In the realm of modern technology, understanding the operation and capabilities of sophisticated control units is crucial. These devices are designed to optimize performance and enhance efficiency in various applications. This guide aims to provide a thorough exploration of one such advanced drive system, focusing on its functions, features, and operational nuances.

The document is intended to be an essential resource for users seeking to grasp the intricacies of these control mechanisms. It will cover fundamental concepts, detailed procedural instructions, and troubleshooting tips to ensure users can maximize the potential of their equipment. Through clear explanations and practical advice, this guide will serve as a valuable tool for both novices and experienced professionals alike.

With an emphasis on clarity and practical application, this resource will help users navigate the complexities of their drive systems. By the end of this guide, readers will have a solid understanding of how to effectively operate and maintain their devices, ensuring optimal performance and reliability in their operations.

Understanding the FR-D700 Inverter

Grasping the operation of a variable frequency drive is essential for optimizing the performance of electrical motors and systems. This guide delves into the core principles and features of a specific drive model, shedding light on its capabilities and functionalities. By examining its components and settings, users can achieve more efficient control over their machinery and processes.

At its essence, this device regulates the speed and torque of electric motors by adjusting the frequency and voltage of the electrical supply. It plays a crucial role in applications requiring precise control, offering enhancements in both performance and energy consumption. Through understanding its operational parameters and configuration options, users can tailor the system to meet specific needs and improve overall efficiency.

Familiarity with the drive’s interface, programming options, and troubleshooting methods equips users with the knowledge to leverage its full potential. This leads to not only better operational control but also increased reliability and reduced operational costs.

Key Features and Specifications

This section provides a detailed overview of the essential characteristics and technical parameters of the device, highlighting its capabilities and performance metrics. Understanding these attributes will help you make the most of its functionalities and ensure it meets your operational requirements.

| Feature | Description |

|---|---|

| Power Output | Delivers a range of output levels suitable for various industrial applications, ensuring flexibility and efficiency in performance. |

| Control Modes | Offers multiple control modes including vector control and scalar control, providing versatility in managing different types of loads. |

| Frequency Range | Supports a broad frequency range, allowing for precise speed control and adaptation to different operational speeds. |

| Communication Interfaces | Equipped with standard communication ports such as RS-485, enabling seamless integration with other systems and devices. |

| Protection Features | Includes various protection mechanisms against overvoltage, overheating, and short circuits to ensure reliability and longevity. |

| Size and Weight | Compact design with lightweight construction facilitates easy installation and space-saving benefits. |

| Efficiency | High efficiency rating ensures optimal energy usage and reduces operational costs over time. |

| Environmental Ratings | Designed to operate effectively in a range of environmental conditions, with resistance to dust and moisture for enhanced durability. |

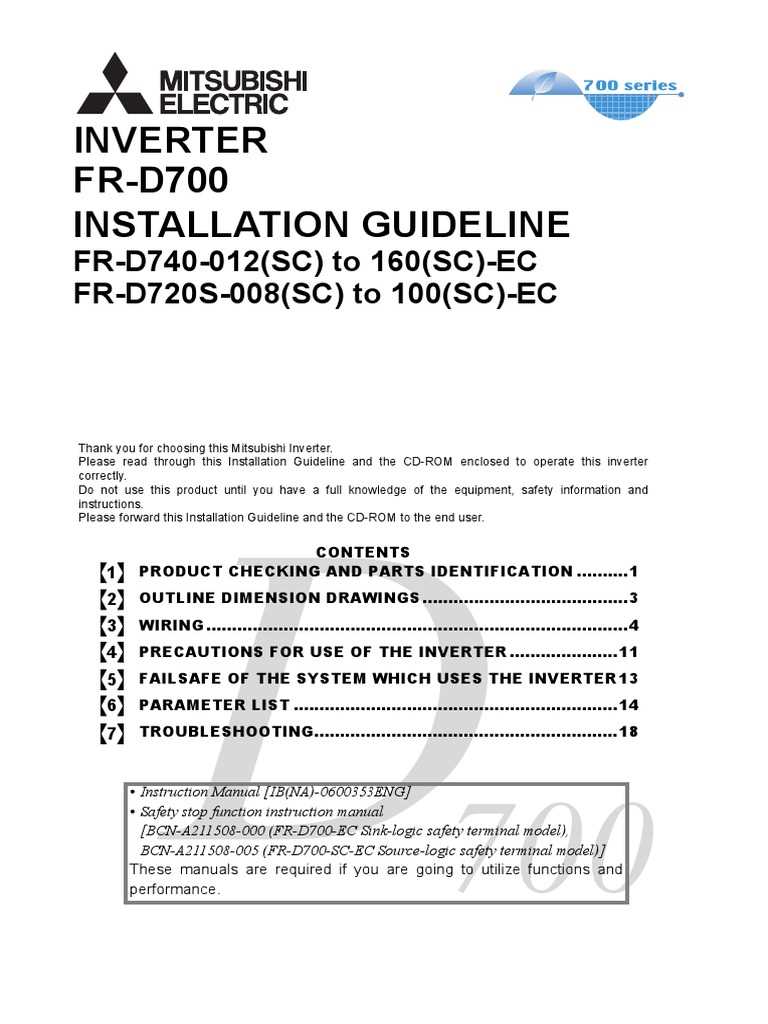

Step-by-Step Installation Guide

Proper setup of your equipment is essential for optimal performance and longevity. This guide provides a comprehensive walkthrough for installing your device, ensuring all components are correctly connected and configured. Follow each step carefully to achieve a successful installation.

Preparation

- Ensure you have all necessary tools and components ready before starting.

- Review the provided documentation to familiarize yourself with the parts and their functions.

- Select an appropriate location for installation that meets the device’s requirements.

- Verify that the power supply meets the specifications for the equipment.

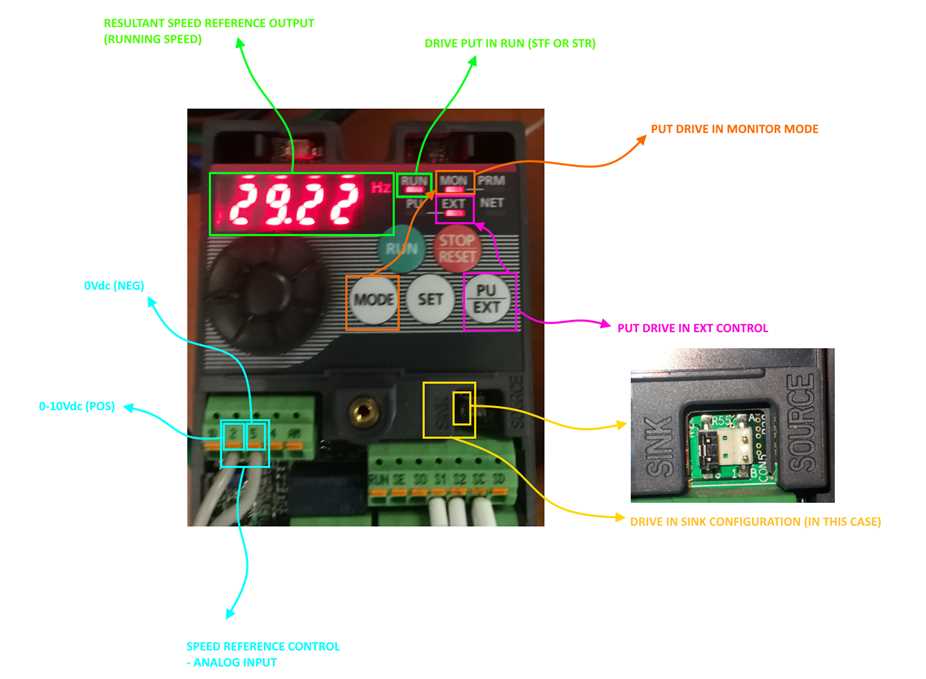

Installation Steps

- Begin by mounting the device securely to the chosen location. Use the provided brackets and screws for stability.

- Connect the power cables according to the instructions. Ensure all connections are tight and secure.

- Link the necessary input and output lines as specified. Double-check that each connection is properly aligned and fixed.

- Configure the device settings as required for your application. Refer to the setup options detailed in the documentation.

- Perform a test run to ensure everything operates correctly. Observe for any irregularities and address them as needed.

Following these steps will help you set up your equipment efficiently and correctly. For any issues encountered during installation, consult the troubleshooting section or seek professional assistance.

Programming and Configuration Tips

Mastering the settings and adjustments of your drive system can significantly enhance its performance and efficiency. Properly configuring the various parameters allows you to tailor the operation to meet specific requirements, ensuring optimal functionality and longevity. This section offers valuable insights into effectively programming and setting up your equipment for various applications.

Understanding Parameter Basics

Before diving into advanced configurations, it’s crucial to grasp the fundamental parameters and their impact on operation. Familiarize yourself with the basic settings such as speed limits, acceleration, and deceleration. These foundational elements set the stage for more complex adjustments and help prevent common issues during setup.

Customizing for Specific Applications

To achieve the best results, customize the settings according to the unique needs of your application. Pay close attention to factors like load characteristics and operational conditions. Adjusting parameters such as torque limits and control modes can optimize performance and energy efficiency based on your specific usage scenario.

Troubleshooting Common Issues

When operating complex electronic devices, encountering problems is not uncommon. Identifying and resolving these issues can enhance performance and extend the lifespan of the equipment. This section will guide you through common challenges and provide steps to rectify them effectively.

- Device Fails to Power On:

- Ensure that the power source is functioning correctly. Check the power cord and connections for any damage or loose fittings.

- Verify that the device’s power switch is turned on and that all circuit breakers or fuses are intact.

- Inconsistent or Unstable Output:

- Inspect all input and output connections for secure attachment and signs of wear or damage.

- Review the configuration settings to ensure they align with operational requirements.

- Look for any error messages or warning indicators on the display panel that could provide additional insights.

- Overheating Issues:

- Ensure that the device is placed in a well-ventilated area to prevent overheating.

- Check for any obstructions around cooling vents or fans that might impede airflow.

- Clean the device periodically to remove dust and debris that could affect cooling efficiency.

- Unusual Noises:

- Listen for any unusual sounds coming from the device and check if they correlate with any visible issues or malfunctions.

- Inspect internal components for loose parts or signs of wear that may contribute to noise generation.

- Inaccurate Readings or Performance:

- Confirm that calibration settings are correct and recalibrate if necessary.

- Ensure that all connected components are compatible and functioning properly.

- Consult the troubleshooting guide for specific error codes or performance issues related to the device.

Maintenance and Safety Recommendations

Proper upkeep and adherence to safety protocols are crucial for the longevity and efficient operation of your equipment. Regular maintenance ensures that the device operates smoothly and minimizes the risk of unexpected failures. Following these guidelines will help you maintain peak performance and ensure user safety.

- Regular Inspections: Periodically check the device for any signs of wear or damage. Look for loose connections, frayed wires, and other potential issues that could affect performance.

- Cleaning: Keep the equipment clean and free from dust and debris. Use a soft, dry cloth to wipe down surfaces. Avoid using liquids or abrasive materials that could damage components.

- Ventilation: Ensure that the equipment is placed in a well-ventilated area. Proper airflow is essential to prevent overheating and ensure efficient operation.

- Electrical Safety: Verify that all electrical connections are secure and insulated. Avoid overloading circuits and use appropriate fuses or circuit breakers as recommended.

- Software Updates: If applicable, keep any associated software or firmware up to date. This can enhance functionality and address any potential vulnerabilities.

Adhering to these maintenance and safety practices will help prolong the life of your equipment and ensure a safe working environment. Always refer to the specific guidelines provided by the manufacturer for detailed instructions and recommendations.

Frequently Asked Questions

In this section, we address common queries that users often have regarding their devices. These questions cover a range of topics including installation, troubleshooting, and optimal usage practices. If you have specific concerns or issues, you may find the answers you need here to help enhance your experience and resolve any problems effectively.

Q: How do I properly install the equipment?

A: Ensure that you follow the installation guidelines provided in the product documentation. It is important to adhere to the recommended settings and connections to ensure optimal performance and safety.

Q: What should I do if the device is not powering on?

A: Check the power source and ensure that all connections are secure. Verify that the power switch is in the ‘on’ position. If the issue persists, consult the troubleshooting section of the guide for further assistance.

Q: How can I adjust the settings for optimal performance?

A: Refer to the configuration options outlined in the user guide. Adjust settings according to your specific requirements and operational needs. Regularly review and update settings to maintain efficiency and performance.

Q: What are the common issues and how can I resolve them?

A: Common issues may include connectivity problems, performance inconsistencies, or error messages. Refer to the troubleshooting section for detailed solutions to these common problems. Ensuring regular maintenance and correct usage can also help in preventing such issues.

Q: Where can I find additional support if needed?

A: For further assistance, consult the support section of the product’s website or contact customer service. Many resources are available online, including FAQs, user forums, and direct support options.