Modern electrical systems require robust solutions to ensure safety, reliability, and efficient operation. The evolving landscape of power distribution and management emphasizes the need for devices that can swiftly respond to various faults and anomalies, safeguarding infrastructure and minimizing downtime. This guide delves into the advanced functionalities and configurations of protective equipment designed to meet these challenges.

Understanding the complexities of power system protection is crucial for both seasoned professionals and newcomers in the field. In this document, you will find a thorough exploration of sophisticated protective devices, highlighting their features, settings, and operational protocols. Whether you are installing new equipment, conducting maintenance, or optimizing existing setups, the information provided here will be an invaluable resource.

Step-by-step instructions are provided to help you navigate through different processes, from initial setup to troubleshooting common issues. The aim is to equip you with the knowledge and skills necessary to make informed decisions, ensuring the protection devices operate optimally under various conditions. Each section is carefully structured to facilitate a clear understanding of the topics, making it easier to apply this knowledge in real-world scenarios.

Overview of SEL-400 Series Relays

The devices in this lineup offer advanced capabilities for safeguarding and controlling electrical power systems. Designed to meet the needs of modern power distribution, these devices provide a wide range of features to ensure reliability and efficiency in both industrial and utility settings. By leveraging cutting-edge technology, they enhance operational performance and protect against faults and abnormal conditions.

Key Features

These devices are equipped with a variety of functions that cater to different protection and control requirements. High-speed protection and accurate fault detection are core benefits, allowing for rapid response to electrical disturbances. Additionally, they support multiple communication protocols, making them highly adaptable to various network configurations.

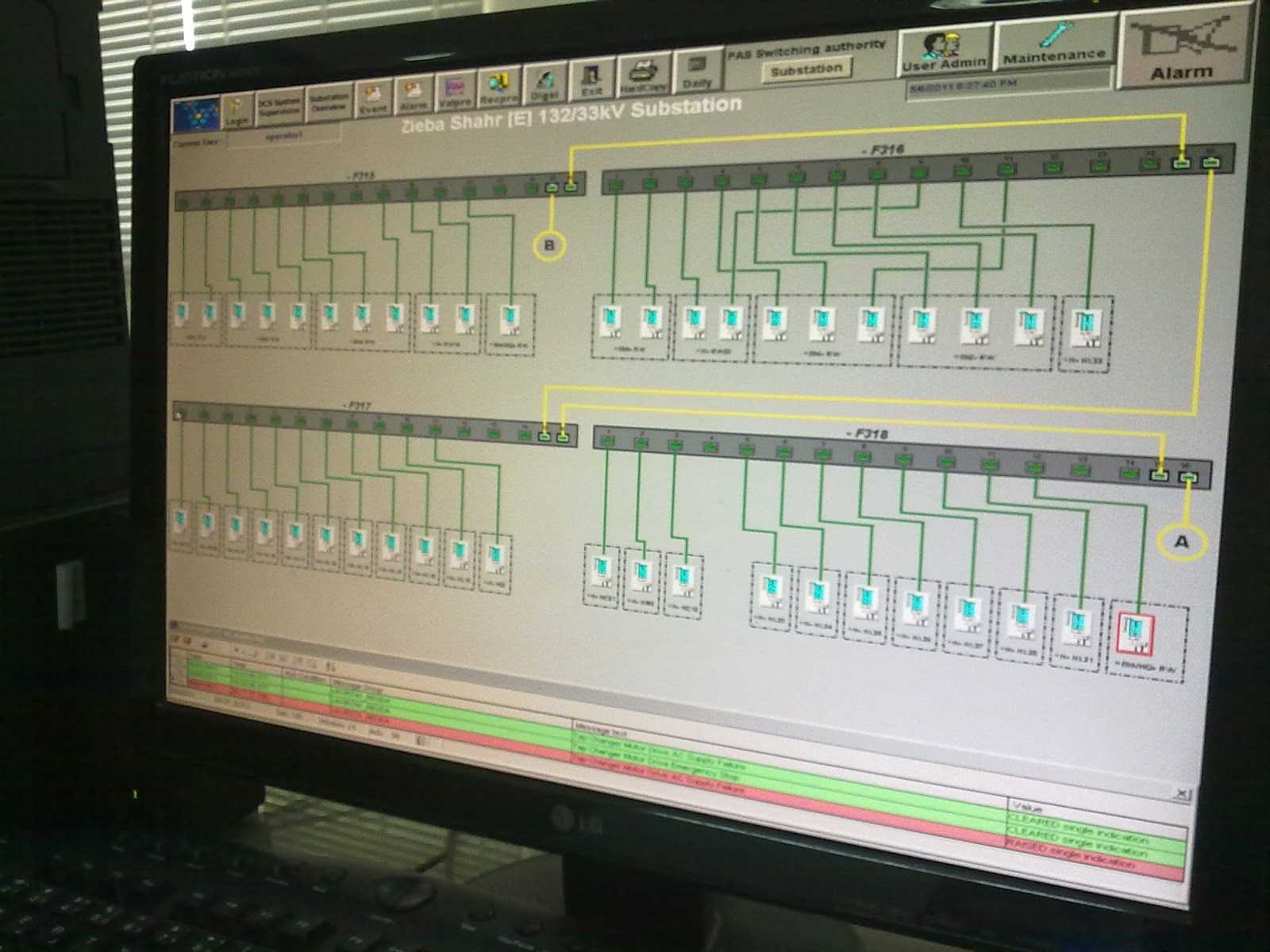

Applications

Applicable in a range of environments, these devices are suitable for both primary and secondary protection schemes. Their versatile nature allows them to be used in settings such as substations, industrial plants, and renewable energy facilities. The integration of advanced diagnostics and monitoring tools further aids in maintaining system integrity and minimizing downtime.

Key Features and Benefits

Understanding the main functionalities and advantages of this product is crucial for optimizing its usage and ensuring reliable operation. This section provides an overview of the essential attributes and the benefits they offer, highlighting how they contribute to overall efficiency, safety, and ease of use.

Advanced Protection Mechanisms

One of the most notable features is the implementation of advanced protection mechanisms. These are designed to detect faults quickly and accurately, minimizing the risk of damage to equipment and ensuring the continuity of operations. With precise fault identification, users can respond promptly to any issues, reducing downtime and maintaining system stability.

Flexible Configuration and Integration

The product also offers a high level of flexibility in configuration and integration, allowing it to adapt to various operational environments and requirements. It supports multiple communication protocols, making it compatible with different systems and enhancing its versatility. This adaptability ensures that the product can be easily integrated into existing setups, providing a seamless experience for users.

In summary, the combination of robust protection capabilities and flexible integration options makes this product an ideal choice for enhancing system reliability and performance. By leveraging these features, users can achieve greater operational efficiency and ensure long-term stability in their applications.

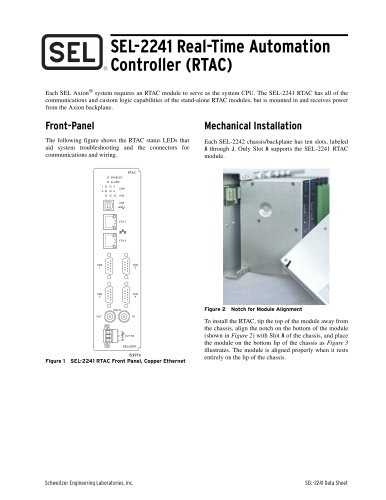

Installation Process for SEL-400 Relays

The following guide provides a comprehensive overview of the steps required to properly set up and configure the electrical protection devices. It is crucial to follow these guidelines to ensure a safe and efficient installation that meets all technical specifications and operational requirements. This section covers the entire process, from initial preparation to final testing, to guarantee optimal performance and reliability.

Before beginning the installation, ensure all necessary tools and equipment are available and that you have reviewed the relevant safety protocols. Familiarize yourself with the installation environment to avoid any potential hazards or obstacles that could impede the process.

The installation involves several key stages: mounting the device, connecting the wiring, configuring settings, and performing operational checks. The following table outlines the basic steps required for a successful installation:

| Step | Description |

|---|---|

| 1. Preparation | Gather all required tools and review safety guidelines. Ensure the installation site is prepared and free of any obstructions. |

| 2. Mounting | Secure the device to the designated panel or enclosure using appropriate hardware. Verify that the unit is firmly in place. |

| 3. Wiring | Connect the power and communication cables according to the wiring diagram. Double-check all connections for accuracy. |

| 4. Configuration | Use the control panel to set up initial parameters and settings. Adjust configurations as needed to match the specific application. |

| 5. Testing | Perform functional tests to ensure the device operates as expected. Verify all settings and connections before finalizing the installation. |

Upon completing these steps, recheck all components and connections to confirm that the installation is secure and functional. Any discrepancies should be addressed immediately to prevent potential issues during operation.

Mounting and Wiring Guidelines

Proper installation and wiring are crucial for ensuring optimal performance and longevity of electrical devices. This section provides essential guidelines for securely mounting and accurately wiring your equipment to prevent issues related to improper handling. Following these instructions will help maintain the integrity and functionality of your system.

Mounting Recommendations:

When choosing a location for installation, select a stable, vibration-free environment to avoid mechanical stress on the device. Ensure there is adequate space around the equipment for ventilation and easy access for maintenance. Use mounting brackets or screws compatible with the unit to securely fasten it to the surface, following the manufacturer’s specified torque settings to avoid damage.

Wiring Considerations:

Carefully plan the wiring layout to minimize electromagnetic interference and reduce the risk of short circuits. Use appropriate wire gauges that match the current and voltage requirements of the system. Secure all connections using terminals or connectors recommended for the application, and double-check all wiring against the schematic diagram before powering the system.

| Step | Description |

|---|---|

| 1 | Select an appropriate mounting location, ensuring it is free from excessive vibration and environmental hazards. |

| 2 | Secure the device using compatible mounting hardware, adhering to specified torque settings. |

| 3 | Plan the wiring layout to minimize interference and follow safety standards. |

| 4 | Use correct wire gauges and secure connections as per guidelines. |

| 5 | Double-check all wiring against diagrams before powering up the device. |

Configuration of Protection Settings

Proper configuration of protection settings is crucial for ensuring the reliability and safety of electrical systems. This process involves carefully selecting and adjusting parameters to detect and isolate faults, preventing damage to equipment and minimizing downtime. Understanding the appropriate settings and how to implement them can greatly enhance the overall performance of a power system.

Setting Up Overcurrent Protection

Overcurrent protection settings must be configured to safeguard equipment from excessive currents that may result from faults or abnormal conditions. Key parameters include pickup current, which determines the level at which the protection activates, and time delay, which defines how long the device waits before responding. Adjusting these parameters appropriately ensures that the protection system operates effectively without causing unnecessary interruptions.

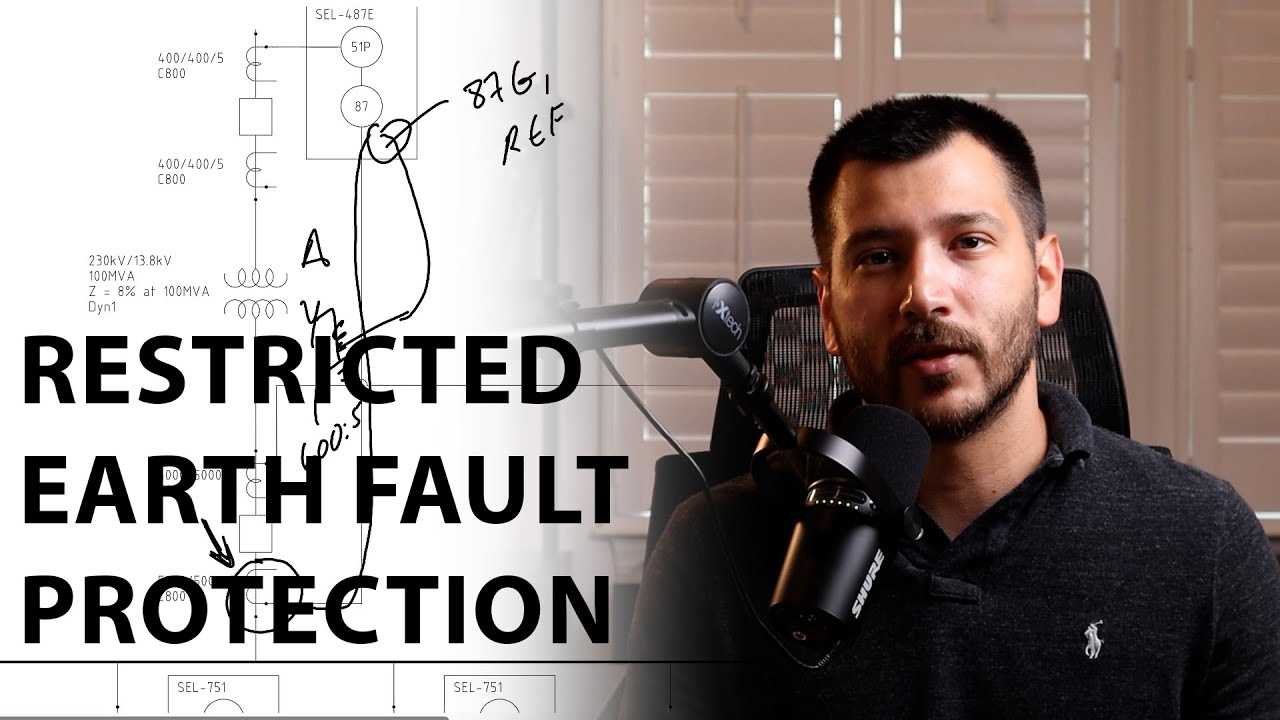

Configuring Differential Protection

Differential protection settings are designed to detect discrepancies between incoming and outgoing currents within a protected zone. This method is highly effective for identifying faults that might otherwise go unnoticed. Key settings to configure include restraint current, which helps differentiate between fault conditions and normal operating conditions, and trip settings, which determine the threshold for initiating a disconnection. Fine-tuning these values is essential to maintain the balance between sensitivity and security in the protection system.

By carefully configuring these and other protection settings, operators can enhance the safety and efficiency of electrical systems, reducing the risk of equipment failure and ensuring continuous operation.

Using Software Tools Effectively

Maximizing the efficiency of software tools is crucial for optimizing system performance and streamlining workflows. By leveraging these tools effectively, users can enhance their ability to monitor, control, and troubleshoot various processes with greater precision and speed. This involves understanding the full range of features available and applying best practices for configuration and maintenance.

To achieve optimal results, it is essential to familiarize oneself with the tool’s capabilities and customize settings according to specific needs. Regular updates and thorough training are also key components in ensuring that the software operates at its highest potential. By adopting these strategies, users can improve both the reliability and efficiency of their systems.

Testing and Commissioning Procedures

Ensuring the reliability and accuracy of protective devices is crucial for the safe and efficient operation of electrical systems. This section outlines the essential steps for evaluating and validating the performance of these devices before they are fully integrated into the system. Proper testing and commissioning ensure that the equipment functions correctly and meets the necessary standards.

Pre-Commissioning Checks

Before starting the formal testing process, it is important to conduct a series of preliminary inspections and verifications. These checks include confirming that all connections are secure, verifying that the equipment is correctly configured, and ensuring that the device is free from physical damage.

| Check | Description | Action |

|---|---|---|

| Connections | Verify that all wiring and terminals are properly connected and secure. | Inspect and tighten as necessary. |

| Configuration | Ensure that settings are accurately programmed according to system requirements. | Review and adjust settings as needed. |

| Physical Condition | Check for any visible signs of damage or wear. | Replace or repair damaged components. |

Testing Procedures

Once pre-commissioning checks are complete, proceed with functional testing to verify the performance of the device. This includes conducting both static and dynamic tests to confirm that the device responds appropriately to simulated fault conditions and operates within its specified parameters.

Begin by applying test signals and monitoring the device’s responses. Compare the actual performance with the expected outcomes to identify any discrepancies. Detailed documentation of test results is essential for troubleshooting and future reference.

Ensuring Proper Relay Functionality

To maintain the optimal performance of electrical switching devices, it is crucial to adhere to best practices for their operation and maintenance. Proper functionality is vital for the reliability and efficiency of electrical systems, which hinges on regular inspection, correct installation, and prompt troubleshooting. Ensuring that these devices operate within their specified parameters helps prevent malfunctions and extends their lifespan.

Begin by carefully reviewing the device’s specifications and installation guidelines to ensure it is set up correctly. Pay attention to the wiring connections and verify that they are secure and correctly matched to the device’s requirements. Regular testing and calibration should be part of routine maintenance to identify and address potential issues before they impact performance.

Additionally, environmental conditions such as temperature, humidity, and vibration should be considered, as they can affect the device’s functionality. Implementing preventive measures to protect against adverse conditions will contribute to the device’s consistent performance and reliability.