Managing a system designed to ensure the purity and safety of public resources requires a deep understanding of complex processes. This section delves into the essential practices and knowledge required to oversee and maintain the operations of these vital systems. Through comprehensive insights, the content aims to equip those responsible with the necessary tools to perform their duties effectively.

Key areas of focus include the principles of system maintenance, the importance of routine monitoring, and the steps necessary to respond to common challenges. By understanding the intricacies of these operations, caretakers can better preserve the integrity of the system and ensure it continues to meet safety standards.

Additionally, this guide highlights critical procedures that must be followed to maintain optimal functioning. Emphasis is placed on proactive measures and troubleshooting techniques, empowering those in charge to handle issues swiftly and competently.

Manual of Instruction for Water Treatment Plant Operators

The section provides an overview of key practices and guidelines essential to ensuring the effective management and operation of facilities dedicated to the purification and distribution of drinking resources. The content focuses on critical procedures, operational standards, and safety protocols to maintain optimal performance and compliance with regulatory requirements.

Core Responsibilities

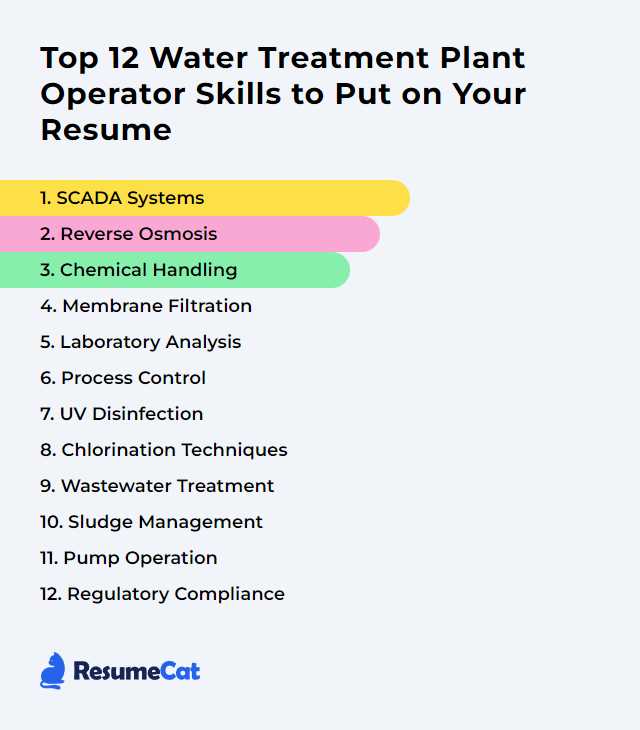

Professionals in this field are tasked with a range of duties that ensure the quality and safety of the end product. Below are some of the primary responsibilities:

- Monitoring and adjusting various processes to achieve desired purity levels.

- Performing routine inspections to identify potential issues or malfunctions.

- Maintaining accurate records of operational data and incidents.

- Ensuring compliance with environmental and health regulations.

- Conducting regular maintenance and repair tasks to prevent disruptions.

Key Operational Guidelines

Adhering to specific guidelines is crucial in maintaining the efficiency and reliability of the system. These include:

- Regularly calibrating instruments and sensors to ensure accurate measurements.

- Implementing preventive measures to reduce the likelihood of contamination.

- Training personnel to handle emergencies and unexpected scenarios.

- Establishing a systematic approach to chemical handling and storage.

- Continuously reviewing and updating procedures based on technological advancements.

By following these practices, professionals can ensure the consistent delivery of a safe and high-quality product, safeguarding public health and meeting industry standards.

Understanding Water Purification Processes

Effective purification is essential to ensure that the liquid resource we rely on is safe and clean. This section delves into the various methods utilized to remove impurities and harmful substances, transforming raw sources into a resource suitable for consumption and use. These processes are critical in maintaining public health and ensuring that communities have access to a vital, uncontaminated resource.

The purification journey typically involves multiple stages, each designed to address specific contaminants. These stages can be broadly categorized as follows:

- Coagulation and Flocculation: Initial steps where particles are aggregated into larger clusters, facilitating easier removal.

- Filtration: The separation of suspended particles from the liquid through various media, ensuring clarity.

- Disinfection: The application of chemical or physical agents to eliminate pathogenic organisms, safeguarding public health.

- pH Adjustment: Balancing the acidity or alkalinity to stabilize the treated liquid and prevent corrosion in distribution systems.

Each stage in the process is meticulously designed and executed to handle different types of impurities, from suspended solids to microorganisms, ensuring that the final product meets safety standards. Understanding these processes is key to ensuring the resource’s quality and safety.

Essential Equipment in Water Treatment Plants

The effectiveness and reliability of purification facilities depend heavily on a range of specialized machinery and tools. Each component plays a crucial role in ensuring that the process operates smoothly, maintaining both efficiency and safety. By understanding the core pieces of machinery, one can appreciate how they contribute to the overall functionality of these facilities.

Pumps are integral to the movement of fluids throughout the system, facilitating the transportation of liquids between various stages of processing. These devices must be selected based on their capacity to handle different volumes and types of liquids, ensuring consistent flow and pressure.

Mixing Tanks provide the environment needed for combining different substances. These containers allow for the thorough integration of additives, helping to achieve desired chemical reactions or preparing mixtures for further refinement.

Filtration Units serve the critical function of removing unwanted particles from liquids. These systems can vary in complexity, from basic screens to advanced multi-stage filters, and are essential in achieving the desired level of clarity and purity.

Chemical Dosing Systems ensure precise introduction of additives into the system. Accurate dosage is crucial to achieving the intended chemical balance, impacting the effectiveness of subsequent processes.

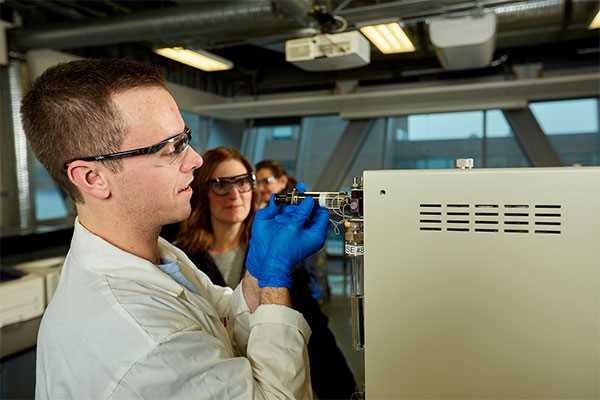

Measurement and Monitoring Instruments provide real-time data on various parameters such as pH levels, flow rates, and turbidity. These devices are key to maintaining control over the process, enabling timely adjustments and ensuring compliance with quality standards.

Disinfection Units are used to eliminate harmful microorganisms. These systems can utilize different methods, such as ultraviolet light or chemical disinfectants, to ensure that the final product meets safety requirements.

Sludge Management Systems handle the byproducts of the process, collecting and processing solid residues. Efficient handling of these materials is essential to maintaining the cleanliness and efficiency of the facility.

Each piece of equipment is vital, working together to achieve the high standards required in the purification process. Understanding their roles helps ensure that the system operates at its best, providing consistent and reliable results.

Monitoring and Maintaining Water Quality Standards

Ensuring the highest standards of liquid purity is crucial for safeguarding public health and the environment. Regular assessment of liquid characteristics helps in identifying potential issues early and allows for timely corrective actions. This section focuses on the essential practices and techniques required to consistently achieve optimal purity levels.

Key Parameters to Track

Continuous observation of various chemical, physical, and biological markers is vital. These include indicators such as pH levels, turbidity, and the presence of microbial contaminants. Each parameter offers insights into different aspects of purity, making it essential to track them closely to maintain the desired quality.

Proactive Measures and Regular Adjustments

To uphold the necessary standards, it is important to implement proactive strategies. Regular calibration of monitoring equipment, routine sample collection, and frequent analysis are fundamental. Additionally, making immediate adjustments based on data trends ensures that any deviations are corrected swiftly, preventing long-term issues.

Consistency in maintaining these practices ensures that purity levels remain within the desired range, contributing to the overall safety and reliability of the system.

Safety Protocols for Water Treatment Facilities

Ensuring a secure working environment within facilities dedicated to managing and processing essential resources is paramount. Implementing comprehensive safety measures helps mitigate risks and safeguard personnel, equipment, and the surrounding environment. Proper guidelines and practices play a critical role in maintaining operational integrity and minimizing hazards.

General Safety Guidelines

Adhering to established safety protocols is crucial in preventing accidents and ensuring smooth operations. Regular training sessions should be conducted to keep the staff well-informed about emergency procedures and the use of personal protective equipment. Routine inspections and maintenance of machinery help to identify potential issues before they become serious problems. Additionally, clear communication channels must be maintained to quickly address any safety concerns or incidents that may arise.

Emergency Response Procedures

In the event of an emergency, having a well-defined response plan is essential. This includes identifying potential emergency scenarios such as chemical spills, equipment malfunctions, or natural disasters. Each scenario should have a corresponding action plan that details steps to be taken, including evacuation procedures and emergency contacts. Regular drills and exercises help ensure that all personnel are familiar with their roles and responsibilities during an emergency, enhancing overall preparedness and response effectiveness.

Optimizing Efficiency in Water Treatment Operations

Maximizing operational performance involves enhancing various facets of the process to achieve the best possible outcomes with minimal waste. By focusing on key areas, such as resource management, technology integration, and procedural adjustments, facilities can ensure that every step contributes effectively to overall goals.

One of the primary strategies is to employ advanced technologies that streamline tasks and improve accuracy. Automated systems can reduce human error and increase reliability, while real-time monitoring allows for quick adjustments and better control over the entire process.

Another crucial aspect is the training and development of personnel. Well-informed staff can operate systems more efficiently and respond to issues proactively, thus minimizing downtime and maintaining high standards of performance.

Regular maintenance and timely upgrades of equipment are essential to prevent inefficiencies and prolong the lifespan of machinery. Implementing a preventive maintenance schedule helps in identifying potential problems before they escalate, ensuring smoother operations.

| Strategy | Description | Benefits |

|---|---|---|

| Technology Integration | Utilizing advanced systems and automation | Increased accuracy and reduced human error |

| Personnel Training | Comprehensive training programs for staff | Enhanced operational efficiency and quick issue resolution |

| Preventive Maintenance | Regular upkeep and timely upgrades of equipment | Minimized downtime and extended equipment lifespan |

By implementing these strategies, facilities can achieve significant improvements in efficiency, leading to better outcomes and more sustainable operations.

Troubleshooting Common Water Treatment Issues

Identifying and resolving frequent challenges in purification processes is essential to maintaining efficient operations. This section focuses on the most typical difficulties that can arise, offering approaches to quickly pinpoint the root cause and find the optimal solution.

-

Discoloration in Output: If unusual colors appear in the output, examine filtration systems and chemical balances. Pay attention to changes in flow rate and pressure that might indicate blockages or incorrect dosages.

-

Unpleasant Odor or Taste: Sudden changes in odor or flavor may suggest issues with oxidation or disinfection. Review chemical processes and aeration stages to ensure proper function.

-

Pressure Drops: Gradual or sudden drops in pressure can signal obstructions in pipes or malfunctioning pumps. Regular maintenance checks and filter cleaning can prevent these disruptions.