Understanding the correct setup and operation of devices is crucial for ensuring they perform optimally and safely. This guide offers detailed information on how to effectively configure and utilize a widely-used piece of equipment, providing step-by-step instructions to maximize its functionality and lifespan.

Whether you’re a first-time user or need a refresher, this resource covers essential aspects of installation, programming, and troubleshooting. With clear explanations and tips, you’ll gain confidence in handling the device, allowing you to achieve desired results with ease.

Explore the details on how to fine-tune the settings, and ensure your device operates precisely according to your needs. This guide will help you navigate the various features, making sure you can take full advantage of its capabilities.

Understanding the Wiring Configuration

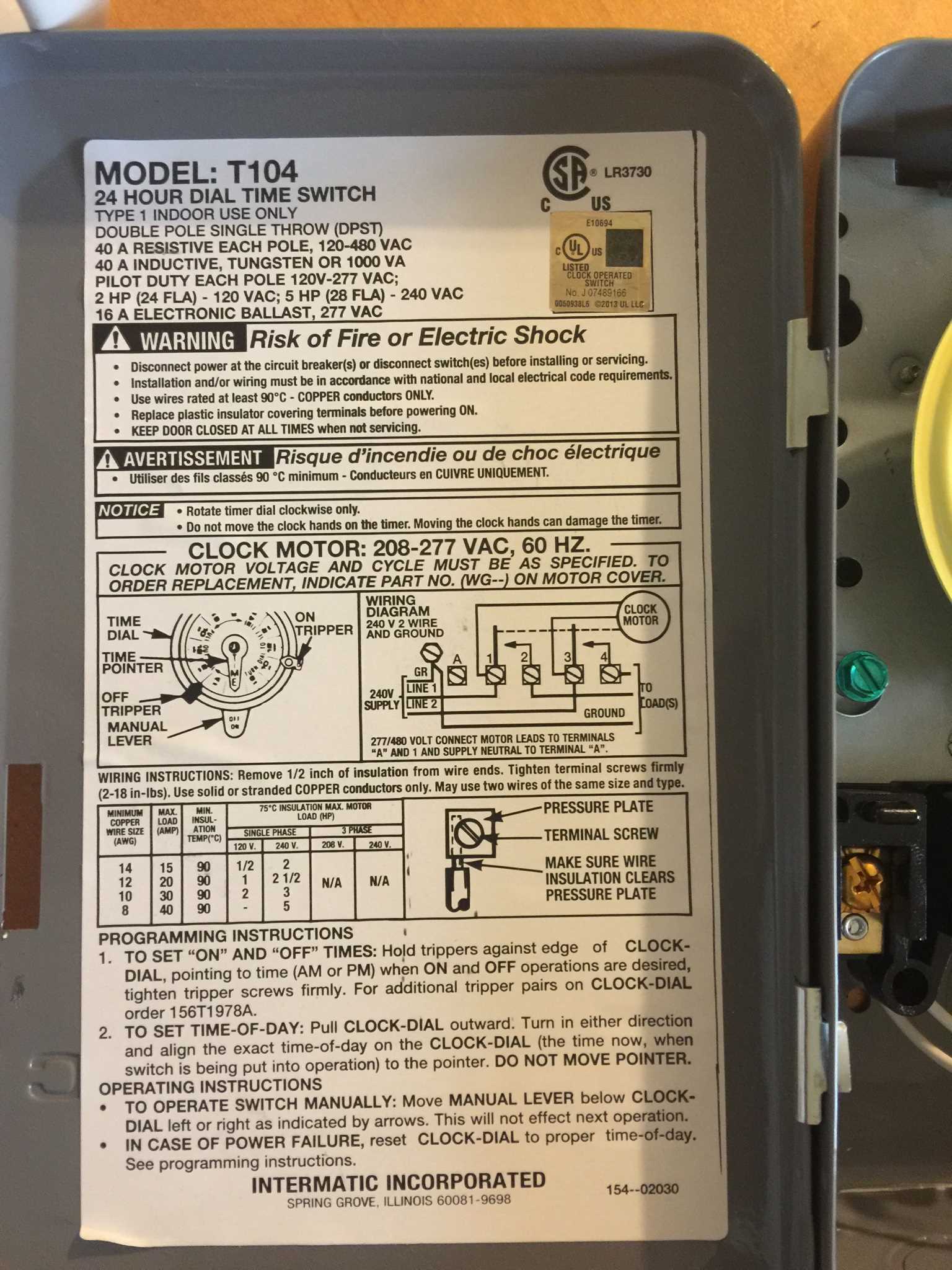

When dealing with electrical installations, correctly identifying and connecting the wiring is crucial to ensure the safe and efficient operation of any device. Proper wiring ensures that the system functions as intended, reducing the risk of short circuits, power overloads, and other potential hazards. This section will guide you through the essential aspects of wiring configuration, focusing on the general principles and key considerations for secure and effective setup.

Identifying the Terminals

The first step in the wiring process involves recognizing the different terminals present in the device. Each terminal serves a specific purpose, and it is vital to understand their roles to connect the wires accurately. Typically, terminals are categorized into input and output sections. The input terminals receive the electrical power, while the output terminals distribute power to the connected loads. Ensure that you match each wire to its corresponding terminal according to the power supply and load requirements.

Connecting the Wires

Once you have identified the terminals, proceed to connect the wires. Begin by ensuring that the power is turned off to avoid any electrical shock. Strip the insulation from the ends of the wires to expose the metal conductors. Carefully insert the exposed wire into the correct terminal, ensuring a secure connection. Tighten the terminal screw to hold the wire firmly in place. Repeat this process for all required connections, double-checking that each wire is correctly routed and securely fastened.

Important: Always verify that the connections are secure and that there is no contact between exposed wires, as this can lead to short circuits or other electrical failures. Following these steps will help ensure a safe and efficient setup.

Setting Up the Timer for Daily Use

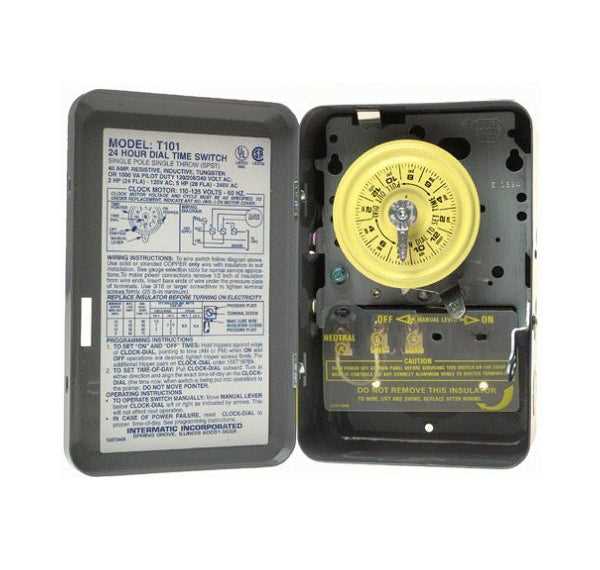

To ensure your timer operates efficiently, it’s essential to configure it according to your daily needs. This process involves adjusting settings that control when your connected devices will automatically turn on and off, ensuring a consistent schedule.

Configuring the Timer Settings

Begin by identifying the specific times you want your devices to activate and deactivate. Once you have determined these periods, follow these steps to set the schedule:

| Step | Action | Details |

|---|---|---|

| 1 | Determine On/Off Times | Decide the exact time you want your devices to turn on and off each day. |

| 2 | Set the On Time | Rotate the dial to align the time indicator with your desired start time. |

| 3 | Set the Off Time | Adjust the dial again to set the time when the devices should turn off. |

| 4 | Secure the Settings | Ensure that all settings are locked in place by pressing the appropriate lever or button. |

Testing the Configuration

After setting up, it’s advisable to test the timer to confirm that it activates and deactivates at the intended times. This ensures that your schedule is correctly implemented and your devices will function as expected.

Troubleshooting Common Issues with T101R

When working with mechanical timers, occasional issues may arise that disrupt normal operation. Identifying and resolving these problems ensures reliable performance and extends the lifespan of the device. Below are some common challenges users may encounter, along with practical solutions to address them effectively.

Timer Not Advancing: If the timer dial is not progressing, check if the power supply is consistent. Ensure the connections are secure and the unit is receiving uninterrupted electricity. If the issue persists, examine the motor for any signs of wear or damage that could hinder its operation.

Inaccurate Timekeeping: Should the timer fail to maintain accurate time, verify that it is set correctly. In some cases, debris or dirt may obstruct the gears, causing delays. Cleaning the unit and resetting the time may resolve the problem.

Skipping On/Off Cycles: If the timer is missing scheduled on/off events, inspect the trippers. Make sure they are correctly positioned and not worn out. Replacing them might be necessary if they are not triggering the switch as expected.

Unresponsive Switch: A timer switch that does not respond to manual overrides might indicate internal damage or a malfunctioning switch mechanism. Testing the switch with a multimeter can help determine if it needs replacement.

By systematically addressing these issues, users can maintain optimal functionality of their mechanical timer and ensure it operates as intended.

Maintenance Tips for Prolonged Lifespan

Ensuring the longevity of any mechanical or electrical device requires regular care and attention. Consistent upkeep not only extends the life of the equipment but also enhances its efficiency and safety over time. Below are key practices that can help maintain your device in optimal condition.

Regular Cleaning

Dust and debris can accumulate over time, leading to potential malfunctions. It’s essential to keep the device clean by gently wiping it down with a dry, soft cloth. Pay special attention to any moving parts and electrical contacts, as these areas are particularly prone to buildup. Regular cleaning helps prevent obstruction and ensures smooth operation.

Inspect and Replace Parts

Periodically inspect the device for any signs of wear or damage. Key components like screws, terminals, and connectors should be checked to ensure they are secure and free from corrosion. If any part appears to be worn out or compromised, replacing it promptly can prevent larger issues down the line. Timely replacements of minor parts are crucial for avoiding costly repairs.

Following these maintenance tips will significantly contribute to the durability and performance of your equipment. Consistent care allows you to maximize the utility of the device and avoid unexpected breakdowns.

Exploring Advanced Features and Options

Delving deeper into the functionality of your device, you’ll find several sophisticated features designed to enhance its usability and adaptability. These options allow for a more tailored experience, catering to specific needs and preferences. This section will guide you through these advanced settings, ensuring that you can fully leverage the capabilities of your equipment.

Customization of Timing Intervals

The device offers flexibility in setting custom time intervals, allowing for a precise schedule that fits your requirements. Whether you need shorter or longer durations, these adjustments can be easily configured to match your specific operational needs. This feature is particularly useful for applications where timing accuracy is critical.

Manual Override and Control Options

One of the standout features is the manual override, providing the ability to temporarily bypass the pre-set schedule without altering the existing configuration. This function is ideal for situations requiring immediate adjustments, offering full control at your fingertips. Below is a summary of the available options:

| Feature | Description |

|---|---|

| Manual Override | Enables immediate on/off control, bypassing the programmed schedule. |

| Custom Timing | Adjustable intervals for precise timing needs. |

| Permanent Override | Allows for a continuous override of the schedule until reset. |