In this section, you will discover comprehensive guidance on utilizing advanced measuring devices designed to offer exact and reliable results. These tools are essential for achieving high levels of accuracy in various applications, from construction projects to detailed craft work.

Understanding the functionality of these devices will enable you to perform precise measurements efficiently. With a focus on ease of use and accuracy, you will learn how to make the most of these instruments, ensuring that your projects are completed with confidence and precision.

Additionally, you will find practical tips on optimizing performance and maintaining the equipment to prolong its lifespan. This information is crucial for achieving consistent results and maximizing the benefits of your measuring tools.

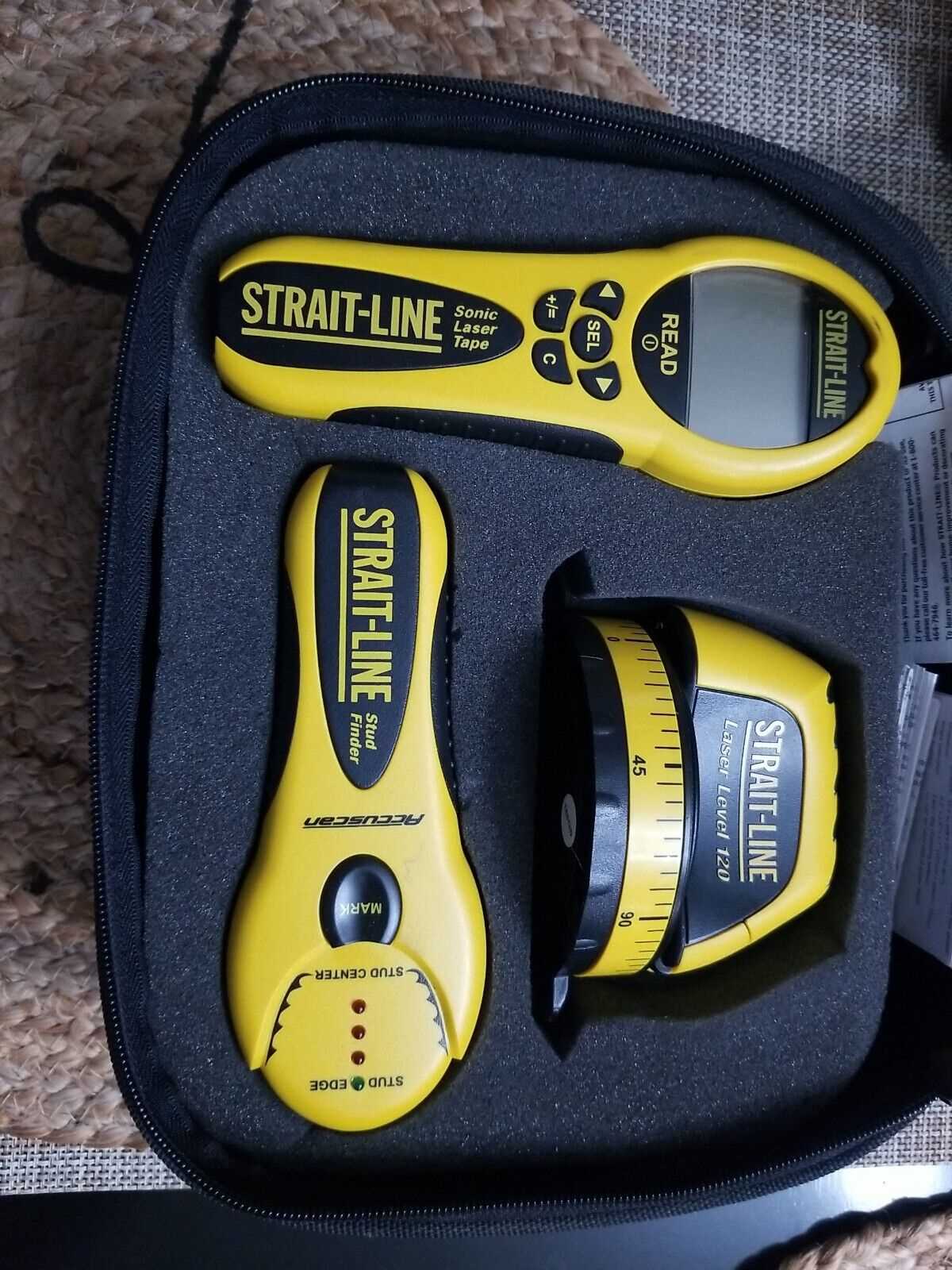

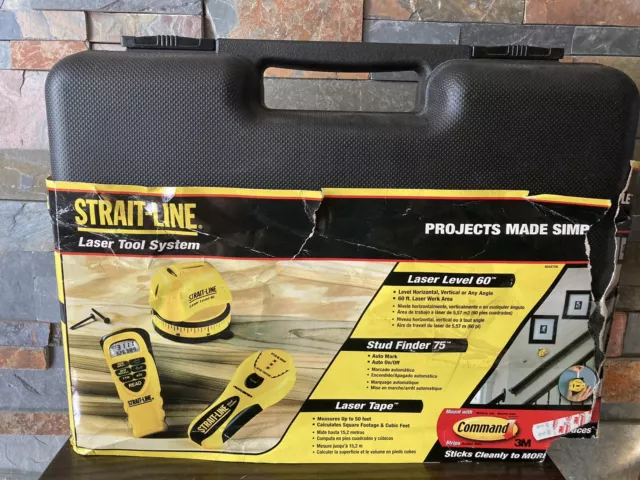

Overview of Strait-Line Laser Tape

This section provides a comprehensive look at an advanced measuring tool designed for precision and ease of use. This device integrates innovative technology to facilitate accurate distance measurements, ensuring efficiency in various applications. It is engineered to assist in achieving precise results with minimal effort.

Key features include:

| Feature | Description |

|---|---|

| Measurement Range | Offers a broad range suitable for different tasks. |

| Accuracy | Ensures high precision in measurements. |

| Ease of Use | Designed for straightforward operation. |

| Durability | Constructed to withstand various conditions. |

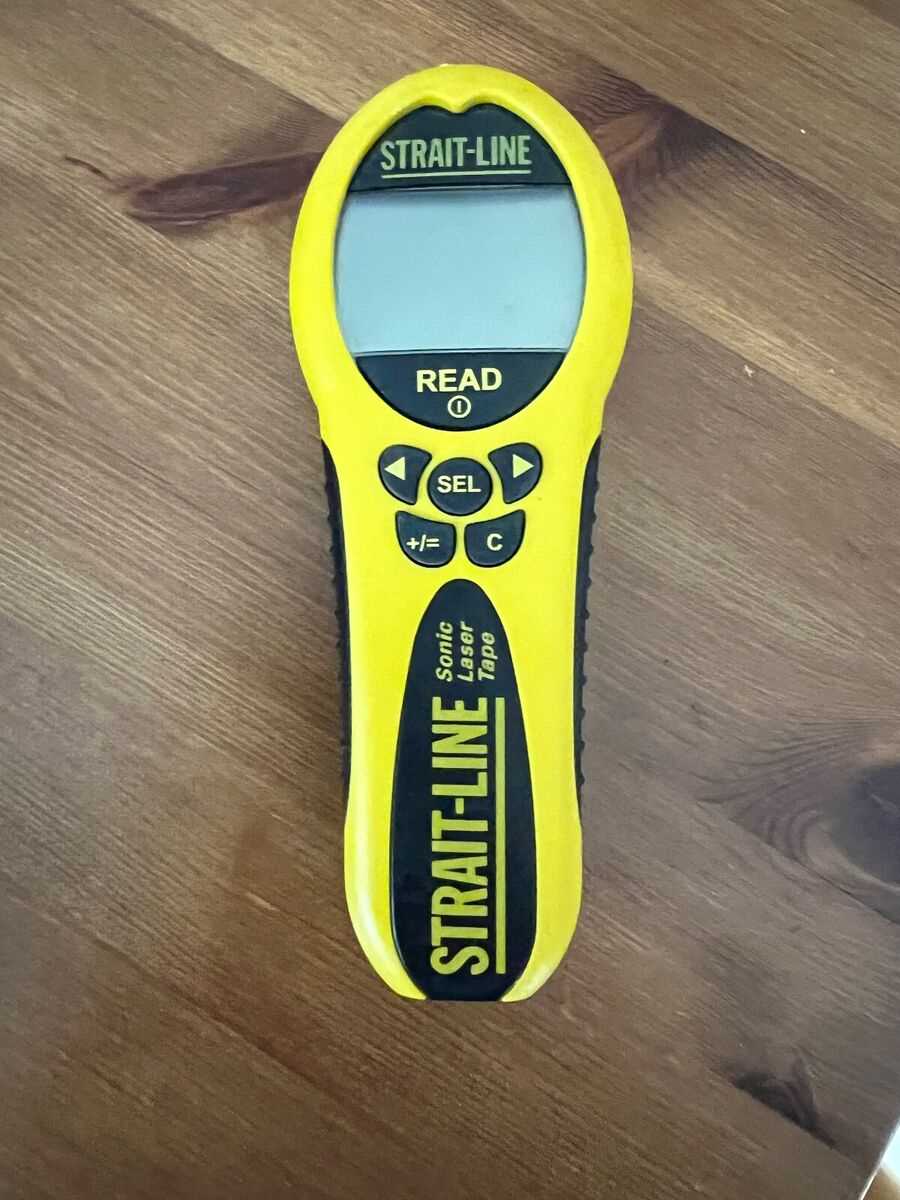

Understanding the Measurement Tool Functionality

When working with precision measurement devices, it’s essential to grasp how they operate to maximize their utility. These advanced tools combine optical technology with measuring capabilities to provide accurate readings over various distances. Understanding their fundamental components and features allows users to achieve precise results in different applications.

- Component Overview: These tools integrate an optical system that projects a beam to measure distances. Key components include the emitter, receiver, and display unit.

- Measurement Process: The device measures the time it takes for the beam to travel to a target and return. This time is then converted into distance, providing users with accurate measurements.

- Features and Functions: Advanced options may include memory storage, unit conversion, and various measurement modes such as continuous or single-point measurement.

Familiarity with these aspects ensures effective use and accurate results, whether for construction, interior design, or other precision-required tasks.

Setting Up Your Laser Tape Device

Before you begin using your measurement device, it’s crucial to ensure that it is properly configured. This process involves a few essential steps that will prepare the equipment for accurate and reliable performance.

First, place the device on a stable surface to prevent any movement during setup. Verify that the power source is correctly connected and the device is turned on. Make sure to check the battery level or power indicators to confirm that the device has sufficient energy for operation.

Next, calibrate the device by following the manufacturer’s instructions, which usually involve adjusting settings to align with standard measurements. Consult the user guide for specific calibration procedures tailored to your model.

Finally, familiarize yourself with the controls and display functions. Testing a few measurements will help you confirm that everything is functioning correctly. Performing a test run ensures that your device is ready for precise usage.

How to Calibrate for Accurate Measurements

Ensuring precise readings requires proper adjustment of your measurement device. Calibration is a crucial step to confirm that the tool provides accurate results. By following the right procedures, you can maintain the reliability of your measurements.

Begin by setting up the device on a stable surface. Use a known reference to test its accuracy. Compare the device’s readings with the reference values to determine any discrepancies.

Adjust the device settings according to the manufacturer’s guidelines. Make sure to perform calibration in an environment free from disturbances that could affect the results. Regular checks and adjustments will help maintain accuracy over time.

| Step | Action |

|---|---|

| 1 | Place the device on a stable surface. |

| 2 | Use a known reference for testing. |

| 3 | Compare readings with reference values. |

| 4 | Adjust settings according to guidelines. |

| 5 | Perform calibration in a disturbance-free environment. |

Common Applications and Uses

Measurement tools offer versatile solutions for various tasks, enhancing precision and efficiency in numerous settings. Their utility spans a broad range of activities, from simple home projects to complex professional tasks.

- Home Renovations: Ideal for aligning fixtures, ensuring straight lines, and measuring distances accurately during home improvement projects.

- Construction: Useful for verifying straightness and measuring distances in construction sites, helping professionals achieve precise results.

- Interior Design: Assists in planning layouts, ensuring that furniture and decor are aligned perfectly within a space.

- Engineering: Essential for setting up equipment, aligning components, and conducting measurements in various engineering tasks.

- DIY Projects: Provides accuracy for personal projects such as building shelves, hanging artwork, or installing fixtures.

Maintaining and Troubleshooting Issues

Proper upkeep and problem-solving are crucial for ensuring optimal performance of your measurement device. Regular maintenance helps in identifying potential issues before they escalate, while effective troubleshooting can resolve any problems that arise during use. This section provides guidance on keeping your device in good condition and addressing common malfunctions.

Routine Maintenance: To keep your device functioning accurately, clean the components regularly and store it in a dry, dust-free environment. Ensure the batteries are charged and replace them as needed. Check for any signs of wear or damage and address them promptly to prevent further issues.

Troubleshooting Common Problems: If you encounter inaccuracies or malfunctioning, first verify that the device is correctly calibrated. Ensure there are no obstructions affecting its operation. If the problem persists, consult the user guide for specific troubleshooting steps or seek professional assistance if necessary.

Safety Precautions and Best Practices

When working with precision measuring tools, ensuring safety and proper usage is essential. Following correct practices not only safeguards you but also enhances the accuracy and longevity of the equipment. It is important to understand the potential hazards associated with these tools and adhere to recommended procedures to mitigate risks.

Always prioritize safety by wearing appropriate protective gear, such as safety glasses and gloves, to prevent injuries. Ensure that the work area is clean and free from any obstructions that could cause accidents.

Regular maintenance and calibration of the equipment are crucial for optimal performance. Be sure to follow the manufacturer’s guidelines for routine checks and servicing to maintain accuracy.

Additionally, avoid using the tool in adverse conditions, such as extreme temperatures or high humidity, as these factors can affect its functionality. Store the tool in a safe, dry place when not in use to prevent damage.