In the realm of sophisticated electronic control systems, understanding the operational intricacies is crucial for optimal performance and maintenance. This section delves into the essential aspects of a high-performance drive unit designed to enhance and regulate mechanical functions with precision. By exploring detailed procedures and operational guidelines, users can effectively harness the full capabilities of this advanced equipment.

The purpose of this guide is to provide users with a thorough exploration of various features and configurations available in modern drive technology. Whether for installation, troubleshooting, or routine maintenance, gaining familiarity with these processes ensures efficient and reliable system operation. With clear instructions and valuable insights, users are empowered to manage and optimize their control systems proficiently.

By following the structured approach outlined herein, individuals will acquire the knowledge necessary to handle advanced drive solutions with confidence. This comprehensive resource serves as an indispensable tool for anyone seeking to master the complexities of high-tech drive systems and achieve superior performance in their applications.

Danfoss VLT 6000 Instruction Manual

This section provides essential guidance on operating and maintaining a sophisticated drive system designed for enhancing industrial performance. The focus is on offering a comprehensive overview of setup procedures, operational protocols, and troubleshooting techniques to ensure optimal functionality and longevity of the equipment. The following content aims to equip users with the necessary information to effectively manage the system and address any potential issues that may arise during its use.

Understanding the operational principles and configuration details is crucial for harnessing the full potential of this advanced drive system. Key aspects include installation instructions, operational modes, and maintenance practices. Proper adherence to these guidelines will help in achieving efficient performance and preventing common operational difficulties.

| Section | Description |

|---|---|

| Installation | Step-by-step procedures for setting up the system, including necessary preparations and initial configuration. |

| Operation | Detailed instructions on how to operate the drive system effectively, including control panel features and programming options. |

| Troubleshooting | Common issues and their solutions to ensure smooth and uninterrupted operation. |

| Maintenance | Guidelines for regular upkeep and preventive measures to prolong the lifespan of the system. |

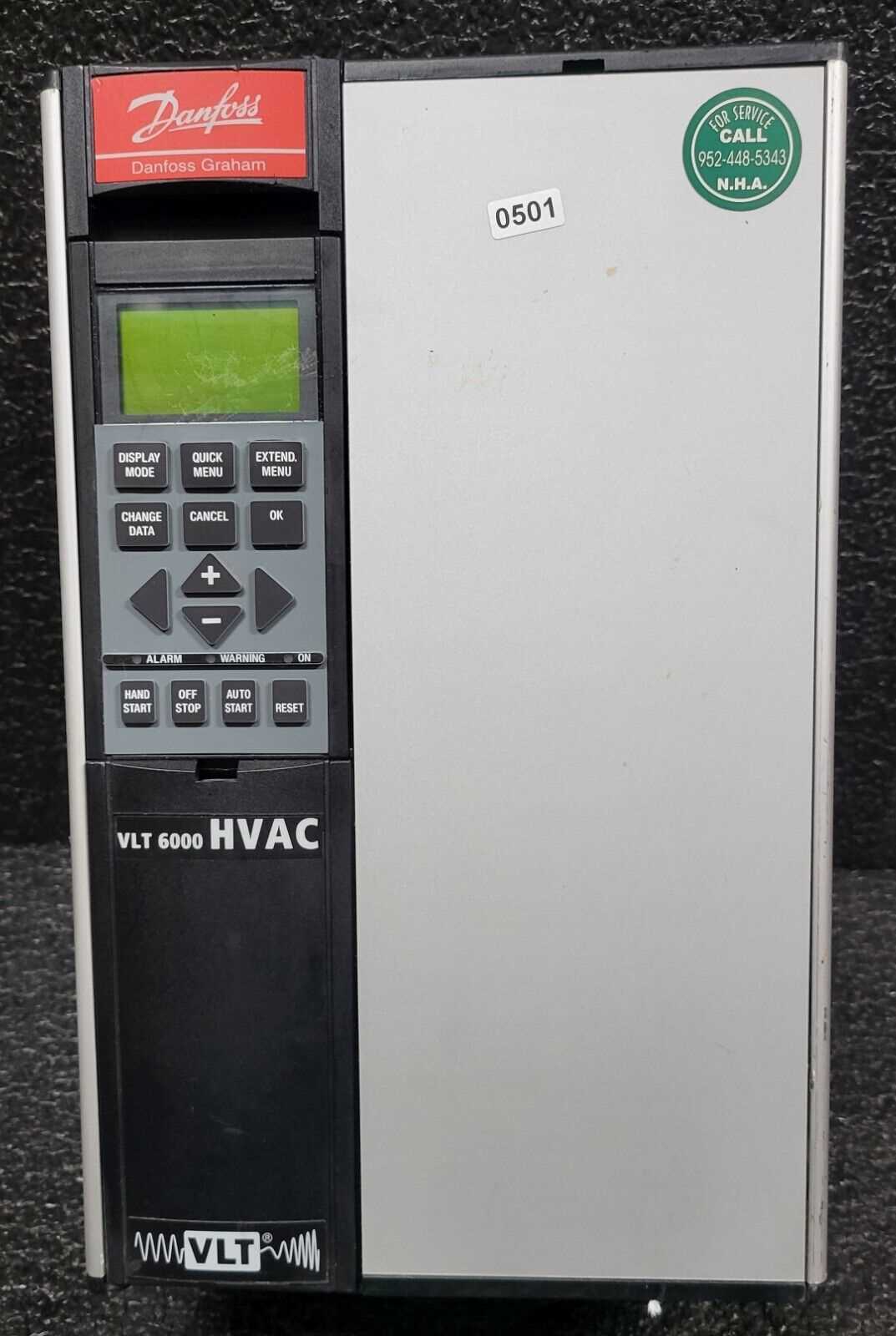

Overview of Danfoss VLT 6000

This section provides a comprehensive introduction to a versatile and efficient drive system used in a wide range of applications. Known for its adaptability and performance, this technology offers reliable solutions for optimizing energy consumption, improving process control, and enhancing system operations.

- Energy Efficiency: Designed to reduce power usage, this drive system is highly effective in cutting down energy costs, contributing to both operational savings and environmental sustainability.

- Flexible Application: It is suitable for numerous industrial and commercial environments, providing customizable settings to meet specific operational needs.

- Advanced Control: Equipped with sophisticated control mechanisms, this system ensures smooth operation, precise speed regulation, and consistent performance under varying conditions.

- Durability: Built with robust components, it offers long-lasting reliability, minimizing downtime and maintenance requirements.

- User-Friendly Interface: The interface is designed for easy programming and monitoring, enabling users to quickly adapt the system to their specific requirements.

In summary, this drive system represents a powerful tool for improving the efficiency, control, and longevity of various applications. It is a key component in achieving optimal performance and cost-effectiveness in today’s demanding environments.

Key Features and Benefits

This section outlines the primary advantages and unique functionalities that enhance the efficiency, reliability, and flexibility of the system. Designed to optimize performance, these features contribute to a seamless operational experience, ensuring long-term value.

- Enhanced Performance: The system is equipped with advanced technology that delivers superior efficiency, reducing energy consumption and operational costs.

- Comprehensive Control: A wide range of settings and adjustments allows precise control over various parameters, ensuring optimal operation under different conditions.

- Robust Reliability: Built with high-quality components, the system is engineered for durability and long-term performance, minimizing downtime and maintenance needs.

- User-Friendly Interface: An intuitive and easy-to-navigate interface simplifies setup and operation, making it accessible for users of varying expertise.

- Flexible Integration: Designed for compatibility with diverse applications, the system can be easily integrated into existing setups, offering versatility across different environments.

- Scalable Solutions: The modular design allows for easy expansion and adaptation to growing operational demands, ensuring future-proof scalability.

These features collectively enhance the system’s capability, making it a powerful tool for optimizing operational efficiency and achieving consistent results in various applications.

Installation Guidelines

Proper installation is crucial to ensuring the optimal performance and longevity of any industrial equipment. This section outlines the essential steps and considerations necessary to successfully set up your equipment, minimizing potential issues and maximizing efficiency.

Environmental Considerations

Before beginning the installation, assess the environment where the equipment will be placed. Ensure that the area is clean, dry, and free from dust or corrosive substances. The location should have adequate ventilation to prevent overheating, and the ambient temperature should remain within the specified operational range. Additionally, avoid areas prone to excessive vibration or direct sunlight, as these conditions can adversely affect the equipment’s performance.

Mounting and Positioning

Secure the equipment onto a stable and level surface. Use appropriate mounting hardware and follow the manufacturer’s specifications for spacing and clearances. This ensures that there is enough room for airflow and maintenance access. When installing multiple units, maintain the recommended distance between them to prevent interference and allow for proper cooling.

| Step | Action | Notes |

|---|---|---|

| 1 | Inspect the installation site | Ensure it meets environmental and space requirements |

| 2 | Mount the equipment | Use appropriate tools and mounting hardware |

| 3 | Check alignment and level | Ensure the unit is stable and properly aligned |

| 4 | Provide sufficient clearance | Follow recommended distances for cooling and access |

Following these guidelines will help ensure that your equipment is installed correctly, leading to reliable operation and reduced maintenance needs over time.

Operating Procedures

Understanding the correct steps for operating the drive system is crucial for ensuring efficient performance and extending the lifespan of the equipment. This section provides a detailed guide on how to start, operate, and shut down the system, ensuring optimal functionality and safety during use.

Initial Setup

Before powering on the system, ensure that all connections are secure and that the environment meets the necessary safety requirements. Check that the device is correctly configured for the intended application, including any parameters related to load capacity and speed settings.

- Verify the integrity of power connections and ensure that the grounding is correctly installed.

- Set the appropriate operational parameters according to the specific needs of the application.

- Ensure that all safety mechanisms are active and functioning properly.

Starting the System

When initiating operation, follow these steps to guarantee a smooth startup:

- Gradually apply power to the system, monitoring for any abnormal sounds or vibrations.

- Observe the control panel to ensure that all indicators show normal operation status.

- Slowly increase the load, watching for any signs of strain or instability.

- Adjust operational parameters as necessary to maintain optimal performance.

If any issues arise during startup, immediately disconnect power and troubleshoot according to the guidelines provided. Regularly monitor the system during operation to ensure consistent performance.

When shutting down, reduce the load gradually before disconnecting power, and follow the proper shutdown procedures to avoid unnecessary wear and tear on the system components.

Maintenance and Troubleshooting

Regular upkeep and prompt resolution of issues are essential for the long-term reliability and efficient operation of your equipment. This section outlines fundamental maintenance practices and provides guidance on identifying and resolving common problems.

Effective maintenance involves periodic inspections, ensuring all components are functioning within their optimal parameters, and making necessary adjustments or replacements. Below are key practices to maintain peak performance:

- Inspect electrical connections regularly for signs of wear or corrosion.

- Keep the cooling system clean and free of obstructions to prevent overheating.

- Ensure that the environment around the equipment is free of dust, moisture, and extreme temperatures.

- Monitor operating parameters, such as voltage and current, and adjust settings as needed.

- Replace worn or damaged parts promptly to avoid extended downtime.

If issues arise, troubleshooting should be approached systematically to identify the root cause. The following steps can help in diagnosing and resolving common problems:

- Check the power supply to ensure it meets the required specifications.

- Verify that all cables and connections are secure and undamaged.

- Review the operational settings to confirm they match the desired configuration.

- Examine error codes or indicators displayed on the control panel for clues about the issue.

- Consult technical documentation or seek expert advice if the problem persists after basic checks.

Adopting a proactive approach to maintenance and thorough troubleshooting will help in minimizing disruptions and extending the lifespan of your equipment.

Safety Considerations

Prioritizing safety when working with advanced electronic systems is essential to prevent accidents and equipment damage. This section outlines key safety practices to ensure secure operation and maintenance of electrical devices.

Electrical Hazards: When dealing with high-voltage systems, always be aware of the potential for electric shock. Ensure that power is completely disconnected before performing any maintenance or inspections. Utilize insulated tools and wear appropriate protective gear to minimize risk.

Proper Ventilation: Ensure that the device is installed in a well-ventilated area to prevent overheating. Overheating can lead to component failure or fire hazards. Regularly check for obstructions around the ventilation openings and remove any dust buildup.

Environmental Factors: Consider the environmental conditions where the equipment is located. Avoid exposing the unit to excessive moisture, dust, or corrosive materials, as these can degrade performance and lead to malfunction or safety hazards.

Handling and Installation: During installation or relocation, handle the equipment with care. Use appropriate lifting techniques or equipment to avoid physical injury. Ensure that all mounting fixtures are secure and that the device is properly aligned to prevent operational issues.

Routine Inspections: Conduct regular inspections and maintenance checks to identify potential safety concerns early. Look for signs of wear, damage, or loose connections, and address them promptly to maintain a safe operational environment.

Emergency Procedures: Familiarize yourself with emergency shutdown procedures in case of equipment failure or unexpected events. Ensure that all personnel are trained to respond appropriately to emergency situations to minimize harm and damage.