Whether you’re maintaining a pristine garden or tackling a large lawn, understanding the proper handling of your cutting tool is crucial for optimal performance and safety. This section offers comprehensive guidance to help you get the most out of your device. From assembly to daily upkeep, each step is designed to ensure efficient use and longevity of your equipment.

Within this guide, you will discover detailed instructions and helpful tips for operating your trimmer effectively. Learn about the necessary preparations before starting your work, the recommended procedures for regular maintenance, and troubleshooting techniques to address common issues. With the right knowledge, you can enhance both the efficiency and lifespan of your tool.

By familiarizing yourself with these essential practices, you ensure not only the smooth operation of your equipment but also a safer working environment. Whether you are a novice or an experienced user, this resource is crafted to provide clear, practical advice tailored to your needs.

Overview of Echo SRM 225

This section provides an in-depth look at a versatile tool designed for garden maintenance. Engineered to offer powerful performance, this device stands out due to its combination of functionality and ease of use. Ideal for both professional landscapers and homeowners, it boasts features that cater to various trimming needs.

Key Features

- Engine Power: Equipped with a robust engine that delivers consistent power, ensuring efficient cutting and trimming.

- Ergonomic Design: Features a comfortable grip and adjustable components to enhance user comfort and control during operation.

- Durability: Constructed from high-quality materials to withstand rigorous use and environmental conditions.

- Versatility: Includes attachments and settings that allow it to handle different types of vegetation with ease.

Maintenance and Care

To ensure optimal performance and longevity, regular maintenance is essential. Key tasks include:

- Routine Cleaning: Keep the tool clean by removing debris and checking for any signs of wear.

- Engine Care: Follow recommended procedures for fuel and oil changes to maintain engine efficiency.

- Inspection: Regularly inspect the equipment for any loose or damaged parts and address issues promptly.

By adhering to these maintenance practices, users can enjoy reliable performance and extend the lifespan of their tool.

Understanding Key Features and Specifications

In order to fully appreciate the performance and utility of a tool, it is crucial to grasp its fundamental attributes and technical details. This section aims to shed light on the essential elements that define the capabilities and functionality of the equipment in question.

Power Output is a critical factor that influences the effectiveness of the tool. The engine’s horsepower and displacement give an idea of its capacity to handle various tasks and its overall efficiency. Higher power often translates to better performance in demanding conditions.

Cutting Width is another important specification. This dimension determines the extent of material that can be processed in a single pass, impacting the speed and coverage of your work. A wider cutting width can significantly reduce the time required for large-scale projects.

Fuel Type and Capacity are also essential aspects. The type of fuel required affects the operational costs and convenience, while the fuel tank size influences the duration of continuous operation before refueling is needed.

Weight of the equipment is an important consideration for ease of use and maneuverability. Lighter tools are generally easier to handle and reduce user fatigue during extended periods of operation.

Safety Features play a vital role in ensuring safe operation. Elements such as automatic shut-off mechanisms, safety guards, and ergonomic design contribute to reducing the risk of accidents and enhancing user protection.

By understanding these core features and specifications, users can make informed decisions and optimize their use of the equipment for various applications.

Step-by-Step Operating Instructions

This section is designed to guide you through the process of using your equipment efficiently and safely. It outlines the essential steps to ensure proper handling and operation, helping you achieve optimal performance and avoid potential issues. Follow these directions carefully to make the most of your tool.

Preparation Before Use

Before starting your equipment, it’s important to ensure that everything is in proper working condition. Follow these preliminary steps:

| Step | Action |

|---|---|

| 1 | Inspect the equipment for any visible damage or wear. |

| 2 | Check the fuel or power source to ensure it is full and properly connected. |

| 3 | Verify that all safety guards and components are securely in place. |

Operating the Equipment

Once preparations are complete, follow these steps to operate your equipment:

| Step | Action |

|---|---|

| 1 | Turn on the power or start the engine according to the guidelines. |

| 2 | Adjust settings or controls as needed for the task at hand. |

| 3 | Operate the equipment with a steady and controlled motion. |

Maintenance Tips for Longevity

Proper upkeep of your equipment is essential to ensure its durability and optimal performance over time. Regular care and attention can significantly extend the lifespan of your device and maintain its efficiency. By adhering to a few simple maintenance practices, you can avoid common issues and enhance the reliability of your tool.

- Regular Cleaning: Keep your equipment clean by removing dirt, debris, and residue after each use. This prevents buildup that can cause wear and tear on internal components.

- Check and Replace Filters: Regularly inspect and replace air and fuel filters as needed to maintain proper airflow and engine performance.

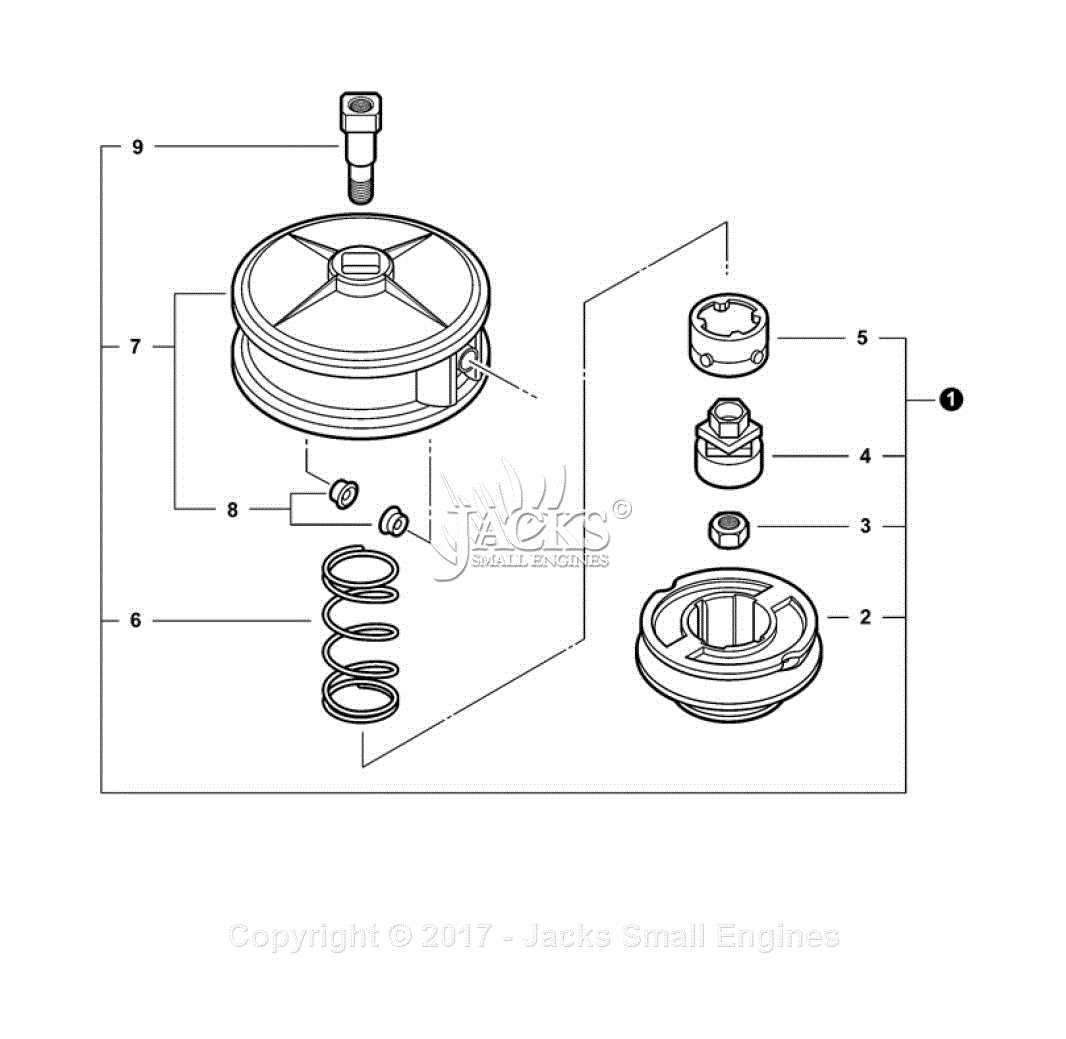

- Inspect and Tighten Bolts: Periodically check all bolts and fasteners to ensure they are securely tightened. Loose components can lead to mechanical failures.

- Oil and Lubrication: Ensure that moving parts are well-lubricated. Use the recommended type of oil and follow the manufacturer’s guidelines for lubrication intervals.

- Sharpen Blades: If your device uses blades, keep them sharp for efficient operation. Dull blades can strain the engine and reduce performance.

- Store Properly: When not in use, store your equipment in a dry, sheltered area to protect it from environmental elements that can cause corrosion or damage.

By following these maintenance tips, you can ensure that your equipment remains in excellent condition and continues to perform effectively for many years to come.

Common Troubleshooting Solutions

When operating a garden tool, encountering issues is not uncommon. This section provides guidance on addressing frequent problems that users might face, ensuring smooth and efficient performance of your equipment. By following these solutions, you can resolve typical malfunctions and maintain optimal functioning.

- Engine Won’t Start:

- Check if the fuel tank has adequate gasoline and that it is properly mixed if required.

- Ensure that the fuel lines are not clogged or damaged.

- Inspect the spark plug for wear or carbon buildup, and replace it if necessary.

- Confirm that the on/off switch is set to the correct position.

- Tool Runs Poorly or Unevenly:

- Examine the air filter and clean or replace it if it’s dirty or clogged.

- Check the carburetor for proper adjustment and clean it if needed.

- Inspect the condition of the spark plug and replace it if it shows signs of wear.

- Ensure that the throttle is functioning correctly and that there are no obstructions.

- Excessive Vibration:

- Check for loose or damaged parts and tighten or replace them as needed.

- Ensure that the cutting head is securely attached and not worn out.

- Inspect the equipment for any imbalance in the blades or other components.

- Fuel Leaks:

- Inspect the fuel lines and connections for any cracks or damage.

- Ensure that the fuel tank cap is tightly secured.

- Replace any damaged or worn fuel lines and fittings.

By addressing these common issues, you can extend the life of your equipment and ensure it operates smoothly. If problems persist despite these troubleshooting steps, consult a professional for further assistance.

Safety Precautions and Guidelines

When operating any piece of machinery, it is crucial to adhere to established safety measures to prevent accidents and ensure smooth functionality. Understanding and following these precautions helps safeguard both the user and the equipment. This section outlines essential safety protocols to observe while using such tools.

- Always read and understand the entire user guide before starting the equipment.

- Ensure that you wear appropriate protective gear, such as gloves, goggles, and ear protection, to minimize risks.

- Inspect the equipment thoroughly before each use to confirm that all parts are in good condition and properly assembled.

- Keep the work area clean and free of any debris that could pose a hazard.

- Do not operate the machinery under the influence of alcohol, drugs, or any substances that could impair your judgment.

- Be cautious when handling fuel or other flammable materials. Store them in a safe location away from direct sunlight or heat sources.

- Ensure that the equipment is turned off and disconnected from the power source when performing maintenance or making adjustments.

- Keep children and pets away from the work area to prevent accidental injuries.

Following these guidelines will contribute to a safer working environment and enhance the longevity of your equipment. Always prioritize safety to ensure both effective operation and personal protection.