For those embarking on the journey of mastering a high-performance fabric manipulation tool, understanding its intricacies is essential. This section is dedicated to providing you with detailed insights into the operation and maintenance of your advanced stitching apparatus. By delving into this guide, you’ll acquire the knowledge needed to optimize its functionality and ensure its longevity.

From basic setup to advanced techniques, the following information will serve as a roadmap to navigating and harnessing the full potential of your equipment. Each step and feature will be explained in a clear and concise manner, ensuring that you can confidently manage and utilize your tool with precision.

Whether you are new to this type of equipment or looking to refine your skills, this resource will offer valuable guidance to enhance your experience. By following these instructions, you will be well-equipped to achieve excellent results in your fabric projects.

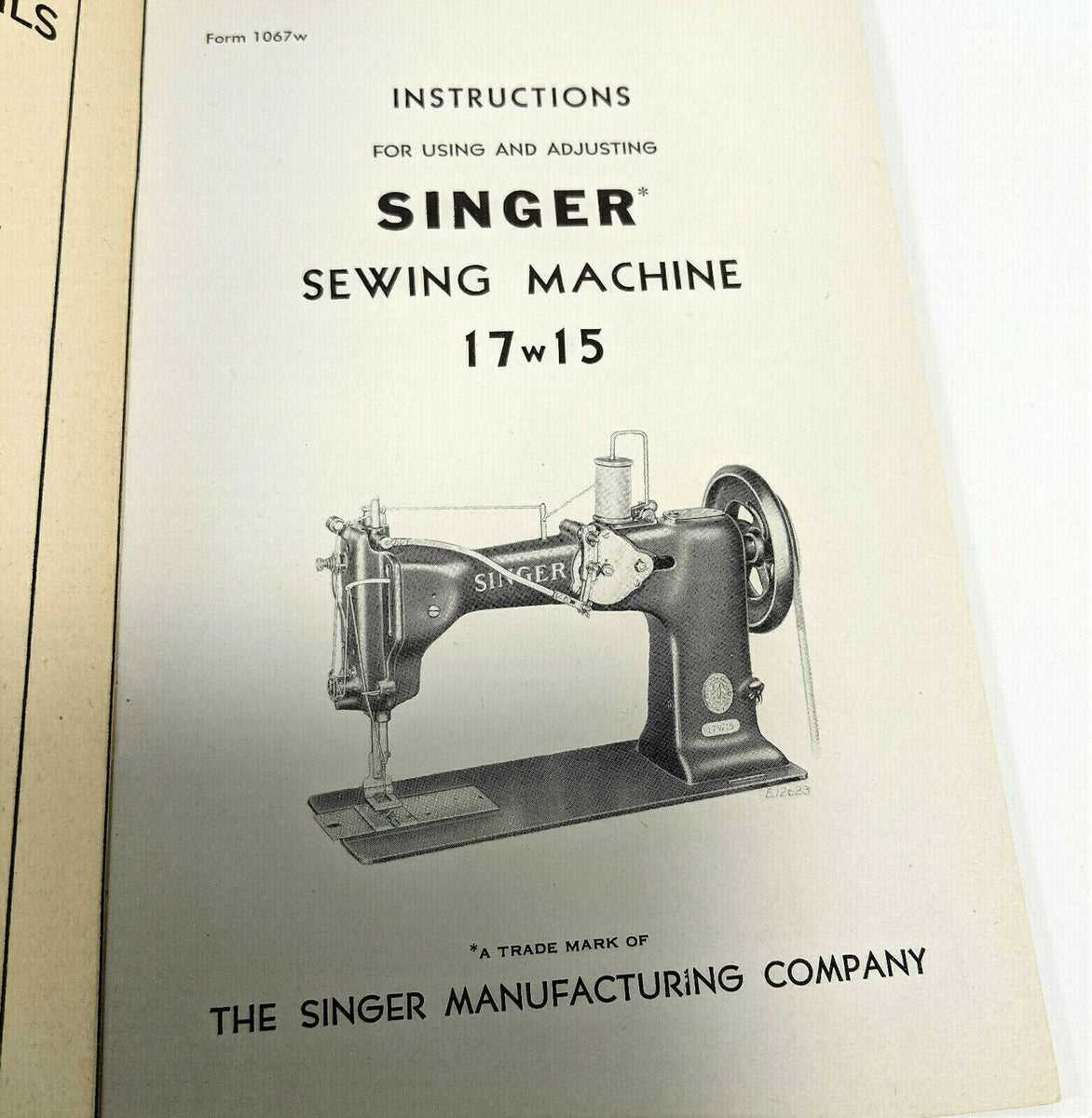

Understanding Your Singer Industrial Sewing Machine

Getting to know your heavy-duty stitching tool is essential for optimizing its performance and ensuring it meets your specific needs. This section will guide you through the key components and functionalities of the device, enabling you to make the most out of its capabilities. With a solid grasp of its design and features, you’ll be able to operate it more effectively and maintain it in excellent condition.

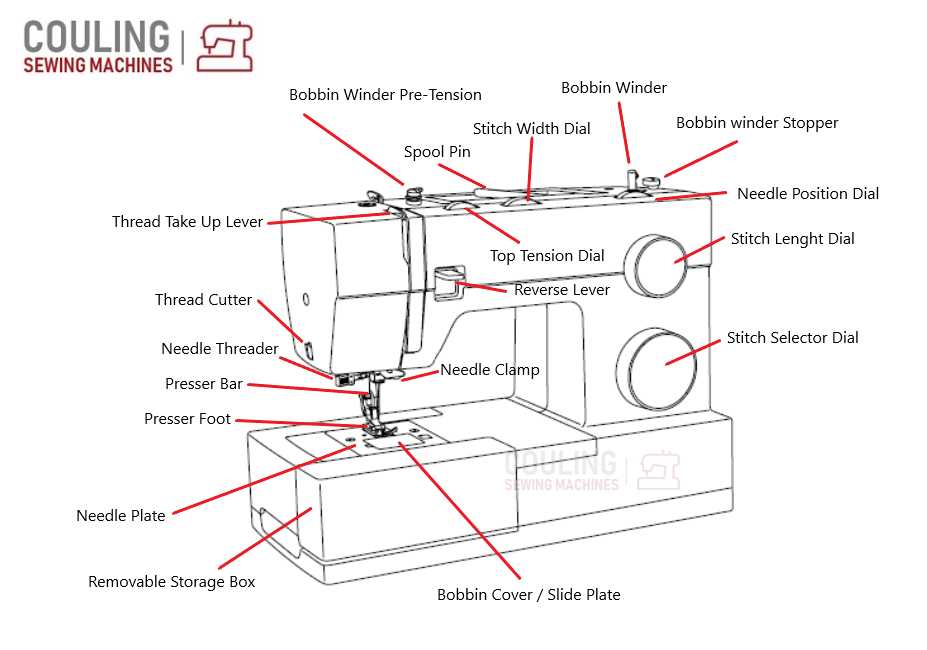

Key Components

Your high-performance stitching apparatus consists of several crucial parts that work together to deliver precise results. Familiarize yourself with the following components:

- Needle – This part pierces the fabric and forms stitches.

- Presser Foot – It holds the fabric in place during stitching.

- Feed Dogs – These grip and move the fabric through the mechanism.

- Bobbin – This small spool provides the lower thread for stitching.

- Thread Tension Adjuster – Regulates the tightness of the thread to ensure balanced stitches.

- Stitch Selector – Allows you to choose different types of stitches for various applications.

Basic Operations

Understanding the basic operations of your device will help you handle it more efficiently:

- Threading the Machine – Proper threading ensures smooth operation and quality stitching.

- Adjusting Tension – Balance the thread tension to avoid puckering or loose stitches.

- Using Different Stitches – Experiment with various stitch types for different fabric types and sewing tasks.

- Maintenance – Regularly clean and oil the device to keep it in good working order.

- Changing Needles and Bobbins – Replace these components as needed to maintain optimal performance.

By understanding these aspects, you will be better equipped to operate your advanced stitching tool effectively, ensuring you achieve the best results for your projects.

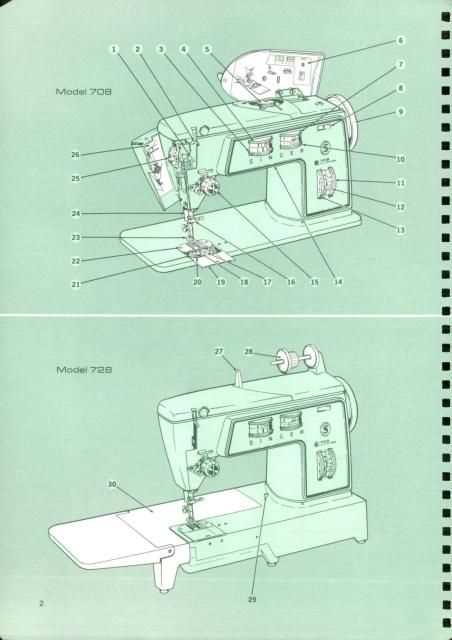

Basic Features and Components Overview

Understanding the fundamental elements and functionalities of a textile production device is crucial for efficient operation and maintenance. This section provides a concise overview of the essential attributes and components that define such a device, helping users grasp the core features and how they contribute to the overall performance.

Main Features

At the heart of this device are several key features designed to facilitate various tasks. These typically include mechanisms for adjusting thread tension, controlling stitch length, and ensuring precise alignment of fabrics. The ability to easily configure these settings enhances both versatility and accuracy in fabric manipulation.

Key Components

The primary components of this equipment consist of several integral parts, each serving a specific purpose. The needle assembly is crucial for creating stitches, while the bobbin system works in tandem with the needle to ensure consistent thread supply. Additionally, the feed mechanism moves the fabric through the device, allowing for seamless stitching. Understanding the function and maintenance of these parts is essential for optimal performance and longevity.

How to Set Up Your Sewing Machine

Preparing your stitching device for use involves a series of essential steps to ensure it operates smoothly and efficiently. This process is crucial for achieving the best results in your crafting projects and avoiding common pitfalls. Here, we outline the fundamental actions required to get your equipment ready for optimal performance.

Assemble the Components

Begin by gathering all parts of your apparatus. Typically, this includes the base, the needle holder, and any additional accessories. Follow the provided diagrams or guidelines to correctly attach each piece. Ensure all components are securely fastened to avoid any malfunction during use.

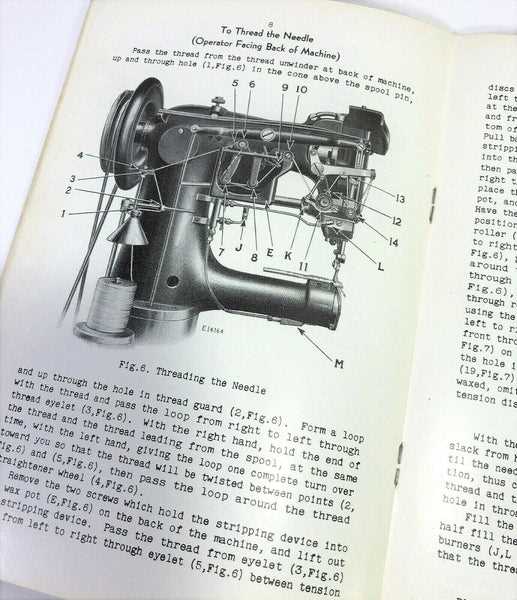

Thread the Device

Next, properly thread the needle and bobbin. Start by placing the spool of thread on its designated peg and guide the thread through the necessary channels, following the recommended path. Insert the bobbin into its compartment and make sure the thread is correctly engaged with the mechanism. Proper threading is critical for achieving clean and accurate stitches.

Lastly, adjust the tension settings according to the type of fabric you are working with. Consult the guidelines specific to your equipment for the optimal settings. Proper configuration of these elements will help prevent issues such as uneven stitching or thread breakage.

By following these steps, you can ensure that your device is set up correctly and ready to assist you in your creative endeavors.

Essential Maintenance Tips for Longevity

Proper upkeep is crucial to ensure that your equipment remains in excellent condition and performs efficiently over time. Regular maintenance not only extends the lifespan of your device but also minimizes the risk of unexpected malfunctions. By following a few simple guidelines, you can keep your gear running smoothly and avoid costly repairs.

Regular Cleaning

Keeping your equipment clean is fundamental to its longevity. Dust, lint, and other debris can accumulate and interfere with its operation. Here are some tips for effective cleaning:

- Use a soft brush or vacuum with a nozzle attachment to remove dust and lint from accessible parts.

- Wipe down surfaces with a dry cloth to prevent the buildup of dirt and grime.

- For stubborn residue, use a cloth lightly dampened with water or a mild cleaning solution, avoiding excess moisture.

Routine Lubrication

Lubricating moving parts is essential to ensure smooth operation and prevent wear and tear. Follow these steps for proper lubrication:

- Refer to the manufacturer’s recommendations for the types and amounts of lubricant to use.

- Apply lubricant to designated areas as specified, ensuring not to over-apply, which can attract dust.

- Regularly check and refill lubrication as needed, especially if the equipment is used frequently.

By adhering to these maintenance practices, you can enhance the performance and durability of your equipment, ensuring it serves you well for years to come.

Troubleshooting Common Sewing Issues

Addressing problems that arise during fabric manipulation can be a daunting task, especially for those who are not familiar with the intricacies of their equipment. Understanding how to identify and resolve these frequent challenges can significantly enhance your crafting experience and lead to better results. Below are some typical issues and their solutions to help you troubleshoot effectively.

Threading Problems

Issues with threading are among the most common and can lead to various complications. Here’s how to deal with them:

- Thread Breakage: Ensure that the thread is correctly threaded through the needle and bobbin. Check for any knots or frays in the thread that might cause it to snap.

- Uneven Stitching: Verify that the thread tension is correctly adjusted. Both upper and lower threads should be aligned properly to achieve even stitching.

- Thread Jamming: Inspect the bobbin case and make sure it is correctly positioned. Clean any lint or debris that might obstruct the thread flow.

Stitching Issues

When the stitches do not form as expected, it can be frustrating. Consider these potential fixes:

- Skipped Stitches: Check that the needle is not dull or damaged. Replacing the needle can often resolve this problem.

- Loose Stitches: Adjust the tension settings on your device. Ensure that the thread is properly seated in the tension discs.

- Fabric Puckering: Use appropriate presser feet for different fabric types and adjust the stitch length if necessary. Additionally, make sure the fabric is properly supported as it feeds through.

By addressing these common issues with the outlined solutions, you can troubleshoot effectively and enhance your crafting outcomes. Regular maintenance and proper setup will ensure smoother operation and better results in your projects.

Operating Instructions for Different Fabrics

Effectively managing various textiles requires an understanding of how different materials respond to stitching techniques. Each fabric has unique characteristics that influence how it should be handled to achieve the best results. Proper adjustment of settings and techniques can greatly impact the quality of the final product, making it essential to tailor your approach according to the fabric type.

Lightweight and Delicate Fabrics

When working with lightweight or delicate materials, such as chiffon or silk, it’s crucial to use a fine needle and a lighter thread to avoid damaging the fabric. Lower the tension settings to prevent puckering and adjust the stitch length to be slightly longer to accommodate the fabric’s softness. Additionally, consider using a stabilizer or tissue paper under the fabric to provide extra support during stitching.

Heavyweight and Thick Fabrics

For thicker materials, like denim or canvas, opt for a heavier needle and stronger thread to handle the increased density. Increase the stitch length to accommodate the bulk and adjust the tension to ensure even stitching. It may also be helpful to use a walking foot to help feed the fabric through more evenly and prevent bunching or shifting.

Advanced Techniques for Professional Results

Mastering advanced methods in textile crafting can elevate your projects from basic to exceptional. These refined techniques enhance precision, efficiency, and overall quality, providing a polished finish to your creations. Whether you’re tackling intricate patterns or aiming for flawless construction, these skills are essential for achieving professional outcomes.

Precision Stitching for Perfect Edges

Achieving flawless edges requires a steady hand and meticulous attention to detail. Utilize guides and markers to maintain uniformity and alignment throughout your work. Employing specialized presser feet designed for edge stitching can also help achieve crisp, clean lines. Regular calibration and maintenance of your equipment ensure consistent results and prevent potential issues during the crafting process.

Optimizing Tension and Feed for Seamless Results

Proper adjustment of thread tension and feed mechanisms is crucial for smooth and even stitching. Understanding how to fine-tune these settings based on fabric type and thread weight can prevent common problems such as puckering or skipped stitches. Experiment with different settings and test samples to find the optimal configuration for your specific project needs.