Embarking on a project that involves intricate cutting tasks requires a thorough understanding of your power tool. To achieve precision and efficiency, knowing the ins and outs of the equipment you are using is crucial. This section provides a comprehensive overview of how to get the most out of your device, ensuring that each cut is executed with accuracy and ease.

From setting up the tool to maintaining optimal performance, this guide will walk you through every step necessary for mastering its use. Whether you’re a novice or an experienced craftsman, having a clear grasp of operational techniques and safety measures will enhance your overall experience and results.

Detailed instructions and tips will help you navigate through various features and adjustments, making it easier to handle complex tasks with confidence. By familiarizing yourself with the correct procedures and practices, you’ll be better equipped to tackle any project with your cutting tool.

Understanding Your Ryobi Jigsaw

Getting acquainted with your cutting tool is essential for achieving optimal performance and safety. This section will guide you through the fundamental aspects of using this versatile power saw, designed for precise cutting tasks. By grasping its components and functions, you will be better prepared to utilize it effectively and maintain it properly.

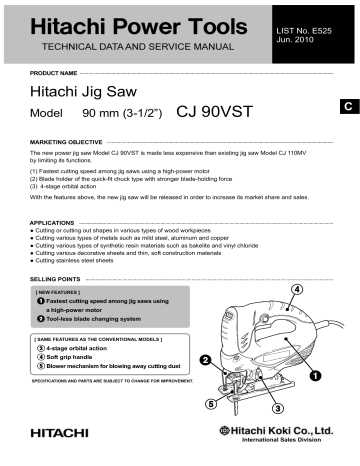

Key Components

Your power saw features several crucial parts that work together to deliver accurate cuts. The base plate provides stability and can be adjusted for different cutting angles. The blade, which is the cutting element, comes in various types depending on the material you’re working with. Understanding how to install and adjust the blade is vital for efficient operation.

Operating Principles

To operate the tool effectively, familiarize yourself with the trigger mechanism and speed settings. The trigger controls the activation and deactivation of the saw, while the speed settings allow you to adjust the cutting speed according to the material. Proper technique, including maintaining a steady hand and guiding the saw along your cutting line, ensures clean and precise cuts.

By understanding these basic elements, you’ll enhance your proficiency and safety while using the saw, making your projects more enjoyable and successful.

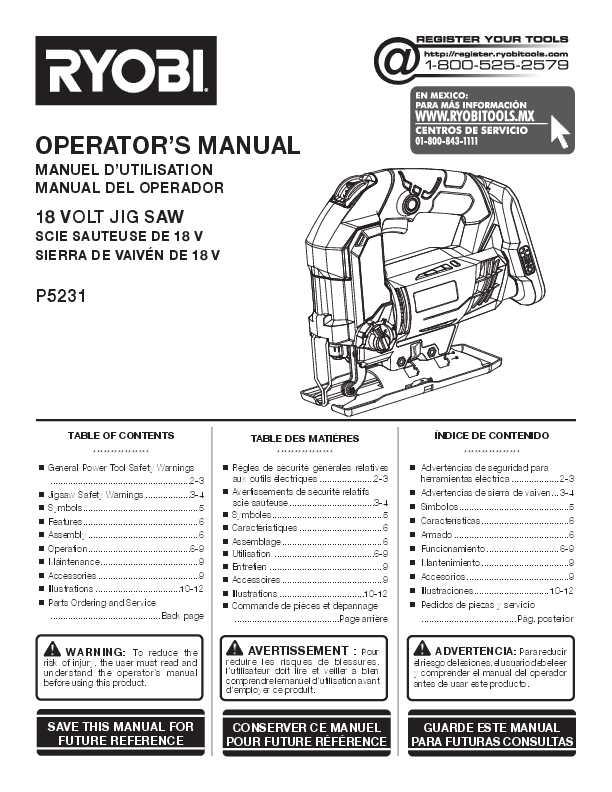

How to Assemble the Tool

Assembling your new power tool is a straightforward process that ensures its proper function and safety. Begin by carefully unpacking all components and laying them out on a clean surface. This will help you verify that you have everything needed for assembly.

Next, identify each part and consult the provided assembly guide to match components correctly. Follow the sequential steps to connect parts securely. Make sure all fittings are tightened properly to avoid any loose connections that could impact performance.

Once assembled, inspect the tool to ensure it is fully put together and operational. Testing the tool briefly will confirm that it is ready for use and functioning as intended.

Basic Operation and Safety Tips

Understanding how to properly use and handle your cutting tool is crucial for both effective results and personal safety. This section will guide you through essential procedures and safety practices to ensure a smooth and secure experience while operating your equipment.

Operation Guidelines: Before beginning any task, always make sure to familiarize yourself with the device’s controls and settings. Properly adjust the cutting depth and speed according to the material you are working with. Secure your workpiece firmly to prevent any movement that could affect the accuracy of your cuts.

Safety Precautions: Always wear appropriate personal protective equipment such as safety glasses and gloves to shield yourself from debris and sharp edges. Ensure that the tool is unplugged or the battery is removed when changing blades or making adjustments. Keep your workspace clean and free of clutter to avoid accidents. Never bypass safety features or operate the tool with damaged components.

By adhering to these basic operation and safety tips, you can ensure both effective performance and a safer working environment.

Choosing the Right Blades

Selecting the appropriate cutting blades is crucial for achieving the best results in your projects. The choice of blade directly impacts the precision, efficiency, and quality of the cuts. Different types of blades are designed for specific materials and cutting techniques, so understanding their characteristics is essential for optimal performance.

Blades come in various shapes and sizes, each suited to particular tasks. Factors such as the material being cut, the desired cut type, and the machine’s capabilities should guide your selection process. To assist in making an informed decision, here is a brief overview of common blade types and their ideal applications:

| Blade Type | Material | Application |

|---|---|---|

| High-Speed Steel (HSS) | Metal | Suitable for cutting through metals and hard materials. |

| Cobalt | Metal | Ideal for cutting tougher metals and alloys. |

| Bi-Metal | Wood, Metal | Versatile blade for both wood and metal cutting, offering durability and flexibility. |

| Carbide-Tipped | Hard Materials | Designed for cutting through very hard materials, such as ceramics and glass. |

| Wood Cutting | Wood | Specifically engineered for clean and precise wood cuts. |

Each blade type serves a unique purpose and selecting the right one ensures better results and extends the life of your equipment. Always consult your tool’s specifications and the blade manufacturer’s recommendations to make the best choice for your needs.

Maintaining Your Jigsaw for Longevity

Proper care and routine upkeep are essential for extending the lifespan and ensuring the optimal performance of your cutting tool. Regular maintenance prevents unexpected breakdowns and helps sustain the efficiency of the device over time. By following a few straightforward steps, you can avoid common issues and keep your equipment in top condition.

Regular Cleaning: After each use, remove dust and debris from the tool. Accumulation of material can affect the motor and blade functionality. Use a soft brush or compressed air to clean the internal and external components.

Blade Inspection: Frequently check the cutting blade for signs of wear or damage. Replace dull or broken blades promptly to maintain precision and safety during operation.

Lubrication: Apply lubricant to moving parts as recommended. Proper lubrication reduces friction and wear, ensuring smooth operation and prolonging the life of the tool.

Check Electrical Components: Inspect the power cord and plug regularly for any signs of damage. Ensure that connections are secure and that there are no frayed wires. Proper electrical maintenance is crucial for safe and reliable performance.

Storage: Store the tool in a dry, clean environment when not in use. Avoid exposure to extreme temperatures or moisture, which can cause corrosion and deterioration of components.

By adhering to these maintenance practices, you can enjoy the benefits of a well-maintained cutting tool, ensuring its longevity and reliability for many projects to come.

Troubleshooting Common Issues

When working with power tools, encountering operational problems can be frustrating. Understanding how to address these issues effectively can save time and ensure optimal performance. This section provides guidance on resolving frequent challenges that users might face, helping to maintain efficiency and safety.

- Tool Not Starting:

- Check if the tool is properly plugged in or if the battery is fully charged.

- Inspect the power switch for any damage or malfunction.

- Ensure that all safety features are properly engaged.

- Inconsistent Cutting Performance:

- Verify that the blade is correctly installed and securely fastened.

- Examine the blade for dullness or damage; replace if necessary.

- Adjust the speed settings if available, to match the material being cut.

- Excessive Vibration:

- Check for loose or damaged components and tighten or replace them as needed.

- Ensure that the blade is properly aligned and balanced.

- Inspect the tool’s housing for any signs of wear or misalignment.

- Overheating:

- Allow the tool to cool down before continued use.

- Ensure adequate ventilation during operation to prevent heat buildup.

- Check for and remove any debris or obstructions that might restrict airflow.

Recommended Accessories and Upgrades

Enhancing your cutting tool experience can significantly impact your project’s efficiency and precision. There are several enhancements available that can optimize your tool’s performance and broaden its versatility. Consider the following options to get the most out of your device:

- Blades: Different blade types and materials can be used to achieve specific cuts. Selecting blades designed for various materials, such as wood, metal, or plastic, can enhance the accuracy and quality of your cuts.

- Guide Rails: Adding guide rails helps to ensure straight, precise cuts by providing stability and reducing blade wobble. They are especially useful for long, straight cuts.

- Dust Blower Attachments: Keeping your cutting line clear of debris is crucial for accurate results. Dust blower attachments help maintain visibility and cleanliness while you work.

- Base Plate Extensions: For increased support and stability, base plate extensions can be added. They help improve balance and reduce the risk of tipping during operation.

- Comfort Handles: Ergonomic handles can reduce hand fatigue and improve control during extended use. Look for handles that are designed for comfort and reduce vibration.

- Variable Speed Controls: Tools with adjustable speed settings allow you to tailor the cutting speed to the material and task, improving both performance and accuracy.

Incorporating these accessories and upgrades can enhance your tool’s functionality and help you achieve professional-quality results with ease.