Welcome to the comprehensive guide designed to assist you with the advanced sensor technology utilized in modern applications. This document serves as a valuable resource for effectively harnessing the full potential of your cutting-edge detection equipment. Here, you will find essential information and detailed explanations to optimize your understanding and usage of the system.

In this guide, you will explore a range of functionalities, installation procedures, and troubleshooting tips that are crucial for ensuring the optimal performance of your sophisticated sensor unit. With clear instructions and practical advice, you will be well-equipped to achieve the best results from your technological investment.

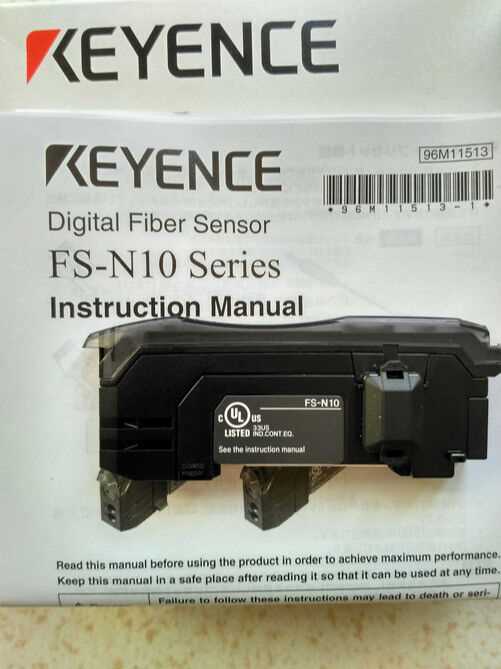

Overview of Keyence FS N10 Series

This section provides an in-depth look at a range of advanced optical sensors designed for various industrial applications. These sensors are known for their high precision and versatility, making them ideal for tasks requiring accurate detection and measurement.

The following highlights the key features and capabilities of these sensors:

- High resolution for precise detection and measurement.

- Versatile applications across different industries.

- Robust performance in challenging environments.

- Ease of integration with existing systems.

Understanding these attributes can help in selecting the right sensor for specific needs, ensuring optimal performance and efficiency in various tasks.

Understanding Key Features and Benefits

In this section, we will delve into the primary attributes and advantages of this advanced sensor technology. By examining its core functionalities and practical benefits, you will gain a comprehensive understanding of how these innovations can enhance operational efficiency and performance.

Enhanced Precision and Reliability

These sensors are designed to provide exceptional accuracy and consistent performance in various applications. Their ability to detect and measure with high precision ensures reliable results, which are crucial for maintaining high standards in industrial processes.

Versatile Application and Ease of Use

With a focus on user-friendliness, these devices offer flexible installation options and intuitive operation. Their adaptability to different environments and tasks makes them suitable for a wide range of industrial settings, contributing to their overall effectiveness and convenience.

Installation and Setup Guidelines

Ensuring proper installation and configuration is crucial for the effective operation of your optical sensor system. The following instructions will guide you through the essential steps to achieve optimal performance and functionality.

Begin by selecting an appropriate location for your device. The chosen spot should be stable, clean, and free from environmental factors that could interfere with the sensor’s operation, such as excessive vibrations or extreme temperatures. Proper alignment with the target area is also necessary to ensure accurate detection and measurement.

Follow these steps to complete the installation:

| Step | Description |

|---|---|

| 1 | Unbox the equipment and verify that all components are present as per the provided checklist. |

| 2 | Mount the sensor securely using the provided brackets and fasteners. Ensure it is positioned correctly relative to the target surface. |

| 3 | Connect the necessary cables to the sensor. Refer to the connection guide to ensure correct wiring. |

| 4 | Power up the device and perform an initial test to confirm that it is functioning as expected. |

| 5 | Adjust the sensor settings according to the specific requirements of your application. Refer to the configuration guide for detailed instructions. |

| 6 | Conduct a final inspection to ensure everything is properly set up and operational. |

By adhering to these guidelines, you can achieve a successful s

Configuration Options and Customization

When it comes to tailoring your device to meet specific needs, understanding the available configuration options and customization features is crucial. These settings allow you to adapt the device’s performance and functionalities to fit unique operational requirements. By exploring and adjusting these parameters, you can optimize the device for various tasks and environments.

Adjustment Settings: The device offers a range of adjustment settings that let you fine-tune its behavior. This includes modifying sensitivity levels, response times, and operational modes to better align with the desired application.

Personalization Features: Beyond basic adjustments, the device allows for extensive personalization. This involves configuring user interfaces, setting preferences for notifications, and selecting operational profiles that cater to specific tasks.

Advanced Customization: For more complex needs, advanced customization options are available. This includes integrating the device with other systems, programming custom functions, and creating unique profiles that enhance overall functionality.

Common Troubleshooting Tips

When dealing with technical equipment, it’s essential to address and resolve issues promptly to ensure optimal performance. This section provides general advice for diagnosing and fixing frequent problems you might encounter.

Power and Connection Issues

- Check if the device is properly connected to a power source.

- Ensure all cables and connectors are securely attached.

- Inspect the power cord for any visible damage.

- Verify that the power supply matches the device’s specifications.

Performance and Accuracy Concerns

- Confirm that the device is correctly calibrated.

- Clean any lenses or sensors as dust or dirt can affect performance.

- Review the settings to ensure they match the required specifications.

- Restart the device to reset any temporary issues.

Maintenance and Care Recommendations

Proper upkeep and care are essential for ensuring the longevity and optimal performance of your optical sensor. Regular attention helps in preventing potential issues and maintaining reliable operation.

- Keep the sensor clean by wiping it with a soft, dry cloth. Avoid using abrasive materials or harsh chemicals.

- Inspect the sensor regularly for any signs of damage or wear. Address any issues promptly to prevent further problems.

- Ensure that the sensor is installed correctly and securely to avoid misalignment and potential operational issues.

- Check connections and wiring to make sure they are intact and free of damage.

- Follow the manufacturer’s recommendations for calibration and adjustment to maintain accuracy.

Adhering to these maintenance practices will help you achieve consistent and reliable performance from your optical sensor.

Advanced Functions and Applications

Exploring the sophisticated capabilities and diverse uses of this sensor system can significantly enhance operational efficiency and precision in various environments. These advanced features offer greater control and adaptability, allowing for the fine-tuning of performance to meet specific application needs.

By leveraging customizable settings and advanced programming options, users can optimize the system for complex tasks and challenging conditions. This flexibility not only improves functionality but also extends the range of possible applications, making the technology versatile across different industries and use cases.