Maintaining and operating your cleaning device effectively requires a thorough understanding of its functionality. This section provides essential insights into the operation, features, and best practices for utilizing your equipment to achieve optimal results.

In this guide, you will find detailed explanations and helpful tips designed to enhance your experience. The aim is to ensure you are well-informed about every aspect of your equipment, from setup to usage and maintenance, to keep it performing at its best.

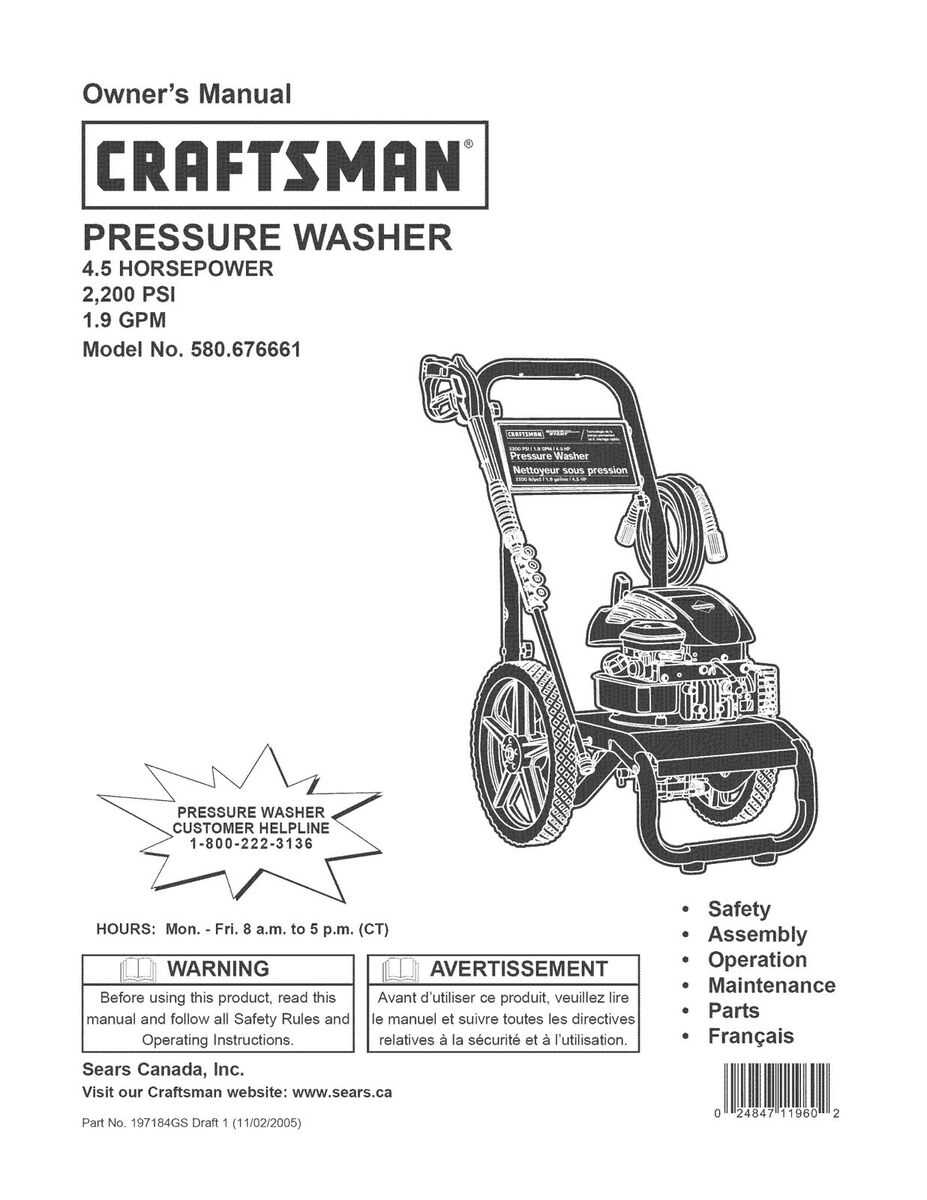

Understanding Your Craftsman Pressure Washer

Getting acquainted with your high-powered cleaning device is essential for optimal performance and longevity. This section will guide you through the fundamental aspects of your unit, including its key features, operational components, and maintenance routines. By familiarizing yourself with these elements, you’ll ensure efficient usage and extend the life of your equipment.

| Feature | Description |

|---|---|

| Power Unit | Generates the force necessary for cleaning various surfaces. |

| Water Pump | Pressurizes the water to enhance the cleaning process. |

| Hose and Nozzle | Directs and controls the flow of water for targeted cleaning. |

| Filter System | Prevents debris from entering the pump and causing damage. |

| Controls | Allow you to adjust settings such as pressure and flow rate. |

Understanding these components and their functions will help you operate your device effectively, ensuring that each cleaning task is performed efficiently and safely.

Key Features and Specifications

This section provides an overview of the essential attributes and technical details of the equipment. It highlights the various aspects that define its performance, usability, and overall efficiency. Understanding these key components is crucial for optimizing the use and maintenance of the device.

Performance: The equipment offers robust functionality with high output capabilities. It is designed to deliver exceptional results across different tasks, ensuring effective and reliable operation.

Design: Constructed with durability in mind, the unit features a well-engineered build that withstands regular usage and challenging conditions. Its ergonomic design enhances user comfort and ease of handling.

Technical Specifications: The device boasts impressive specifications, including powerful engine performance, high flow rates, and adjustable settings. These features contribute to its versatility and adaptability in various applications.

Safety Features: Equipped with essential safety mechanisms, the machine ensures secure operation. These features include automatic shut-off systems and protective measures that safeguard both the user and the equipment.

Assembly Instructions for Optimal Setup

To ensure your equipment performs at its best, following the assembly guidelines is crucial. Proper assembly not only guarantees functionality but also enhances the safety and longevity of the device. Begin by carefully reviewing the provided components and understanding each part’s role in the overall setup.

Preparing for Assembly

Before starting, gather all necessary tools and parts. Make sure you have the following:

- All components listed in the package

- Appropriate tools such as wrenches and screwdrivers

- A clean, flat workspace

Step-by-Step Assembly

Follow these steps for an effective setup:

- Place the main unit on the workspace.

- Attach the base components securely. Ensure that all bolts and screws are tightened according to the specifications.

- Connect the hoses and fittings as outlined in the schematic. Double-check that all connections are snug to prevent leaks.

- Install any additional parts such as handles or nozzles. Verify that they are firmly attached and positioned correctly.

- Perform a final inspection to ensure that all components are correctly assembled and that the equipment is stable.

Once the assembly is complete, conduct a brief test to confirm that the setup operates smoothly and without issues. Regular maintenance and periodic checks will help keep the equipment in top condition.

Step-by-Step Assembly Guide

Assembling your new equipment can be a straightforward process if you follow a clear, organized approach. This section provides a detailed guide to help you piece together your new device efficiently. Each step is designed to ensure that you understand the procedure and can complete the assembly with confidence.

Step 1: Begin by gathering all the components and tools required for the assembly. Ensure that you have everything on hand before starting to avoid interruptions.

Step 2: Follow the initial instructions to connect the primary sections of the device. Align the parts carefully to ensure a secure fit. It is crucial to make sure that each piece is correctly positioned before moving to the next step.

Step 3: Secure the connections using the provided fasteners or connectors. Tighten them appropriately, but be cautious not to over-tighten, which could damage the parts.

Step 4: Verify the assembly by checking all connections and fittings. Make sure everything is firmly in place and that there are no loose components.

Step 5: Conduct a final inspection to ensure that the assembly meets all required standards. Test the device according to the operational guidelines to confirm that it functions correctly.

By following these steps carefully, you will ensure a smooth assembly process and set up your new equipment efficiently.

Operating Guidelines for Effective Cleaning

To achieve optimal results when using a high-performance cleaning device, it’s essential to follow specific procedures. Proper handling and application techniques can significantly enhance the efficiency of the equipment, ensuring thorough and effective cleaning. This section provides key recommendations for utilizing your device to its fullest potential.

Preparation: Before initiating the cleaning process, ensure that the area is clear of any obstacles and that the device is properly set up. This includes checking water connections and ensuring that all components are securely attached. Pre-cleaning inspections are crucial for avoiding any operational issues during use.

Operation: When engaging the device, maintain a consistent distance from the surface being cleaned. This helps to prevent damage while ensuring even coverage. Adjust the settings according to the surface type to achieve the best results. Avoid lingering on one spot for too long, as this can lead to uneven cleaning.

Post-Use Maintenance: After completing the cleaning task, thoroughly rinse the device and store it in a dry location. Regular maintenance, including checking for any wear or damage, is essential for prolonging the lifespan of the equipment. Following these guidelines ensures that the device remains in excellent working condition for future use.

Safe and Efficient Usage Tips

Operating cleaning equipment requires careful attention to both safety and performance. By following a few simple guidelines, users can ensure that they maintain the longevity of their device while avoiding any potential hazards. Prioritizing safety will help achieve optimal cleaning results without unnecessary risks.

Proper Setup and Handling

Before starting any cleaning task, always inspect the equipment for any visible damage or loose components. Ensure that all connections are secure, and follow recommended procedures when attaching nozzles or hoses. It’s important to position the device on stable ground, away from any obstacles or surfaces that could cause it to tip or slide.

Maintaining Optimal Distance

During operation, maintain an appropriate distance from the surface being cleaned. This not only prevents accidental damage to delicate materials but also minimizes the risk of personal injury. Adjust the nozzle settings to match the cleaning task and avoid excessive force that may lead to unnecessary wear on the device or surface.

By staying aware of these key principles, users can maximize both safety and efficiency, ensuring their equipment functions effectively for a long time to come.

Maintenance Procedures for Longevity

Regular upkeep is essential to ensure that your equipment performs efficiently and remains in optimal condition for an extended period. By following consistent care routines, you can avoid common issues and extend the life of your device. Here, we outline some crucial steps to help maintain its reliability and functionality.

| Maintenance Task | Frequency | Description |

|---|---|---|

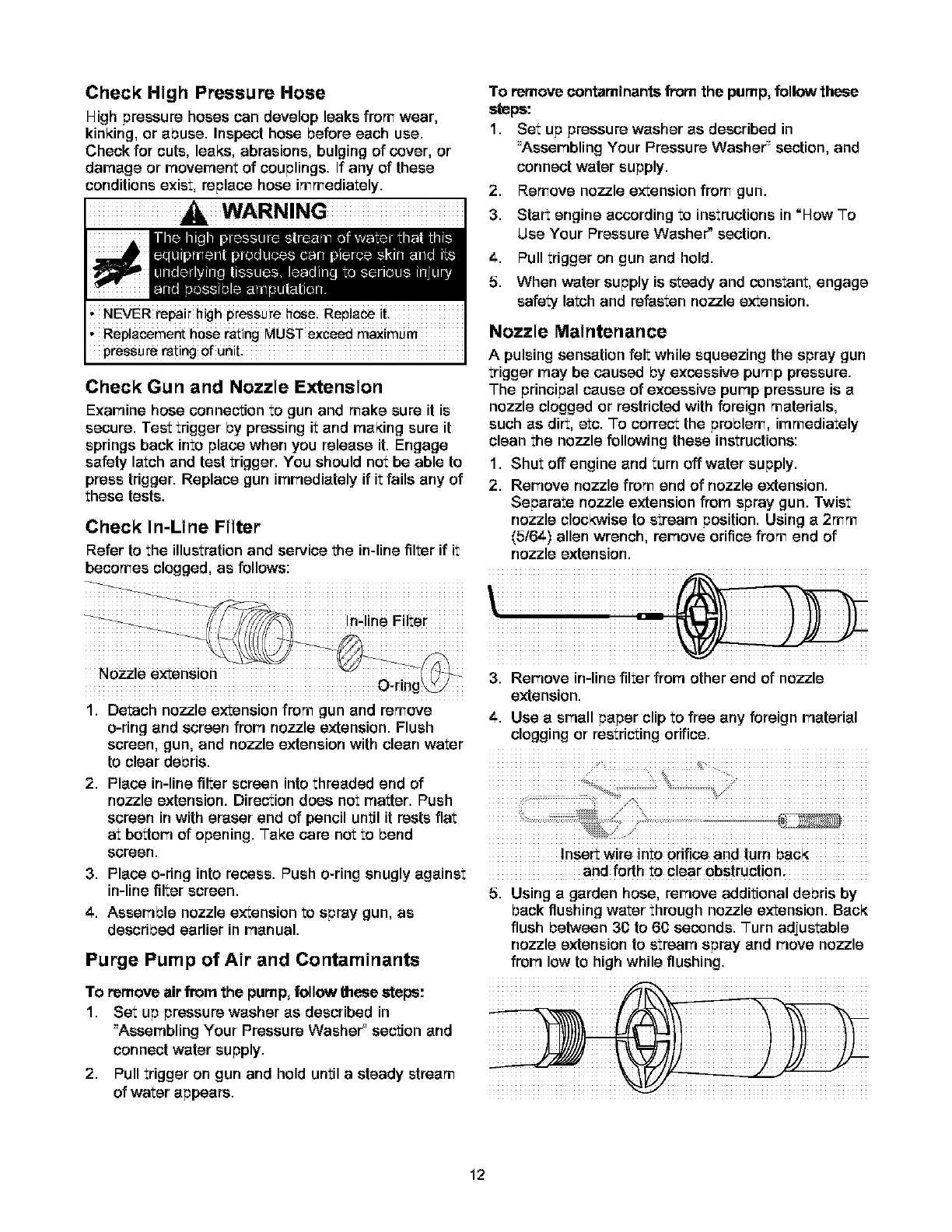

| Inspect Hoses and Connections | Before Each Use | Check for any visible wear, cracks, or leaks. Tighten any loose connections to prevent water loss or damage. |

| Clean Filters | Monthly | Remove and clean filters to ensure proper water flow and prevent blockages. Replace if necessary. |

| Change Oil | Every 50 Hours of Use | Regularly check oil levels and replace as needed to maintain engine efficiency and prevent overheating. |

| Examine Nozzles | Quarterly | Inspect nozzles for clogs or damage. Clean or replace to ensure consistent spray performance. |

| Flush System | End of Each Season | Flush the system with clean water to remove any detergent or debris buildup, which can corrode internal components. |

By adhering to these procedures, you not only protect your equipment but also enhance its efficiency, making it more reliable for future tasks.

Regular Maintenance and Troubleshooting

Proper upkeep and timely problem-solving are crucial for extending the lifespan and ensuring optimal performance of any equipment. Regular attention to key components and early detection of issues can help prevent costly repairs and downtime. This section provides an overview of essential maintenance practices and common troubleshooting steps to keep your device running smoothly.

Essential Maintenance Tips

- Inspect all hoses and fittings regularly for leaks, cracks, or wear. Replace damaged parts as needed.

- Clean the filters periodically to ensure proper flow and prevent clogs. Blocked filters can reduce efficiency and lead to overheating.

- Check the oil level in the engine, if applicable, and change it according to the manufacturer’s recommendations. Proper lubrication is key to avoiding engine damage.

- Examine the nozzles for debris buildup. Clean or replace them if the water flow appears weak or uneven.

- Keep the exterior of the unit free of dirt and grime to avoid corrosion or other damage to its surfaces.

Common Issues and How to Fix Them

- Low water flow: Check if the water supply is fully open, inspect hoses for blockages, and clean the nozzles.

- Engine won’t start: Ensure there is enough fuel, check the spark plug, and make sure the air filter is clean.

- Overheating: Make sure all vents are unobstructed and verify that the cooling system is functioning correctly.

- Poor performance: Examine the pump and engine for any wear or malfunctions, and inspect connections to avoid leaks.

By following these basic steps and staying alert to potential problems, you can maintain the efficiency of your equipment and extend its operational life. When issues arise, addressing them early will often result in easier fixes and reduced costs.