When working with complex drive systems, having a clear understanding of their operation is crucial for both efficiency and safety. This guide aims to provide a comprehensive overview of how to navigate and utilize these systems effectively. Whether you are setting up a new unit or troubleshooting an existing one, the following sections will offer valuable insights into essential functionalities and settings.

Our objective is to simplify the management of your drive unit by detailing key aspects of its operation. This includes configuring settings, monitoring performance, and addressing common issues. With step-by-step instructions and practical advice, you will be well-equipped to handle your equipment with confidence.

By familiarizing yourself with these guidelines, you will enhance your ability to operate and maintain your drive system smoothly. This approach ensures that you maximize performance and longevity while minimizing potential disruptions.

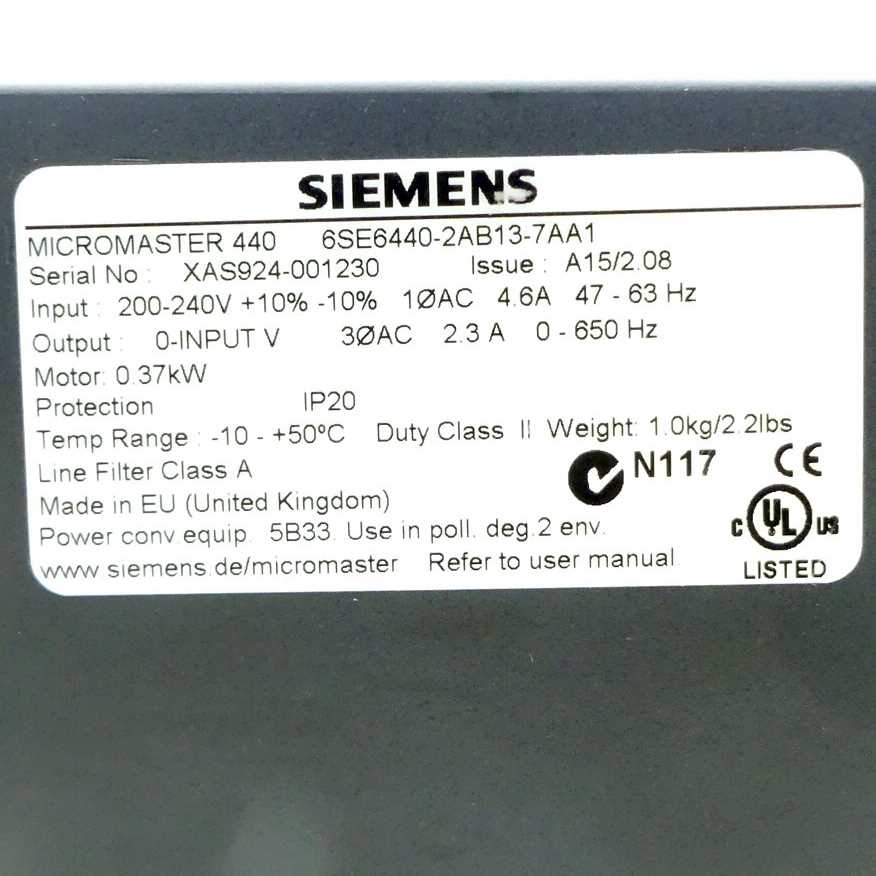

Siemens Micromaster 440 Operating Instructions Manual

This section provides essential guidelines for the effective use and management of the drive system. It covers crucial aspects of setup, configuration, and daily operation to ensure optimal performance. Detailed explanations are provided to assist users in understanding how to operate and maintain the equipment efficiently. Following these guidelines will help in achieving the best results and prolonging the lifespan of the device.

Understanding the Siemens Micromaster 440

In the realm of industrial automation, certain devices play a crucial role in controlling and optimizing various mechanical processes. These devices are integral to ensuring efficient operation and precise control over machinery. Their functionality and configuration can significantly impact performance and operational efficiency.

Among these devices, some offer advanced features and flexibility, allowing for extensive customization to meet specific operational needs. Understanding the underlying principles and capabilities of these units can provide valuable insights into their optimal use and maintenance.

Key Features and Specifications

This section provides an overview of the fundamental attributes and technical details of the device. Understanding these key aspects is essential for leveraging the full potential of the equipment in various applications.

Performance Characteristics

The device is designed to offer robust performance across a range of settings. It supports precise control over speed and torque, enabling efficient operation and adaptation to different load conditions. Key performance metrics include:

- Speed Range: Adjustable within a broad spectrum to match various operational requirements.

- Torque Capacity: Capable of handling substantial torque loads for diverse tasks.

- Efficiency: Engineered to optimize energy consumption and reduce operational costs.

Technical Specifications

Detailed technical specifications ensure that the equipment meets the necessary standards for reliability and durability. Key specifications include:

- Voltage Range: Designed to operate within specific voltage parameters to ensure safety and functionality.

- Current Rating: Accommodates varying current levels for different applications.

- Communication Protocols: Supports multiple communication protocols for seamless integration with other systems.

Setup and Installation Guidelines

Ensuring proper setup and installation of your equipment is crucial for its optimal performance and longevity. This section provides essential steps and considerations for correctly installing and configuring your system to achieve the best results. Follow these guidelines to avoid common issues and ensure smooth operation from the start.

Initial Preparations: Before beginning the installation process, carefully review the provided documentation and verify that all necessary components and tools are available. Proper preparation helps streamline the setup process and prevents delays.

Location and Mounting: Choose an appropriate location for installation that meets the environmental and operational requirements specified. Ensure the area is clean, well-ventilated, and free from obstructions. Securely mount the unit according to the manufacturer’s recommendations to avoid any operational issues.

Electrical Connections: Connect the equipment to the power supply following the electrical specifications outlined in the documentation. Proper wiring and connection are essential for the safe and efficient functioning of the system. Double-check all connections to ensure they are secure and correctly configured.

Configuration and Testing: Once the equipment is installed and connected, proceed with the initial configuration settings. Follow the setup instructions to adjust parameters and calibrate the system as needed. Conduct thorough testing to confirm that the equipment operates correctly and meets performance expectations.

By adhering to these setup and installation guidelines, you can ensure a successful implementation of your system, enhancing its reliability and efficiency in the long run.

Operating Modes and Configurations

Understanding the various operational modes and configurations is essential for optimizing the performance of your device. This section covers the fundamental concepts and options available to tailor the device’s functionality to meet specific requirements. By exploring these settings, you can ensure the equipment operates efficiently and effectively within its intended applications.

Operational Modes

Devices typically offer a range of operational modes to accommodate different tasks and environments. Each mode is designed to handle specific types of operations, providing flexibility and adaptability. Standard mode is commonly used for routine applications, while advanced mode allows for more complex tasks and fine-tuning of parameters.

Configuration Options

Configuration settings enable users to customize the device’s performance and functionality. Options may include adjusting speed control, torque settings, and feedback mechanisms. Proper configuration ensures that the equipment operates within desired specifications and meets the demands of its operational context.

Troubleshooting Common Issues

When dealing with equipment, encountering problems is a common experience. This section provides guidance on identifying and resolving frequent issues that users may face. By systematically addressing these problems, you can ensure that the system operates efficiently and reliably.

Below is a table outlining typical issues, possible causes, and suggested solutions:

| Issue | Possible Causes | Suggested Solutions |

|---|---|---|

| Equipment fails to start | Power supply issues, faulty wiring, or control settings | Check the power connection and wiring. Verify control settings and ensure the equipment is properly configured. |

| Overheating | Inadequate ventilation, blocked cooling fans, or excessive load | Ensure proper ventilation around the equipment. Clean cooling fans and check the load to make sure it is within the recommended limits. |

| Erratic performance | Interference, calibration issues, or defective components | Check for any sources of interference. Recalibrate the system if necessary and inspect components for defects or damage. |

| Unusual noises | Loose parts, worn bearings, or mechanical faults | Inspect for any loose parts and tighten them. Replace worn bearings and address any mechanical faults as required. |

Maintenance and Safety Precautions

Proper upkeep and adherence to safety guidelines are crucial for ensuring the optimal performance and longevity of your equipment. Regular maintenance not only helps in preventing unexpected breakdowns but also enhances the overall efficiency and reliability of the system. Additionally, observing safety precautions minimizes the risk of accidents and protects both personnel and machinery from potential hazards.

Follow these maintenance and safety practices to ensure smooth operation:

| Maintenance Task | Frequency | Details |

|---|---|---|

| Inspection | Monthly | Check for any signs of wear or damage. Ensure all components are functioning correctly. |

| Cleaning | Quarterly | Remove dust and debris from the unit to prevent overheating and ensure proper ventilation. |

| Lubrication | Bi-annually | Apply lubricant to moving parts to reduce friction and prevent premature wear. |

| Calibration | Annually | Adjust settings and calibrate equipment to maintain accuracy and performance standards. |

Always ensure that the equipment is turned off and disconnected from the power source before performing any maintenance tasks. Use appropriate personal protective equipment (PPE) and follow all manufacturer guidelines to ensure safety and proper handling. Regular maintenance and strict adherence to safety protocols will help in maintaining the efficiency and extending the service life of your equipment.