Understanding the intricacies of air-fuel ratio monitoring is essential for optimizing engine performance and efficiency. This guide aims to provide a thorough overview of advanced systems designed to measure and analyze the composition of exhaust gases, ensuring that your engine operates at its peak potential.

In the following sections, you will explore the key features and operational principles of these sophisticated devices. The focus will be on how to effectively use these tools to fine-tune your engine’s performance and achieve accurate readings for improved fuel efficiency and reduced emissions.

Whether you’re a seasoned professional or a hobbyist, mastering the use of these advanced systems will significantly enhance your understanding of engine dynamics and contribute to better overall vehicle performance.

This section provides an in-depth look at the various characteristics and advantages of the advanced air-fuel ratio monitoring system. Designed for precision and reliability, the system offers numerous enhancements to performance and usability.

- Enhanced Accuracy: The system ensures precise measurement of air-fuel mixtures, contributing to optimal engine performance and efficiency.

- Real-time Data: Continuous monitoring provides immediate feedback, allowing for timely adjustments and improved tuning outcomes.

- Durability: Constructed with high-quality materials, the system is built to withstand demanding conditions and extend its lifespan.

- User-friendly Interface: The intuitive design facilitates easy navigation and interpretation of data, making it accessible for both professionals and enthusiasts.

- Comprehensive Reporting: Detailed data analysis helps in understanding engine behavior, enhancing overall vehicle performance.

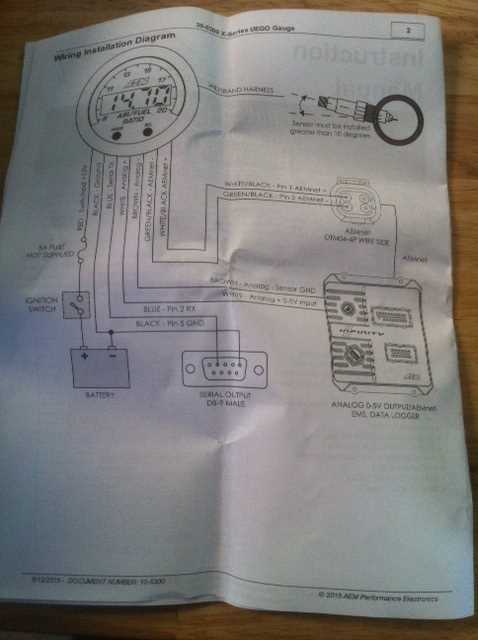

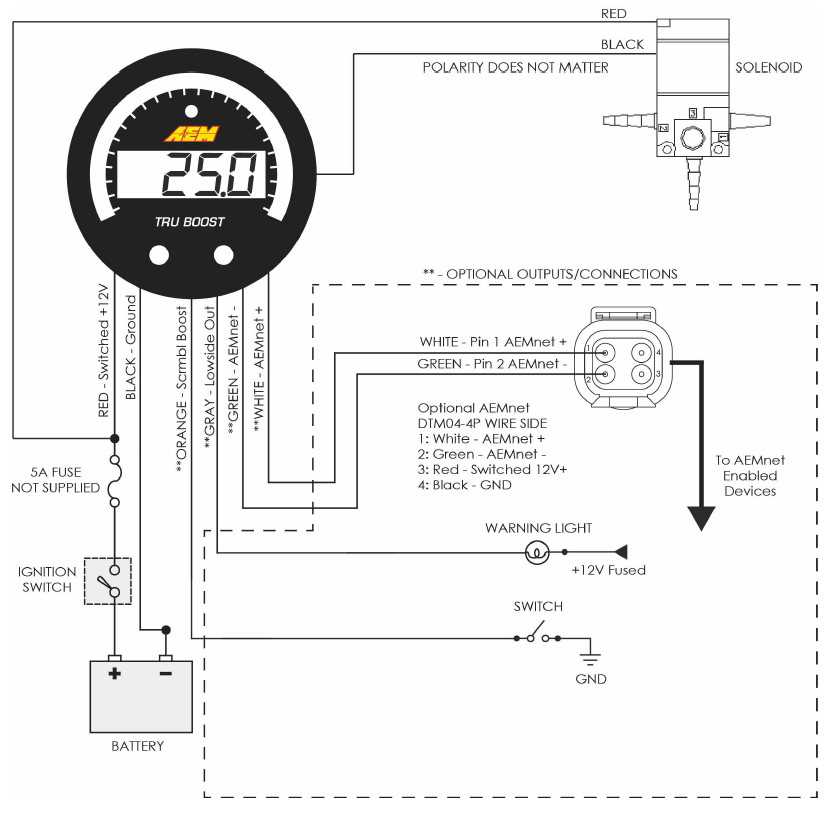

Installation Guidelines for the Sensor

Proper setup of the measurement device is crucial for accurate data collection and performance. Ensure that the sensor is installed in a location that provides reliable readings and is protected from environmental factors that might impact its functionality.

Begin by selecting an optimal mounting point that offers clear access to the exhaust stream. The sensor should be positioned in a manner that allows it to measure the exhaust gases effectively without interference. Avoid locations that are prone to excessive heat or mechanical vibrations.

Secure the sensor firmly to prevent movement and ensure stable readings. Use appropriate mounting hardware and follow the manufacturer’s recommendations for installation. Verify all connections and ensure that the sensor is properly aligned to avoid any measurement inaccuracies.

After installation, calibrate the sensor as per the guidelines to confirm that it is functioning correctly. Regular maintenance and periodic checks will help to maintain accuracy and prolong the lifespan of the sensor.

Calibration and Setup Procedures

Accurate calibration and setup are crucial for optimal performance and reliability of your measurement system. This section provides detailed steps and guidance to ensure proper configuration of the device. Following these procedures will help achieve precise readings and maintain the efficiency of the equipment.

Initial Calibration

Begin by setting up the device in a stable environment to avoid interference that may affect the calibration process. Ensure that all connections are secure and that the device is powered on. The initial calibration involves adjusting the system to a known reference point, which serves as the baseline for all future measurements.

Configuration Settings

Once the initial calibration is completed, proceed with configuring the device settings to match your specific requirements. This includes adjusting parameters such as measurement ranges, response times, and other relevant settings. Ensure that all adjustments are made according to the manufacturer’s recommendations for optimal accuracy.

| Step | Description |

|---|---|

| 1 | Power on the device and ensure stable setup. |

| 2 | Perform initial calibration with a reference standard. |

| 3 | Adjust configuration settings according to requirements. |

| 4 | Verify accuracy with test measurements. |

Data Interpretation and Analysis

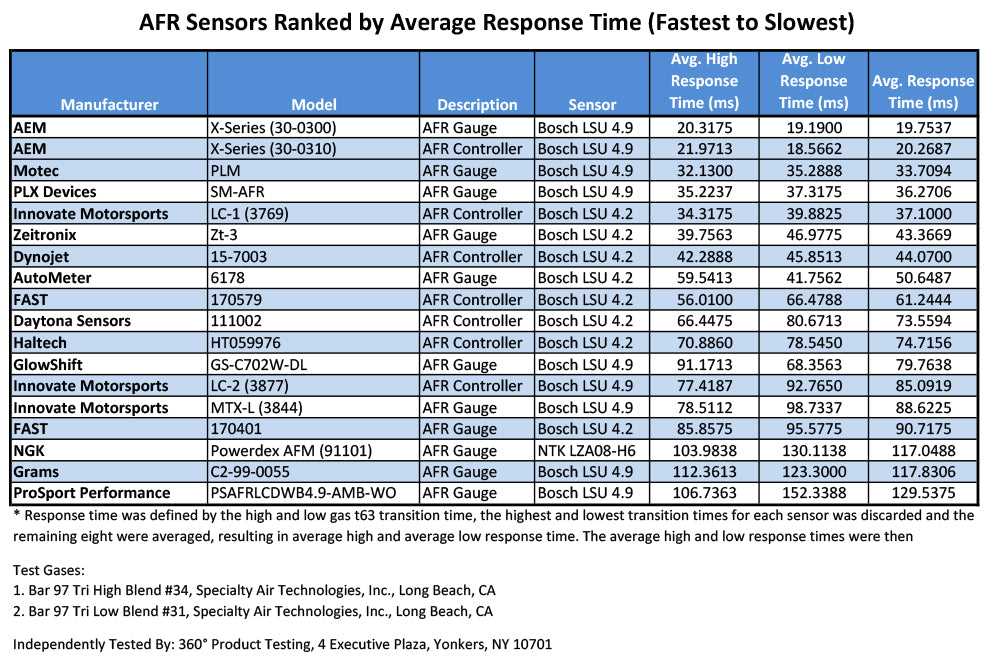

Understanding the data collected by your vehicle’s monitoring system is crucial for accurate performance tuning. Proper interpretation involves analyzing the various metrics provided by the device to ensure optimal engine operation. By scrutinizing these metrics, you can make informed decisions that enhance your vehicle’s efficiency and performance.

Key Metrics and Their Significance

Among the key metrics you will encounter are air-fuel ratios, exhaust temperatures, and lambda values. Air-fuel ratios indicate the balance between fuel and air entering the engine, crucial for maintaining efficient combustion. Exhaust temperatures provide insights into the engine’s operating conditions and potential overheating issues. Lambda values help assess the engine’s air-fuel mixture and make necessary adjustments.

Making Adjustments Based on Data

Once you have analyzed the data, it’s essential to make appropriate adjustments to your engine settings. Fine-tuning the air-fuel mixture or adjusting other parameters based on the collected data ensures that the engine runs smoothly and efficiently. This ongoing process helps maintain peak performance and prolongs the engine’s lifespan.

Maintenance and Troubleshooting Tips

Keeping your equipment in optimal condition and resolving issues promptly can greatly enhance its performance and longevity. Regular upkeep and quick fixes are essential for ensuring that everything operates smoothly and any potential problems are addressed before they escalate.

Routine Care and Inspection

Consistent maintenance involves checking for wear and tear, ensuring all components are securely connected, and cleaning parts as needed. Regular inspections can help identify minor issues early, preventing more serious complications down the line. Follow the manufacturer’s guidelines for maintenance intervals and procedures to ensure the best results.

Troubleshooting Common Issues

If problems arise, start by reviewing the basic functionality and checking for obvious faults. Consult the troubleshooting section for common symptoms and solutions. Address simple issues first, such as loose connections or incorrect settings, before seeking professional assistance if needed. Understanding these basic troubleshooting steps can save time and resources.