When it comes to mastering the operation of advanced analytical instruments, having a clear and comprehensive reference is crucial. This guide serves as a fundamental resource for users seeking to effectively utilize a sophisticated liquid chromatograph system. Designed to enhance your technical proficiency, it offers detailed insights into the setup, calibration, and maintenance of this essential laboratory equipment.

Within these pages, you will discover step-by-step instructions and practical advice aimed at ensuring optimal performance and accuracy. Whether you are setting up the system for the first time or troubleshooting issues, this guide provides valuable information to support your daily laboratory activities. By following the outlined procedures, you can maximize the efficiency and reliability of your analytical processes.

Each section is carefully structured to address specific aspects of operating the equipment, from initial configuration to routine upkeep. This organized approach not only simplifies complex tasks but also helps in achieving consistent and reproducible results in your experiments. Embrace this guide as your go-to reference for all matters related to your liquid chromatograph.

Overview of Shimadzu LC-20AD System

The liquid chromatography system represents a sophisticated and versatile tool designed to enhance the precision and efficiency of chemical analysis. This analytical equipment is engineered to separate, identify, and quantify components within a mixture with high accuracy and reliability.

Featuring a range of advanced technologies, this system ensures that analytical procedures are both accurate and reproducible. The high-performance liquid chromatography (HPLC) unit integrates various components such as a pump, injector, and detector to manage and analyze complex samples effectively.

Each component plays a crucial role in the overall functionality of the system. The pump delivers a constant flow of mobile phase, the injector introduces samples into the flow stream, and the detector monitors the separated compounds, providing valuable data for analysis.

Overall, the liquid chromatography system offers a reliable and efficient solution for a wide range of analytical tasks, making it an essential instrument in many research and quality control laboratories.

Installation and Setup Process

Setting up a liquid chromatograph involves several critical steps to ensure its optimal performance. Proper installation and configuration are essential to achieve accurate and reliable results from your analytical equipment.

Follow these guidelines for a smooth installation and setup process:

- Unboxing and Inspection: Carefully remove the equipment from its packaging and check for any signs of damage. Ensure that all components and accessories are present as listed in the included parts list.

- Location and Placement: Choose a stable, level surface to place the device. Ensure the location is clean, well-ventilated, and away from direct sunlight and sources of vibration.

- Power Supply: Connect the unit to a suitable power outlet that matches the specified voltage and frequency requirements. Ensure that the power cord is properly plugged in and secure.

- Connecting Tubing and Samples: Attach the necessary tubing to the designated ports according to the instructions provided. Ensure that all connections are tight and free of leaks.

- Initial Setup: Turn on the device and follow the on-screen prompts or instructions to configure initial settings. This may include calibrating the system, setting up data acquisition parameters, and running a preliminary test.

By adhering to these steps, you will ensure that your liquid chromatograph is set up correctly and ready for precise analytical tasks. Regular maintenance and adherence to operational guidelines will help in sustaining its performance over time.

Basic Operations and Controls

This section provides an overview of the fundamental procedures and control elements necessary for operating the liquid chromatography system. Understanding these basics will enable efficient use and maintenance of the equipment, ensuring accurate and reliable analytical results.

Starting and Stopping the System

- Powering On: Locate the power button on the front panel. Press and hold it for a few seconds until the system powers up and initializes.

- Powering Off: To shut down the system, press and hold the power button until the system completely turns off. Ensure all processes are finished before powering down.

Operating the Controls

- Flow Rate Adjustment: Use the flow rate control knob to set the desired flow speed for the mobile phase. Accurate flow rate setting is crucial for precise separation of compounds.

- Injection Volume: Adjust the injection volume using the designated control panel. Ensure the correct volume is selected based on the analysis requirements.

- Detector Settings: Access the detector settings to calibrate and adjust sensitivity. This step is essential for optimal detection of analytes.

- Program Management: Utilize the system’s interface to create, modify, and run analytical programs. Programming specific methods can streamline repetitive tasks and ensure consistent results.

Maintenance and Troubleshooting Tips

Proper upkeep and addressing issues promptly are crucial for ensuring the reliable performance of your chromatographic equipment. Regular maintenance not only extends the lifespan of the system but also helps prevent unexpected malfunctions that could impact the quality of your results. This section provides practical advice on how to maintain the system effectively and troubleshoot common problems that may arise during its operation.

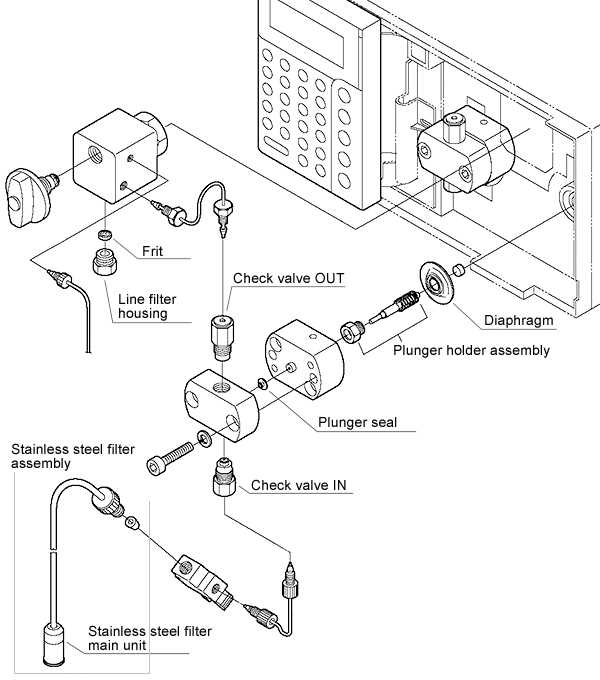

Start with routine cleaning and inspection of key components to prevent contamination and ensure smooth operation. Check for leaks, inspect seals and connections, and replace worn parts as needed. Regularly verify that all connections are secure and that there are no obstructions in the flow paths. Pay close attention to the condition of the pump, detector, and injector, as these are critical to the system’s performance.

If you encounter issues such as inconsistent results, fluctuating pressure, or unexpected error messages, consult the troubleshooting guidelines for potential solutions. Common problems might include air bubbles in the system, blockages, or calibration errors. Systematic checks and adjustments can often resolve these issues quickly. Ensure that software settings are correctly configured and up-to-date, as software glitches can sometimes contribute to operational difficulties.

Adhering to these maintenance and troubleshooting practices will help keep your chromatographic system running smoothly and efficiently, minimizing downtime and ensuring accurate analytical results.

Understanding Analytical Parameters

Grasping the concept of analytical parameters is crucial for optimizing the performance of any liquid chromatography system. These parameters dictate the precision and accuracy of the separation process, influencing the quality of the results obtained. By adjusting these settings appropriately, one can enhance the efficiency and reliability of the analytical method employed.

Key factors such as flow rate, column temperature, and detection wavelength play significant roles in the separation and quantification of compounds. The flow rate affects the interaction between the mobile and stationary phases, while the column temperature can influence the retention times and resolution of the analytes. Additionally, the detection wavelength determines the sensitivity and specificity of the measurements. Understanding and fine-tuning these parameters are essential for achieving optimal performance and obtaining accurate analytical data.

Safety and Compliance Guidelines

Ensuring a safe and compliant working environment is crucial for the proper functioning and longevity of any scientific equipment. This section outlines the essential practices and standards to follow to maintain safety and adhere to regulatory requirements while operating and maintaining analytical instruments.

General Safety Precautions

- Always read and understand the user documentation before operating the equipment.

- Ensure that the equipment is installed in a clean, dry, and well-ventilated area to prevent damage and ensure proper functioning.

- Wear appropriate personal protective equipment (PPE), such as gloves and safety goggles, when handling chemicals or operating the device.

- Keep all safety shields and covers in place while the equipment is in operation.

- Do not bypass or disable any safety mechanisms provided with the device.

- Immediately report any malfunctions or irregularities to a qualified technician for repair.

Regulatory Compliance

- Ensure that the equipment is compliant with local, national, and international regulations relevant to your field.

- Maintain accurate records of calibration, maintenance, and service to comply with regulatory standards.

- Follow proper disposal procedures for any waste materials generated during operation or maintenance.

- Regularly review and update safety protocols in accordance with the latest guidelines and regulations.

- Participate in training programs to stay informed about safety practices and compliance requirements.