Mastering the operation of advanced fluid control systems is essential for ensuring optimal performance and longevity. Whether you are overseeing a complex network or managing a simple setup, understanding the correct procedures is key to maintaining efficiency and safety. This guide aims to equip you with the necessary knowledge to operate and maintain these systems effectively.

Within this document, you will find a comprehensive breakdown of the essential steps and considerations. From initial setup to routine maintenance, each section is designed to provide clear and concise instructions, ensuring that users of all experience levels can confidently navigate the process.

By following the outlined procedures, you will be able to achieve consistent and reliable operation, minimizing the risk of common issues and extending the lifespan of your equipment. Proper care and attention to detail will not only enhance the performance but also contribute to overall safety and reliability in various applications.

Overview of Grundfos Pump Models

Understanding the variety of available devices is crucial for selecting the most suitable option for specific applications. This section provides a summary of the different categories, highlighting their unique features and the specific scenarios where they excel.

Circulators: Designed for efficient fluid movement in heating and cooling systems, these models ensure optimal energy consumption and reliable performance. They are often employed in both residential and commercial environments where consistent flow rates are essential.

Submersible Units: These variants are built to operate underwater, making them ideal for handling groundwater extraction, drainage, and similar tasks. Their robust construction and specialized design ensure long-lasting operation even in challenging conditions.

Pressure Boosters: Engineered to maintain or enhance flow in systems with low natural pressure, these models are perfect for applications requiring a steady and powerful output. They are commonly used in multi-story buildings, irrigation systems, and industrial processes.

Dosing Systems: These devices are tailored for precise delivery of liquids, particularly in chemical processing, water treatment, and other industries where accuracy is paramount. They are equipped with advanced control features to ensure exact measurements and consistency.

Each category serves a distinct purpose, allowing users to choose the most appropriate solution based on the specific requirements of their project or system.

Key Features and Specifications

This section provides an overview of the essential characteristics and technical details that define the performance and capabilities of the equipment. Understanding these elements will help ensure optimal operation and longevity.

- High Efficiency: Designed with advanced technology to deliver superior energy efficiency, reducing power consumption while maintaining peak performance.

- Durable Construction: Built from high-quality materials to withstand demanding conditions, ensuring reliability and a long service life.

- Compact Design: Features a streamlined form that allows for easy integration into various systems, saving space without sacrificing functionality.

- Quiet Operation: Engineered to minimize noise levels, providing a quieter working environment.

- Versatile Compatibility: Suitable for a wide range of applications, compatible with different setups and operational requirements.

- Easy Maintenance: Designed for straightforward servicing, allowing for quick and hassle-free upkeep.

- Power Supply: Available in multiple voltage options to accommodate various power systems.

- Flow Rate: Offers a broad range of flow rates to meet diverse operational demands.

- Pressure Rating: Supports various pressure ratings, ensuring adaptability to different application needs.

- Temperature Range: Capable of operating efficiently within a wide temperature spectrum.

- Protection Class: Equipped with safety features to prevent damage from external factors like dust and water.

These features and specifications highlight the equipment’s advanced design, making it a reliable choice for a variety of applications.

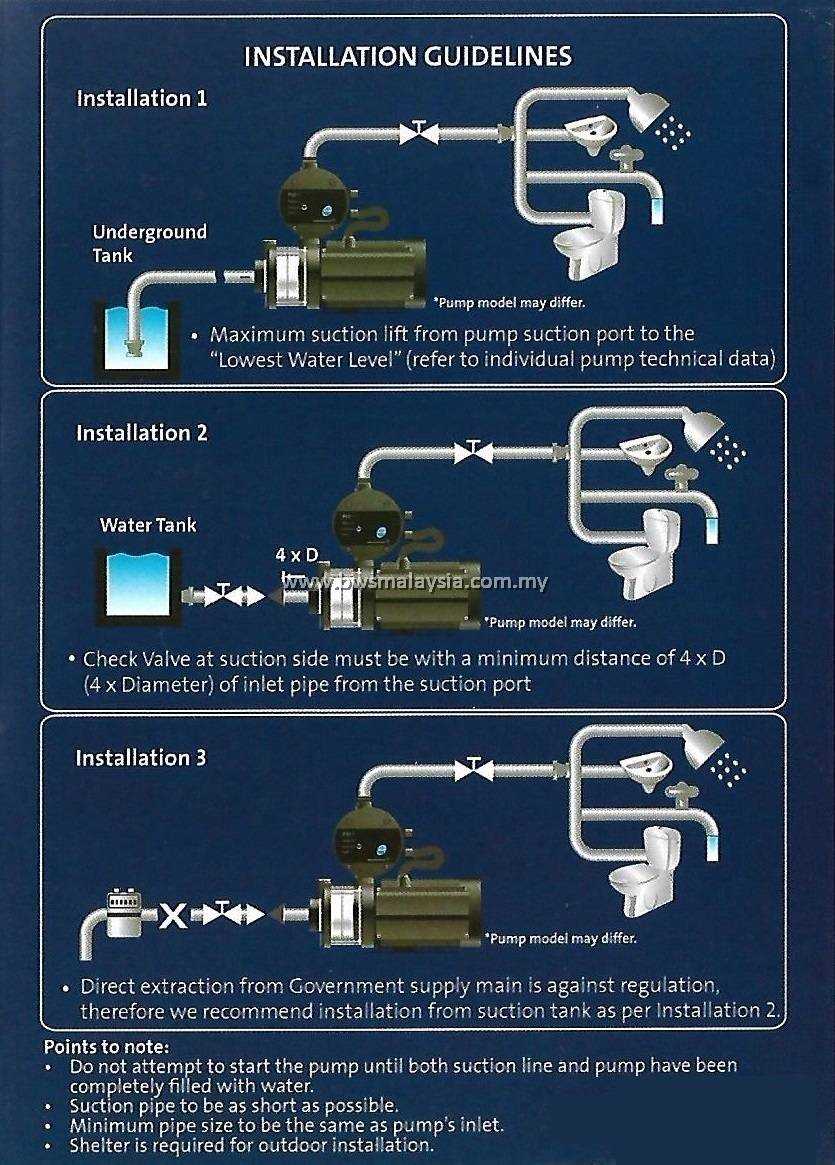

Installation Guide for Grundfos Pumps

Proper setup of your water-moving equipment is essential for ensuring efficient operation and long-term reliability. This section provides a comprehensive walkthrough for correctly setting up your unit, detailing each step to avoid common pitfalls and ensure optimal performance.

- Before starting, verify that all required components and tools are available.

- Ensure the installation site meets necessary environmental and structural requirements.

- Check compatibility with your existing system, including power supply and connections.

Next, proceed with connecting the device to the system:

- Position the unit securely on a stable surface, ensuring it is level and free from vibrations.

- Attach the inlet and outlet connections according to the specified guidelines, ensuring a tight seal to prevent leaks.

- Connect the power source, following all safety protocols to avoid electrical hazards.

After completing the setup, conduct a thorough inspection:

- Verify that all connections are secure and that there are no visible leaks.

- Check the alignment and stability of the equipment to prevent operational issues.

- Test the system to confirm that everything is functioning correctly.

Upon successful testing, your water-moving system is ready for operation. Regular maintenance and adherence to usage guidelines will ensure long-lasting performance.

Step-by-Step Setup Instructions

In this guide, you will find a clear and concise process for setting up your new device. The instructions below are designed to help you configure and start using your equipment with ease. Follow the steps in sequence to ensure everything is correctly installed and ready for operation.

1. Preparation

Before you begin, make sure you have all necessary tools and accessories. Ensure that the area where the device will be installed is clean and free of obstructions. Review any safety precautions to avoid accidents during setup.

2. Installation Process

| Step | Description |

|---|---|

| 1 | Unbox the equipment and inspect all components for any visible damage. |

| 2 | Position the device in the designated location, ensuring it is stable and level. |

| 3 | Connect all necessary cables or pipes securely according to the provided guidelines. |

| 4 | Power on the unit and configure the settings as per your requirements. |

| 5 | Test the system to confirm everything is functioning properly. |

Once all steps are completed, your device should be operational and ready for use. Regular maintenance and monitoring are recommended to ensure optimal performance over time.

Maintenance Tips for Grundfos Pumps

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. Consistent attention to the system’s components can prevent unexpected issues, minimize downtime, and extend the life of the entire setup.

Inspect Components Regularly: Routinely examine all parts for signs of wear and tear, including seals, bearings, and electrical connections. Early detection of any irregularities can prevent costly repairs in the future.

Keep the System Clean: Ensure that the environment around the system is free from dust, debris, and other contaminants. Clean the external surfaces periodically to prevent the buildup of harmful substances that could affect the functionality.

Monitor Operational Parameters: Regularly check the pressure, temperature, and flow rates to ensure they remain within the recommended range. Any deviation could indicate potential issues that require attention.

Lubricate Moving Parts: Apply lubrication to the necessary components as recommended by the manufacturer. Proper lubrication reduces friction, prevents overheating, and contributes to the smooth operation of the system.

Test Safety Features: Periodically verify that all safety mechanisms are functioning correctly. This includes pressure relief valves, alarms, and other protective devices that are crucial for safe operation.

By following these maintenance practices, you can help ensure that your system remains reliable, efficient, and durable over time.

Common Issues and Solutions

In this section, we will explore typical challenges that users may encounter during operation and provide practical solutions to address these issues. Understanding how to identify and resolve common operational problems ensures smoother performance and prolongs the equipment’s life.

Frequent Noise During Operation

Persistent noise can be a sign of underlying issues, such as air trapped in the system or improper installation. To mitigate this, ensure that all connections are secure and check for any air pockets. Bleeding the system may help remove trapped air, restoring quiet operation. If noise persists, inspect the mounting to confirm it is stable and correctly aligned.

Inconsistent Performance

Inconsistencies in performance often arise due to blockages or worn-out components. Regular maintenance, including cleaning filters and inspecting parts, is crucial. If performance continues to fluctuate, check for signs of wear and tear, and replace any damaged elements as needed. Ensuring the equipment is operating within the recommended parameters can also prevent performance issues.

By promptly addressing these common concerns, users can maintain optimal functionality and reduce the risk of more significant problems in the future.

Understanding Pump Controls

Managing the operation of modern water distribution systems involves mastering various control mechanisms. These controls are designed to regulate the performance of the system, ensuring efficient and reliable operation. Familiarizing yourself with these controls is essential for optimizing performance and addressing any potential issues that may arise.

Types of Control Interfaces

Control interfaces can vary widely depending on the system’s design and complexity. Here are some common types:

- Manual Controls: These require direct human input to adjust settings such as flow rate and pressure.

- Digital Interfaces: Utilize screens and buttons to allow precise adjustments and monitoring through a digital display.

- Automated Systems: Operate based on pre-set parameters or real-time data, reducing the need for manual intervention.

Key Control Features

Understanding the essential features of control systems can help in their effective use:

- Flow Rate Adjustment: Allows you to modify the rate at which water is distributed.

- Pressure Regulation: Ensures that the system maintains optimal pressure levels for various applications.

- Error Notifications: Alerts users to any malfunctions or operational issues.

Programming and Configuration Guide

This section provides essential information on setting up and adjusting the system to meet specific needs. Proper programming and configuration are crucial for optimal performance and efficiency. Following the guidelines will ensure that the system operates according to your preferences and requirements.

Initial Setup

To begin with, follow these steps to configure the system:

- Access the configuration interface through the control panel.

- Select the appropriate settings based on your operational requirements.

- Save and apply the settings to initialize the system.

Advanced Configuration

For more detailed adjustments, consider these additional options:

- Adjust operational parameters to fine-tune performance.

- Set up schedules for automatic adjustments and monitoring.

- Review system diagnostics to ensure all components are functioning correctly.