Exploring the world of homemade spirits offers both a fascinating hobby and a rewarding experience. Whether you’re a seasoned enthusiast or a curious beginner, understanding the nuances of the distillation process is crucial for achieving high-quality results. This guide aims to provide you with the essential knowledge and step-by-step procedures to confidently embark on your journey of crafting your own unique beverages.

Delving into this craft requires a clear understanding of the equipment and techniques involved. From preparing the ingredients to refining the final product, each stage plays a vital role in the outcome. This article will walk you through each phase, offering tips and insights to help you refine your skills and create exceptional spirits.

With careful attention to detail and a commitment to the process, you can master the art of distillation. This guide is designed to empower you with the information needed to get started, ensuring that you approach each step with confidence and precision.

Understanding the Basics of Vevor Moonshine Stills

Exploring the core principles of distillation systems allows enthusiasts to produce high-quality distilled products with greater control and precision. These systems are designed for individuals who are keen on crafting their own beverages or other distilled liquids at home. Gaining a solid understanding of the essential components and their functions is key to mastering the process.

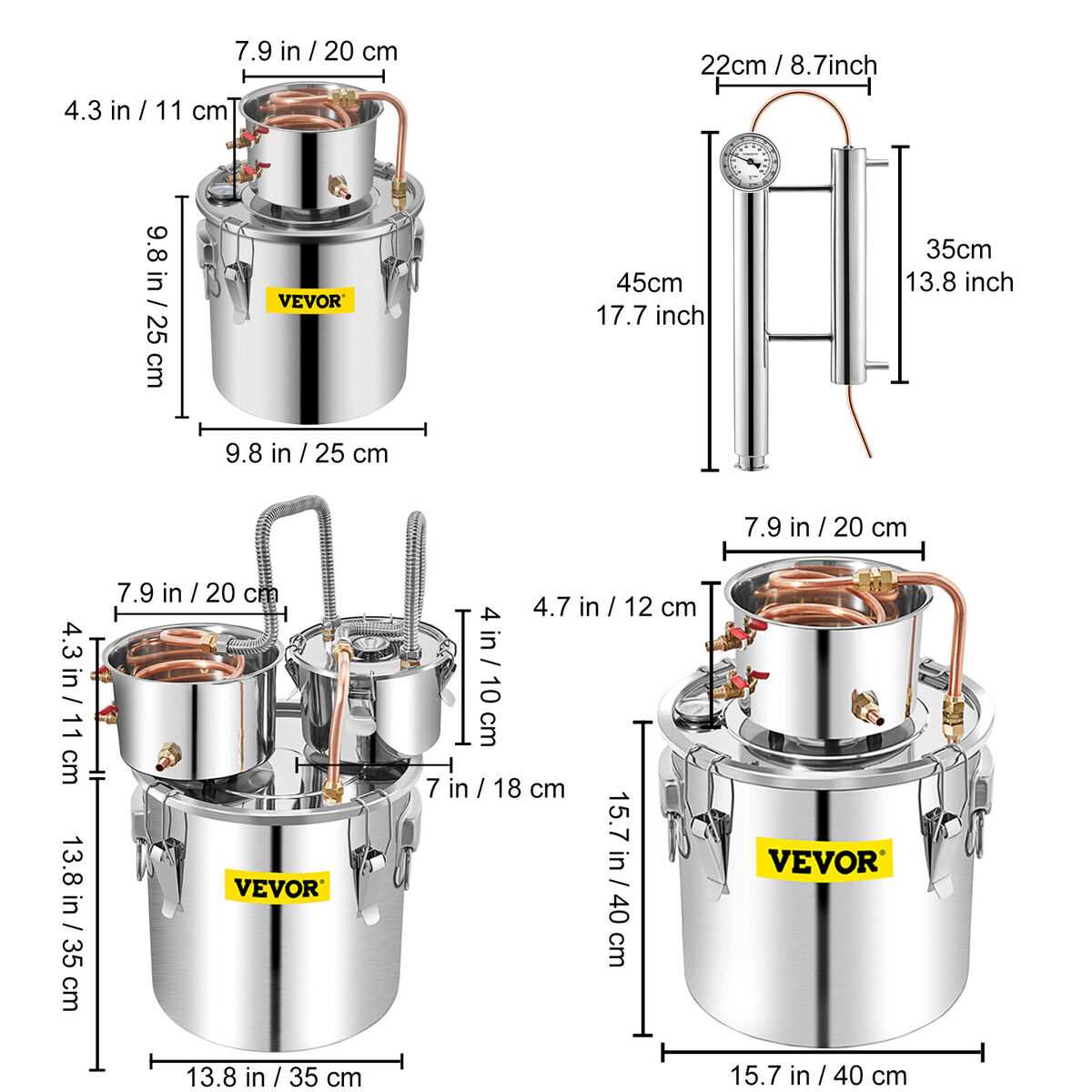

Key Components of a Distillation System

To efficiently operate a distillation apparatus, it’s important to familiarize yourself with its primary elements. Each part plays a crucial role in the overall process, ensuring that the outcome meets the desired standards. Below is an overview of the main parts typically found in such equipment:

| Component | Function |

|---|---|

| Boiler | The vessel where the initial liquid is heated, causing the transformation from liquid to vapor. |

| Condenser | Responsible for cooling the vapor back into a liquid form, capturing the refined product. |

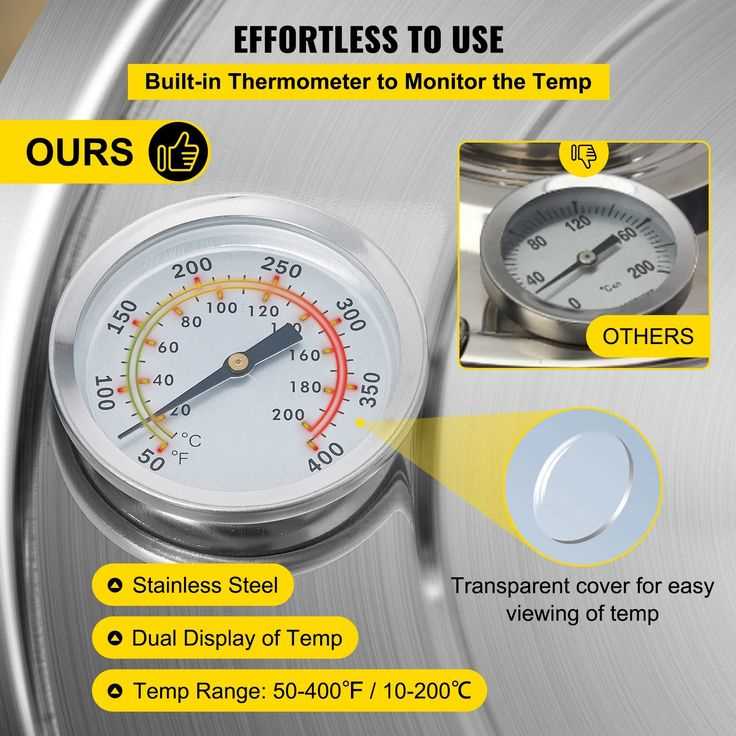

| Thermometer | Monitors the temperature, providing crucial information for maintaining optimal conditions. |

| Cooling System | Ensures that the condenser remains at the correct temperature to efficiently convert vapor back to liquid. |

Understanding the Process

Distillation is a straightforward yet delicate procedure. The process begins by heating the liquid mixture in the boiler until it vaporizes. The vapor then travels through a tube to the condenser, where it cools and returns to liquid form. By controlling the temperature and other variables, you can influence the quality and characteristics of the final product.

Step-by-Step Setup Process for Beginners

Setting up your new equipment can seem overwhelming at first, but with a clear and structured approach, the process becomes straightforward and manageable. This guide will walk you through each step, ensuring that you can confidently prepare and assemble everything needed for your first batch.

Unpacking and Inspection

Before starting the assembly, it’s important to unpack all the components and inspect them for any damage or missing parts. Lay everything out in an organized manner, and make sure to have all the necessary tools on hand.

- Carefully remove each component from the packaging, checking for any visible defects.

- Compare the components with the parts list provided, ensuring that nothing is missing.

- If everything is in order, clean the parts with warm water to remove any residues from manufacturing or packaging.

Assembling the Equipment

Once all parts are accounted for and cleaned, it’s time to begin the assembly. Follow these steps to ensure a secure and proper setup:

- Step 1: Start by assembling the base or main body, ensuring all connections are tight.

- Step 2: Attach the necessary tubing and connectors according to their designated slots.

- Step 3: Secure any additional components, such as valves or gauges, making sure they are properly aligned.

- Step 4: Ensure that all seals and gaskets are in place to prevent leaks during operation.

- Step 5: Once assembled, double-check all connections for stability and accuracy.

With the assembly complete, your equipment is now ready for use. Make sure to familiarize yourself with the operational guidelines before starting your first project.

Key Safety Precautions When Using the Still

Proper safety measures are crucial to ensure a secure and efficient distillation process. Adhering to recommended precautions minimizes risks and helps maintain a safe working environment. Below are key guidelines to follow to protect both the user and the equipment.

Understanding the Equipment

Before starting the distillation process, it is essential to thoroughly understand the components and how they operate. This knowledge will help prevent accidents and ensure smooth functioning.

- Familiarize yourself with all parts of the apparatus.

- Check for any signs of wear or damage before each use.

- Ensure all connections are tight and secure to prevent leaks.

Work Area Preparation

The environment in which you operate is just as important as understanding the equipment. A well-prepared workspace reduces the chances of accidents and promotes efficient work.

- Always work in a well-ventilated area to avoid the buildup of harmful fumes.

- Keep flammable materials far away from the heat source.

- Have a fire extinguisher nearby and know how to use it.

- Ensure the work surface is stable and clear of any obstructions.

By following these safety precautions, you can significantly reduce the risks associated with distillation, ensuring a safer and more productive experience.

Cleaning and Maintenance Tips for Longevity

Proper upkeep is essential to ensure the durability and efficiency of your equipment. Regular cleaning, along with careful maintenance, not only preserves the functionality but also extends the life of the device. By following the guidelines below, you can maintain optimal performance over the years.

Regular Cleaning

To keep your apparatus in prime condition, it is important to clean all components after each use. Begin by thoroughly rinsing all parts with warm water to remove any residue. For a deeper clean, use a mild detergent or a solution of vinegar and water. Be sure to rinse thoroughly to avoid any lingering chemicals that could affect future usage. Allow all parts to air dry completely before reassembly.

Routine Maintenance

Regularly inspect the seals, gaskets, and other critical components for wear and tear. Replace any parts showing signs of deterioration to maintain a tight seal and prevent leaks. Additionally, lubricate any moving parts as recommended to ensure smooth operation. Storing the equipment in a dry, cool place further protects it from damage, helping to maintain its longevity.

Troubleshooting Common Issues and Solutions

When using any complex equipment, challenges can arise that may disrupt the process or affect the quality of the output. Understanding and addressing these issues is crucial for ensuring smooth operation and optimal results. This section provides a guide to identifying and resolving some of the most frequent problems you might encounter during the process.

Inconsistent Temperature Readings

If you notice fluctuating temperature levels, it may indicate problems with the sensor or the heating element. First, ensure that the thermometer is properly positioned and calibrated. A faulty connection or a damaged probe can lead to incorrect readings. If the issue persists, consider checking the power source to ensure consistent energy supply.

Uneven Output Flow

An uneven flow can result from blockages or pressure imbalances within the system. To address this, inspect all valves and pathways for obstructions or leaks. Cleaning these components can often resolve the problem. Additionally, ensure that all seals are tight and that the system is properly assembled to maintain a consistent flow.

Optimizing Distillation Efficiency and Output

Enhancing the performance of your distillation process involves understanding and refining several key factors that influence both the yield and quality of the final product. By carefully managing these elements, you can achieve higher efficiency and more consistent results. This process requires a balance between technical knowledge and practical adjustments to your equipment and procedures.

Temperature Management

Maintaining precise temperature control is crucial for optimizing distillation. Each component in the mixture evaporates at different temperatures, so managing the heat source effectively helps to separate the desired product from unwanted substances. Using a high-quality thermometer and ensuring uniform heating can significantly impact the overall efficiency of the process.

Monitoring and Adjusting Pressure

Pressure levels within the distillation apparatus can affect the boiling points of the components in the mixture. Properly regulating pressure ensures that the distillation occurs under optimal conditions, which enhances both the yield and purity of the distillate. Regular checks and adjustments to the pressure settings can help maintain consistent performance throughout the process.