In the realm of automated systems, effective management of control units is crucial for optimal performance and reliability. This guide is designed to provide you with the essential knowledge and techniques necessary for operating your device with confidence and precision. It covers various facets of the controller, ensuring you have a clear understanding of its functionality and configuration.

Throughout this document, you will explore key aspects of the device, including setup procedures, operational guidelines, and troubleshooting tips. With a focus on practical application, this resource aims to enhance your expertise and facilitate seamless integration of the controller into your system. Mastering these elements will enable you to harness the full potential of your equipment and achieve the best possible outcomes.

Whether you are new to this type of technology or looking to refine your skills, this guide will serve as a valuable reference. Delve into each section to uncover detailed instructions and insights that will assist you in managing and optimizing your control unit effectively.

Overview of Omron E5CB Controller

The temperature and process controllers are essential components in industrial automation, designed to enhance precision and reliability in various applications. This section provides a detailed examination of one such device, highlighting its core features and functionalities.

- Functionality: This controller excels in managing temperature and process variables, ensuring optimal performance and efficiency.

- Display: It features an intuitive display that facilitates easy monitoring and adjustments, even in complex setups.

- Control Modes: The device supports multiple control modes, including PID, ON/OFF, and more, adapting to different operational requirements.

- Ease of Use: With user-friendly programming options and a straightforward interface, it simplifies configuration and operation.

- Versatility: Suitable for a variety of applications, it integrates seamlessly with different systems and processes.

In summary, this controller provides the ultimate in flexibility and precision, making it a valuable tool for enhancing industrial processes.

Key Features and Specifications

This section provides an overview of the most important characteristics and technical details of the device. Understanding these elements is essential for selecting the right unit for your needs and ensuring it meets the performance criteria required for your specific applications.

Key Features:

- Display: The unit features a clear and intuitive display for easy reading and programming.

- Inputs: It supports multiple input types, allowing flexibility in various setups.

- Outputs: Equipped with reliable output options for controlling different processes.

- Programming: Offers user-friendly programming interfaces for quick configuration.

Specifications:

- Temperature Range: Operates within a wide temperature range for diverse environments.

- Power Supply: Requires standard power input for straightforward integration.

- Accuracy: Provides high precision in measurements and control.

- Durability: Designed to be robust and reliable in industrial settings.

How to Set Up the E5CB

Configuring your temperature controller involves several essential steps to ensure accurate operation and optimal performance. The process typically includes connecting the device, setting parameters, and calibrating it to match your specific needs. Here’s a comprehensive guide to help you through the setup process effectively.

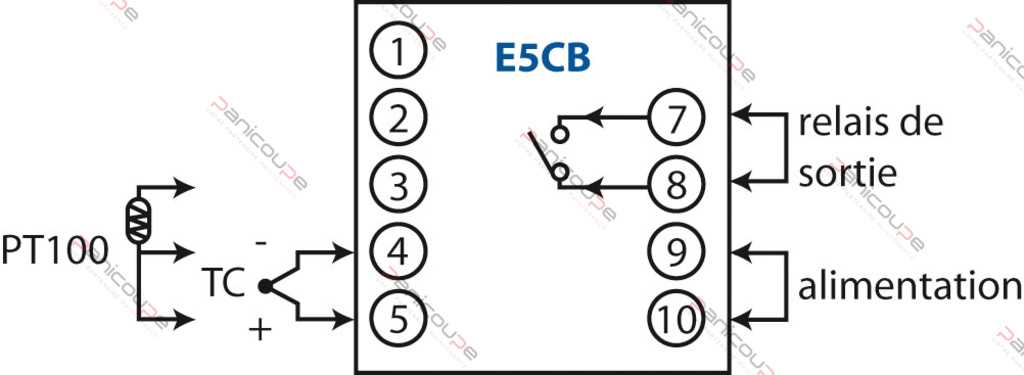

- Connecting the Device: Begin by wiring the controller to your power supply and sensors. Ensure all connections are secure and follow the wiring diagram provided with your equipment. Pay special attention to polarity and correct terminal connections to avoid any electrical issues.

- Power On: Once connected, power up the unit. You should see the display activate, indicating that the device is receiving power. If the display does not turn on, check your connections and power source.

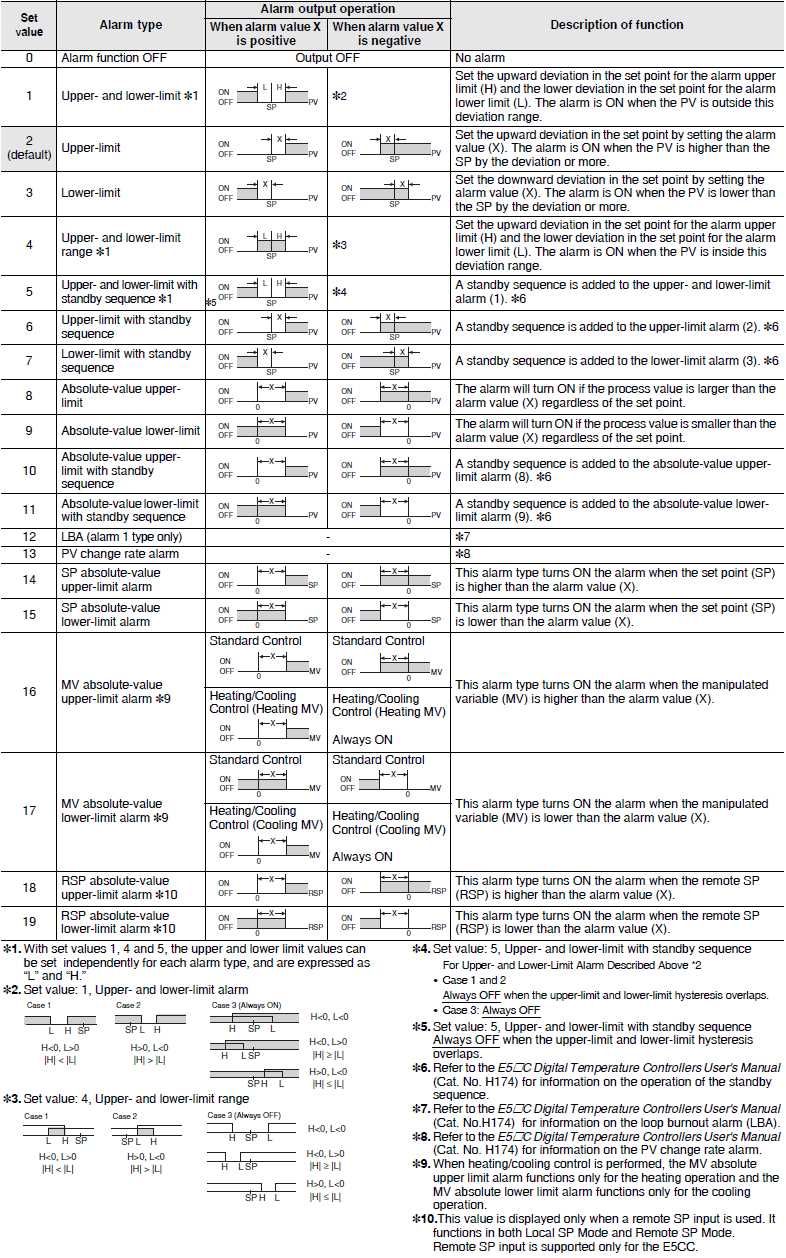

- Configure Parameters: Access the configuration menu by navigating through the display settings. Set the desired parameters such as temperature range, control mode, and output settings. Refer to the guidelines specific to your application to input accurate values.

- Calibration: To ensure precise temperature readings, calibrate the controller according to the manufacturer’s recommendations. This step may involve adjusting settings based on a known reference temperature or using calibration equipment.

- Testing: After setup and calibration, conduct a test run to verify that the controller operates as expected. Monitor the output and temperature readings to ensure they align with your settings and make any necessary adjustments.

- Final Checks: Perform a final review of all connections and settings. Confirm that the device is functioning correctly and that all parameters are set as required for your application.

Following these steps will help you successfully set up your temperature controller, ensuring reliable and accurate performance for your system.

Understanding the User Interface

Getting acquainted with the interface of a device is crucial for effective usage. This section will guide you through the essential elements and functions, ensuring you can navigate and operate the system with confidence. By exploring these features, you’ll be better equipped to make the most of the device’s capabilities.

Key Components

- Display Screen: Provides visual feedback and access to settings.

- Buttons and Controls: Allow user interaction and configuration adjustments.

- Indicators: Show status and alert users to important conditions.

Navigation Tips

- Familiarize yourself with the menu structure for efficient access to functions.

- Use the buttons systematically to avoid accidental changes.

- Refer to the indicators for real-time updates on the system’s status.

Troubleshooting Common Issues

When working with complex electronic devices, encountering issues is a common experience. This section aims to guide you through resolving frequent problems that may arise. By addressing these common issues systematically, you can restore optimal performance and ensure the reliable operation of your equipment.

If you notice that the device is not powering on, first check the power connections and ensure that the device is properly plugged in. Verify that the power source is functioning by testing it with another device or using a multimeter to check for voltage. Additionally, examine the fuse or circuit breaker to rule out any electrical issues.

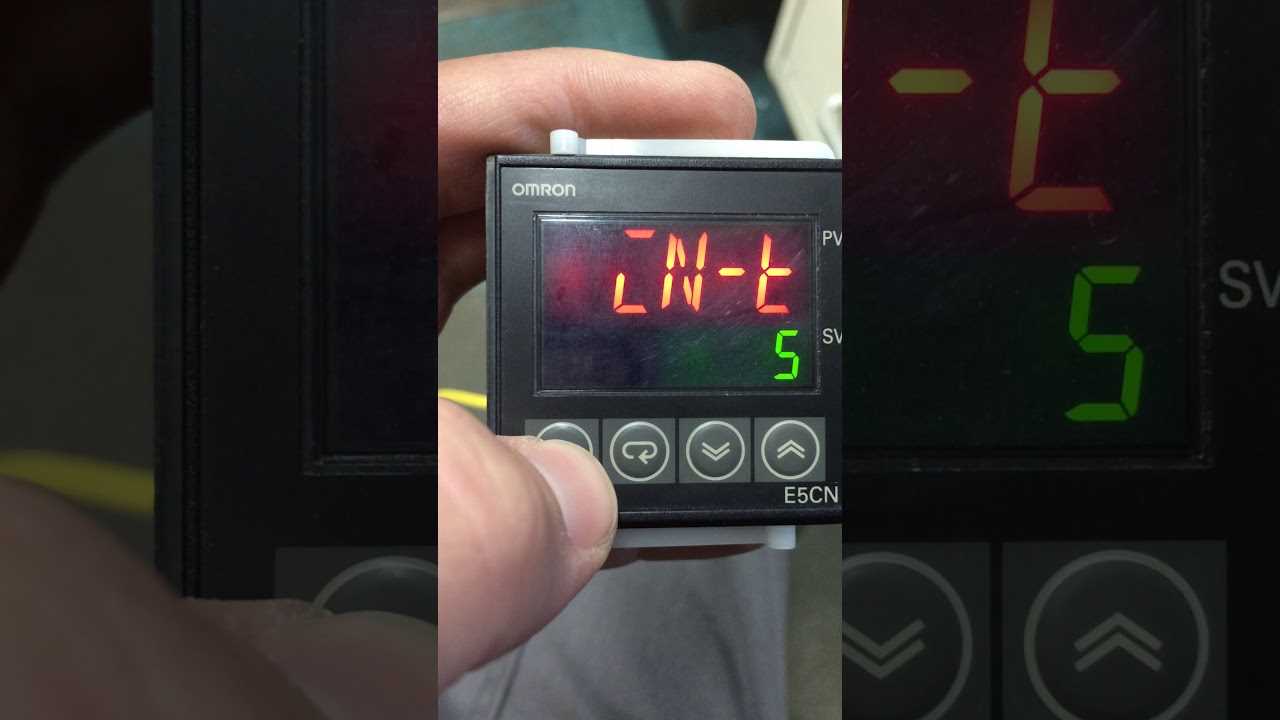

In cases where the display is not functioning correctly or is showing erroneous information, try resetting the device to its factory settings. This can often resolve display-related glitches. Make sure that the connections to the display are secure and free from any physical damage. If the issue persists, consider checking for firmware updates or contacting support for further assistance.

For problems related to inaccurate readings or measurements, calibrate the device according to the manufacturer’s instructions. Ensure that all sensors and input connections are properly attached and not obstructed. Regular maintenance and calibration can help maintain accurate performance and prevent measurement discrepancies.

If the device emits unusual noises or vibrations, inspect it for any loose components or mechanical issues. Sometimes, such noises can indicate internal problems that require professional servicing. Regular inspection and maintenance can prevent such issues from escalating.

By following these troubleshooting steps, you can effectively address and resolve common issues, ensuring the continued functionality and reliability of your equipment. For persistent problems beyond these solutions, consult with a technical expert or support service for advanced troubleshooting and repair options.

Maintenance and Care Tips

Proper upkeep is crucial for ensuring the longevity and optimal performance of your device. Regular maintenance not only prevents unexpected issues but also extends the lifespan of the equipment. By adhering to routine care practices, you can enhance the reliability and accuracy of your system.

1. Regular Cleaning: Keep the device clean and free from dust and debris. Use a soft, dry cloth to wipe the exterior. Avoid using abrasive materials or harsh chemicals that could damage the surface.

2. Check Connections: Periodically inspect all electrical connections and cables for signs of wear or damage. Ensure that all connectors are securely attached and free from corrosion.

3. Calibration: Perform regular calibration checks to maintain accurate readings. Follow the manufacturer’s guidelines for calibration procedures and intervals.

4. Environment: Place the device in a stable environment with controlled temperature and humidity. Avoid exposure to extreme conditions that could affect performance.

5. Professional Servicing: For any internal issues or complex maintenance tasks, seek professional assistance. Attempting repairs yourself could void warranties or cause further damage.

Safety Precautions and Best Practices

Ensuring safety and efficiency when using electronic devices is crucial. Adhering to best practices can prevent accidents and ensure optimal performance. Here are key guidelines to follow:

- Always read the product documentation thoroughly before installation or operation.

- Ensure that the device is installed by a qualified technician to avoid potential hazards.

- Verify that all connections are secure and meet the required specifications.

Maintaining proper operational procedures is equally important:

- Regularly inspect the device for any signs of damage or wear.

- Follow recommended maintenance schedules to ensure reliable performance.

- Implement safety measures such as circuit breakers or emergency stop functions where applicable.

By following these precautions, you can ensure both safety and the ultimate functionality of your equipment.