In this guide, you will discover how to effectively operate your labeling equipment. This resource is designed to assist you in mastering the use of your device, ensuring you can perform tasks with ease and accuracy.

First, you’ll gain insight into the basic functionalities and features of the machine. The objective is to familiarize yourself with the essential components and their roles in the labeling process.

Next, the guide will provide detailed instructions on setting up and utilizing the equipment for various applications. This will help you optimize its performance and achieve the best results for your labeling needs.

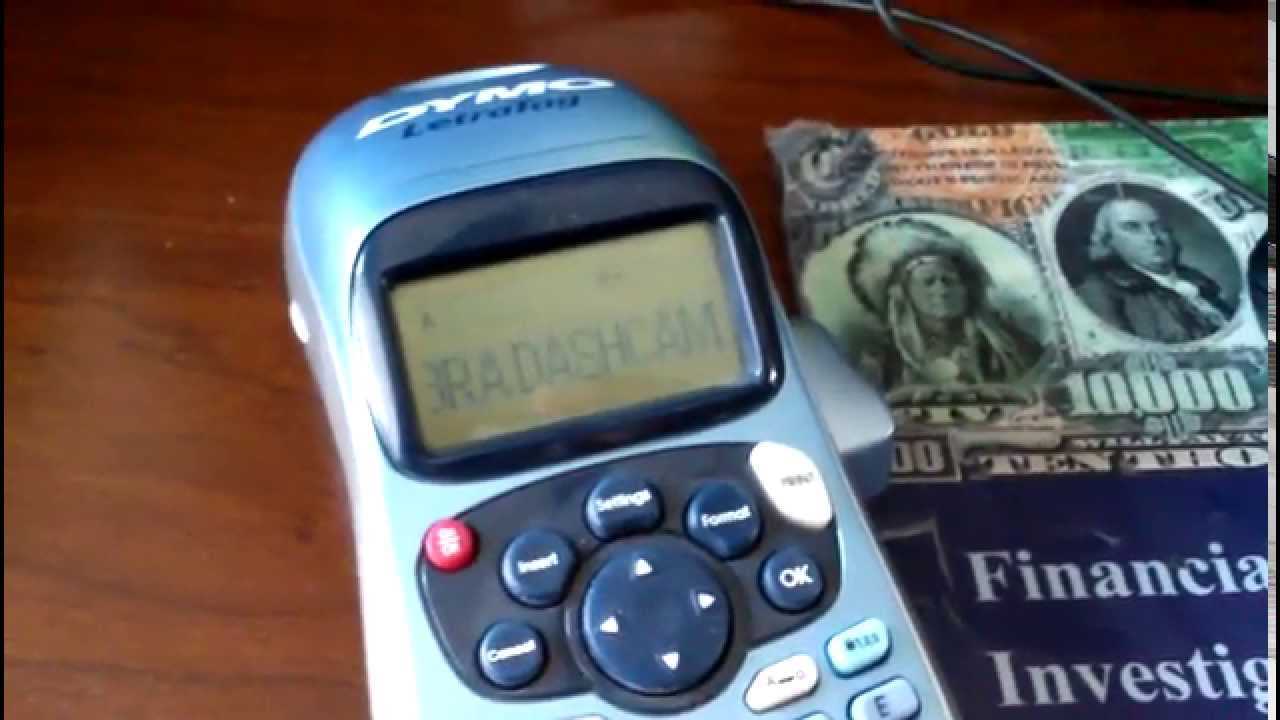

Overview of Labeling Device Features

This section provides a comprehensive look at the essential characteristics and functionalities of the labeling device in question. By exploring its primary attributes, users can better understand how this tool supports effective labeling and organization in various settings.

| Feature | Description |

|---|---|

| Design | Compact and ergonomic design for easy handling and usage. |

| Label Types | Supports various label sizes and materials for versatile applications. |

| Print Technology | Utilizes advanced printing technology for clear and precise labels. |

| User Interface | Features an intuitive interface for effortless navigation and operation. |

| Connectivity | Offers options for connecting to other devices for streamlined data management. |

Getting Started with Your Device

Begin by familiarizing yourself with the essential functions and features of your new gadget. Understanding the basic operations will ensure you can make the most out of its capabilities right from the start.

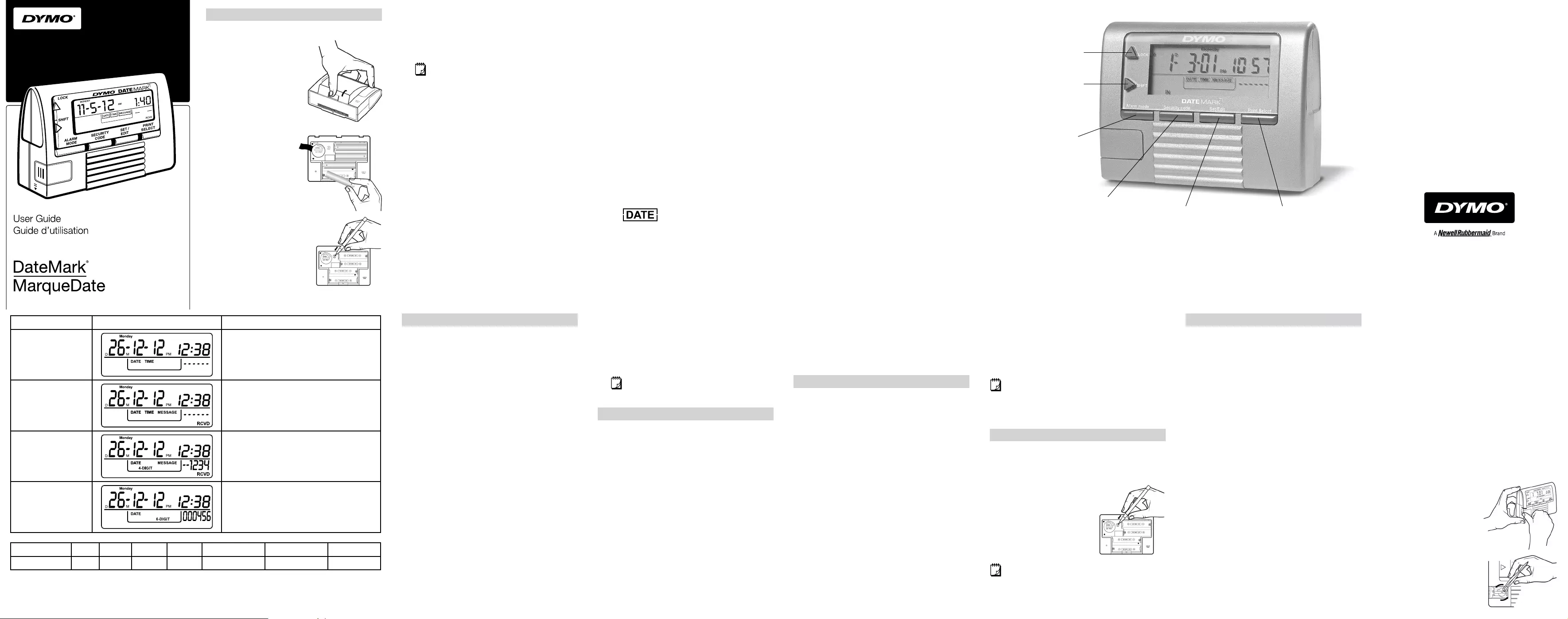

Unboxing and Initial Setup

Carefully unpack the device and ensure all components are included. Connect the device to a power source or insert the necessary batteries. Follow the initial setup instructions to power up and configure basic settings.

Basic Operation and Navigation

Once your device is set up, learn how to navigate its primary functions. Explore the user interface and familiarize yourself with the key buttons and display features. This will help you efficiently use the device for your needs.

Understanding Label Types and Sizes

Labels come in a variety of types and dimensions, each suited to different purposes and applications. Grasping the different options available helps in selecting the most appropriate label for your specific needs, whether for organizing, identifying, or creating visual presentations.

- Types of Labels:

- Address Labels: Ideal for mailing and shipping, these labels are generally larger and designed to clearly display addresses.

- File Folder Labels: Used for categorizing and organizing files, these labels are typically smaller and can fit neatly on file folders.

- Barcode Labels: These labels are used for tracking and inventory purposes, often including barcode data for scanning.

- Industrial Labels: Built to withstand harsh conditions, these labels are made from durable materials and can resist water, chemicals, and extreme temperatures.

- Label Sizes:

- Small Labels: Suitable for small items or compact spaces. Commonly used for labeling files, folders, or small products.

- Medium Labels: Versatile size for a wide range of applications, including product labeling and general organization.

- Large Labels: Designed to stand out and be easily readable. Often used for shipping packages or labeling large items.

- Custom Sizes: Labels can also be produced in custom dimensions to meet specific needs, ensuring a perfect fit for any application.

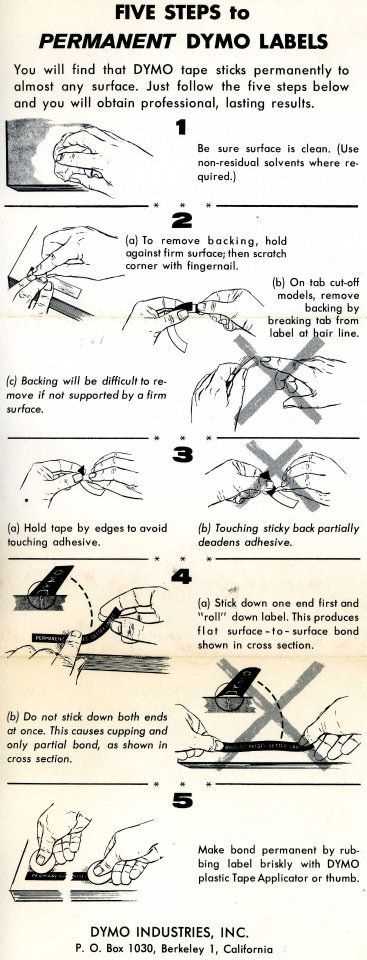

Step-by-Step Installation Guide

Setting up your labeling device is a straightforward process when following these clear instructions. Begin by carefully reviewing each step to ensure a smooth installation experience. This guide will walk you through the essential procedures, from initial setup to final configuration, helping you get your device up and running efficiently.

Start by unboxing all components and verifying that nothing is missing. Make sure you have all necessary parts before proceeding. Then, assemble the device according to the provided schematic. This usually involves connecting key components and securing them properly. Next, install the required software on your computer if applicable, ensuring compatibility with your operating system.

Finally, perform a test run to confirm that everything functions as expected. Follow any on-screen prompts or additional instructions to finalize the setup. Once completed, your labeling system should be ready for use, allowing you to start with your labeling tasks effectively.

Customizing Your Label Settings

Adjusting the label settings allows you to tailor the output to your specific needs. This process involves configuring various parameters to ensure that the labels meet your exact specifications. By modifying these settings, you can enhance the clarity and functionality of the printed labels.

Adjusting Print Options

Begin by selecting the print options that best suit your requirements. These options include adjusting the label size, font type, and print quality. You can experiment with different settings to achieve the desired outcome.

| Setting | Description |

|---|---|

| Label Size | Choose the dimensions of your labels to fit the intended surface area. |

| Font Style | Select the font that enhances readability and fits the label’s purpose. |

| Print Quality | Adjust the resolution to ensure clear and sharp text and images. |

Saving and Applying Settings

Once you have customized the settings, save your preferences to apply them to your current and future labels. This step ensures that your customized settings are preserved, streamlining the labeling process.

Common Troubleshooting Tips

When encountering issues with label printing devices, it’s essential to follow some general guidelines to address common problems effectively. Here are a few tips to help you resolve typical challenges and ensure smooth operation of your equipment.

- Check Power Supply: Ensure that the device is properly connected to a power source and that the power cable is securely attached.

- Verify Label Alignment: Confirm that the labels are correctly positioned in the printer and that they are feeding through the mechanism without obstruction.

- Inspect for Jams: Look for any paper jams or debris within the device that may be causing operational issues. Remove any obstructions carefully.

- Update Software: Make sure that the printer’s software or firmware is up to date, as outdated versions can lead to functionality problems.

- Reset the Device: Try restarting the printer to reset its internal settings and resolve minor glitches.

- Check Connectivity: Ensure that all cables and connections are properly secured if the device is connected to a computer or network.

Following these troubleshooting steps can help you resolve most common issues and maintain the efficient performance of your label printer.

Maintaining and Cleaning Your Labeler

Proper upkeep and sanitation of your labeling device are essential for ensuring its long-term performance and accuracy. Regular maintenance helps to prevent malfunctions and prolongs the life of your equipment.

- Regular Cleaning: Wipe the exterior and interior parts of the labeler with a soft, dry cloth to remove dust and residue. Avoid using harsh chemicals that could damage the device.

- Ink and Tape Check: Regularly inspect and replace the ink cartridges and tape rolls as needed to maintain optimal printing quality. Ensure that these components are correctly installed and free from obstructions.

- Internal Inspection: Periodically open the labeler to check for any buildup of adhesive or other debris inside. Carefully remove any accumulated materials to prevent jams or mechanical issues.

By following these maintenance and cleaning tips, you can ensure that your labeling device remains in good working condition and continues to function efficiently.