Discover the essential steps and practices for seamlessly managing your sewing equipment. This guide provides clear instructions and valuable insights into utilizing your machine efficiently, ensuring you achieve the best results in your sewing projects. Whether you’re a beginner or an experienced user, the following sections are designed to help you understand the key functionalities and optimize the performance of your device.

With a focus on user-friendly tips and detailed explanations, this guide aims to enhance your experience with your sewing equipment. You’ll find a wealth of information covering everything from basic setup to advanced techniques. Explore the various features and learn how to maintain your machine for long-term use.

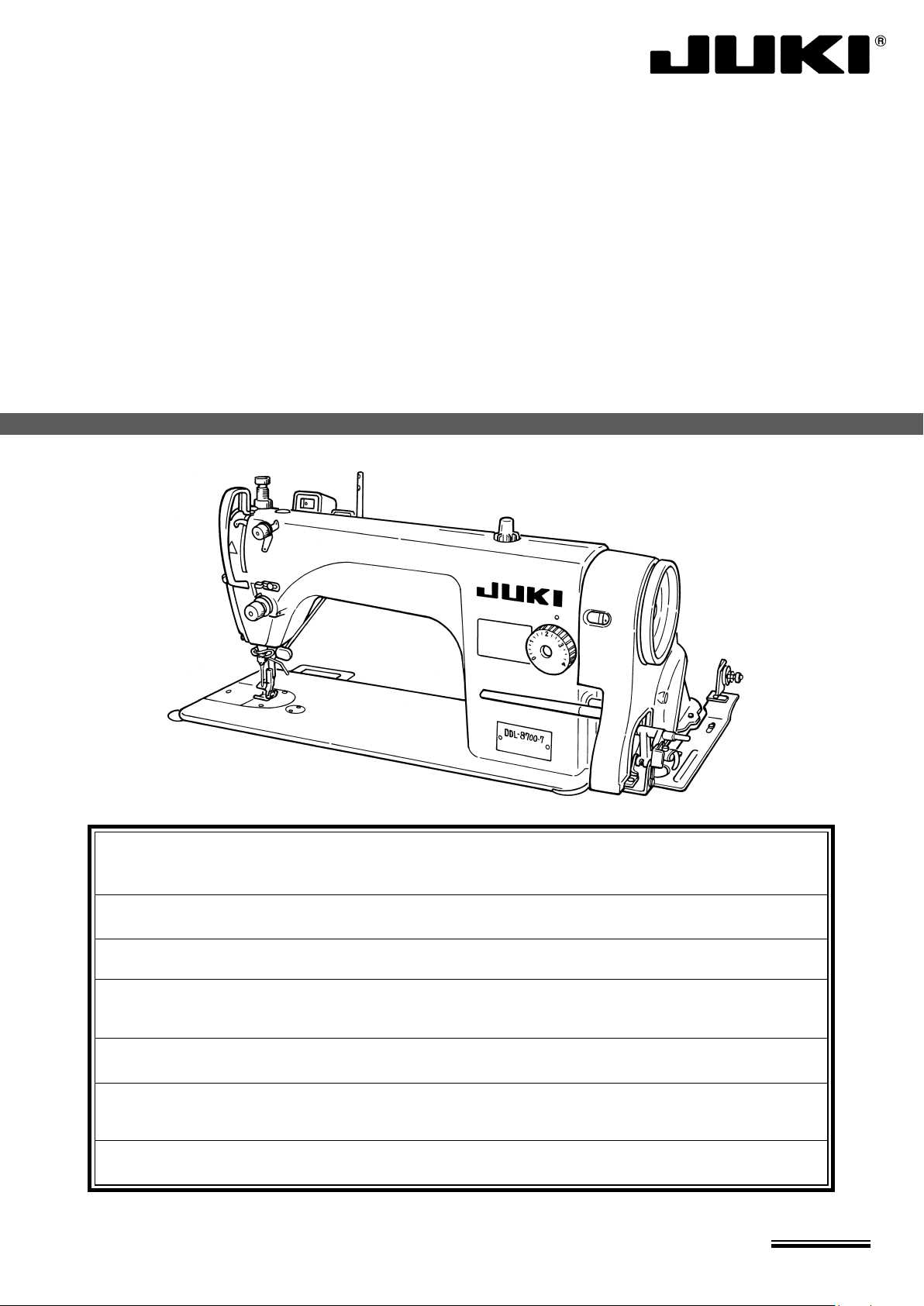

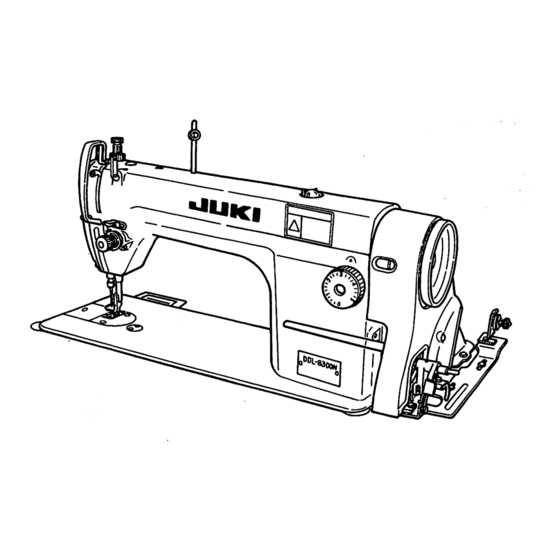

Overview of the Sewing Machine Model

This section provides a comprehensive

Key Features and Capabilities

This section highlights the advanced attributes and functionalities of the equipment, focusing on the innovative aspects that make it a reliable choice for various tasks. These elements ensure efficiency and precision in operation, making the machine suitable for both professional and personal use.

The device is equipped with features that enhance performance, including high-speed operation and consistent quality results. Its ergonomic design is tailored for ease of use, reducing fatigue during extended sessions. Additionally, it offers a range of customizable settings, allowing users to adapt the equipment to specific needs.

Another notable feature is its durability, built to withstand heavy-duty usage while maintaining optimal functionality. The equipment’s versatile nature makes it compatible with various applications, providing flexibility in its operation. These capabilities contribute to its reputation as a reliable and efficient tool.

Initial Setup and Configuration

To ensure optimal performance, the initial setup and configuration process is essential. Properly adjusting the settings and making necessary connections is the foundation for achieving smooth operation.

- Begin by positioning the equipment on a stable surface to prevent any unnecessary vibrations during use.

- Carefully connect the power source, ensuring that all cables are securely attached.

- Follow the recommended sequence for powering on the device to avoid potential issues.

Once the basic connections are established, the next step involves configuring the settings according to your specific requirements.

- Access the main control panel and navigate through the available options.

- Adjust parameters such as speed, tension, and other key settings to match the desired operational criteria.

- Save the configurations to retain the setup for future use.

Completing these steps will help you achieve a well-prepared and properly configured system, ready for efficient use.

Maintenance and Troubleshooting Tips

Ensuring the longevity and optimal performance of your equipment requires regular upkeep and careful handling. Understanding the basic principles of maintenance and knowing how to address common issues can prevent downtime and extend the lifespan of your device.

Routine Care Practices

To keep your machine in top condition, it’s essential to perform regular cleaning and inspection. Dust and debris should be removed from all accessible parts, and moving components should be lubricated periodically. Consistently check for signs of wear, such as fraying or misalignment, and address them promptly to avoid more significant problems.

Common Issues and Their Solutions

If you encounter any malfunctions, start by checking the power supply and connections. If the machine is operational but not functioning as expected, ensure that all settings are correctly adjusted and that no foreign objects are obstructing any parts. For persistent issues, consulting a professional for a thorough diagnostic may be necessary to prevent further damage.

Optimizing Performance for Best Results

Achieving optimal performance requires careful attention to various factors that can significantly impact the final outcome. By focusing on key aspects such as settings, maintenance, and usage techniques, one can ensure the highest level of efficiency and quality in their tasks.

Fine-Tuning Settings for Precision

To achieve the best results, it is crucial to fine-tune settings to match the specific requirements of the task at hand. Adjustments in parameters such as speed, tension, and alignment can make a substantial difference in the quality and consistency of the output. Regularly reviewing and calibrating these settings will help maintain precision over time.

Maintaining Equipment for Longevity

Regular maintenance plays a pivotal role in ensuring that equipment operates at its peak efficiency. Cleaning, lubricating, and inspecting the components will not only extend the lifespan of the machinery but also prevent unexpected issues. A well-maintained device delivers consistent performance, leading to superior results with minimal interruptions.

Proactive monitoring of equipment and a commitment to routine upkeep are essential for sustaining high performance and achieving the desired outcomes.

Common Issues and Solutions

When using a sewing device, users may occasionally encounter various challenges that can impact the efficiency of their work. Understanding these issues and knowing how to resolve them promptly is crucial for maintaining smooth operation and achieving high-quality results.

Thread Breakage

One frequent issue is thread breakage, which can disrupt the sewing process and cause frustration. This problem often arises due to incorrect thread tension, poor-quality thread, or improper needle size. Solution: Ensure that the tension settings are correctly adjusted for the fabric being used, and check that the needle and thread are compatible.

Skipped Stitches

Skipped stitches can lead to weak seams and an unprofessional finish. This issue may occur due to a dull needle, incorrect threading, or fabric slippage. Solution: Replace the needle regularly, ensure proper threading, and use the appropriate presser foot to stabilize the fabric during stitching.