface | Responsible for restoring the cutting edge by removing material in a controlled manner. |

| Adjustment Knob | Allows you to fine-tune the sharpening angle and depth for various tasks. |

Optimizing the Process

Achieving the best results requires an understanding of how to align your tool and maintain consistent pressure throughout the process. Proper alignment ensures uniform sharpening, extending the life and functionality of your equipment.

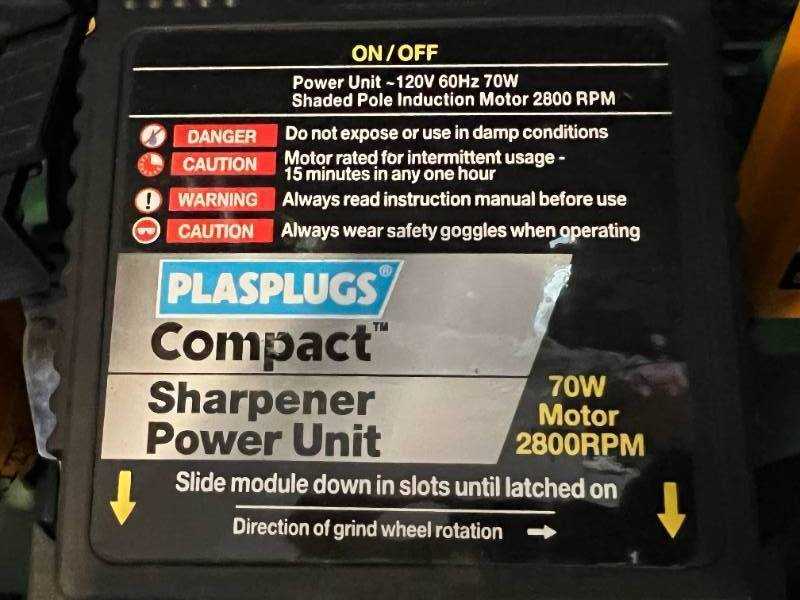

Setting Up the Device for First Use

Before you can begin using the equipment, it is essential to ensure that it is properly assembled and configured. This section will guide you through the initial setup process, ensuring that the unit is securely placed and ready for its intended function.

Unpacking and Inspecting

Carefully remove the device from its packaging and inspect it for any visible damage. Ensure that all components are present and in good condition. Refer to the list below to verify that you have all the necessary parts:

| Component | Description |

|---|---|

| Base Unit | The main body of the equipment |

| Support Bracket | A stabilizing piece to ensure proper alignment during use |

| Adjustment Knobs | Controls for fine-tuning the settings |

| Power Cord | Used to connect the device to a power source |

Basic Assembly

Begin by attaching the support bracket to the base unit, ensuring it is securely fastened. Next, connect the power cord to the designated port on the device, and plug it into a suitable power outlet. Adjust the knobs to set the device to its default settings, which are ideal for most initial operations. Ensure all parts are properly aligned before proceeding to power on the unit.

Key Features and How to Utilize Them

In this section, we’ll explore the essential characteristics of the device and the most effective methods to make the best use of these functionalities. The tool offers a range of features designed to improve efficiency and ease of use, making it a valuable addition to any workshop.

- Precision Control: The unit allows for precise adjustments, ensuring that you achieve the exact specifications needed for your task. This feature is especially useful for maintaining accuracy in your work.

- Ease of Use: The intuitive design of the device ensures that even beginners can quickly become proficient. Clear guides and ergonomic controls simplify the operation, reducing the learning curve.

- Durability: Built with high-quality materials, the tool is designed to withstand frequent use, offering long-lasting performance without compromising on functionality.

- Versatility: Adaptable to various tasks, the device can handle different sizes and types of materials, making it a versatile solution for diverse applications.

- Safety Features: Integrated safety mechanisms protect the user during operation, reducing the risk of accidents and ensuring a secure working environment.

To maximize the benefits of these features, it is essential to familiarize yourself with the settings and controls. Regular maintenance and proper handling will also contribute to the longevity and effectiveness of the tool. By understanding and utilizing these key characteristics, you can enhance your productivity and achieve professional results with ease.

Maintenance Tips to Ensure Longevity

Proper care and regular upkeep are essential to maintain the functionality and extend the life of your equipment. Consistent attention to these aspects can prevent common wear and tear, ensuring that your tool continues to operate at its peak performance.

Regular Cleaning

To keep your device in optimal condition, make sure to remove any dust, debris, or residue after each use. A clean surface prevents unnecessary strain and allows the components to function smoothly. Using a soft brush or cloth can help in reaching tight spots without causing damage.

Inspection and Lubrication

Periodically inspect your tool for signs of wear or loose parts. Tighten any screws and check for any cracks or damage. Applying a small amount of lubrication to moving parts can reduce friction, prevent rust, and extend the lifespan of the mechanism. Ensure that only suitable lubricants are used to avoid compromising the materials.

Storage Practices

When not in use, store the equipment in a dry, cool place to protect it from moisture and temperature fluctuations, which can cause deterioration. Keeping it in a dedicated case or protective cover can also prevent accidental damage.

Troubleshooting Common Issues

When dealing with any equipment, occasional challenges may arise. This section will guide you through identifying and resolving some of the most frequent problems that can occur during regular use. Addressing these issues promptly can ensure smooth operation and extend the lifespan of your tool.

| Problem | Possible Cause | Solution |

|---|---|---|

| Device not powering on | Power source not connected or malfunctioning | Check the power connection and ensure the outlet is functioning properly. If using batteries, verify they are correctly installed and charged. |

| Unusual noise during operation | Component misalignment or debris inside | Turn off the equipment and inspect for any obstructions or parts that may be out of place. Clean the internal parts and reassemble carefully. |

| Performance not meeting expectations | Worn or damaged components | Inspect the moving parts for wear and tear. Replace any damaged or excessively worn pieces to restore optimal functionality. |

| Inconsistent results | Improper setup or technique | Review the setup process and ensure all settings are correctly adjusted. Practice consistent techniques to achieve uniform outcomes. |

Enhancing Performance Through Proper Sharpening

Maintaining optimal performance for your tools is crucial for ensuring their effectiveness and longevity. Proper edge honing not only improves cutting efficiency but also extends the lifespan of the equipment. By following appropriate techniques for edge refinement, you can achieve better results and enhance overall productivity.

Here are key benefits of correctly honing your tools:

- Increased Efficiency: A well-maintained edge allows for smoother operation, reducing the effort required and improving the quality of work.

- Extended Tool Life: Regular and proper maintenance prevents premature wear and tear, ensuring that tools remain effective for a longer period.

- Reduced Downtime: Well-maintained tools require less frequent replacements or repairs, leading to fewer interruptions in your workflow.

- Cost Savings: Investing in proper maintenance minimizes the need for replacements and repairs, resulting in significant cost savings over time.

To achieve these benefits, follow these best practices for edge refinement:

- Regular Maintenance: Perform regular checks and sharpening sessions to keep the edges in optimal condition.

- Proper Technique: Use the correct methods and tools for honing to ensure effective results and prevent damage.

- Consistent Angle: Maintain a consistent angle while honing to achieve uniform sharpness and performance.

- Clean and Inspect: After honing, clean the tools thoroughly and inspect for any signs of wear or damage.

By adhering to these guidelines, you can significantly enhance the performance and durability of your tools, ensuring they continue to serve you effectively in all tasks.