When acquiring a new device for crafting or repairs, one of the first challenges is learning to operate it effectively. Understanding the features and functionality of your equipment is crucial for achieving the best results, whether you’re creating something new or fixing a beloved item.

This guide aims to provide you with detailed insights and practical advice on how to get the most out of your new crafting companion. From setup to advanced techniques, every aspect of operation will be covered to ensure a smooth and enjoyable experience.

Mastering the basics is the first step towards becoming proficient with your tool. As you progress, you’ll discover a range of advanced features that allow for more complex and creative work. This guide is designed to be your go-to resource, offering tips and solutions for every stage of your journey.

Overview of the Singer 3343C Features

This versatile appliance combines user-friendly controls with advanced functionalities, catering to both beginners and experienced users. The model is equipped with various features designed to enhance precision and efficiency, offering a smooth and reliable operation for various textile projects.

Multiple Stitch Options: A variety of stitch patterns are available, allowing users to choose the most suitable one for their project, from basic designs to more intricate decorative options.

Adjustable Settings: Users can easily adjust stitch length and width, providing greater control and customization for each task.

Automatic Needle Threader: Simplifies the threading process, saving time and reducing eye strain, especially helpful for those who work on detailed tasks.

Compact and Portable: The design of this appliance makes it easy to transport and store, without compromising on the range of features offered.

Durable Construction: Built with robust materials, this model ensures long-term reliability, even with frequent use. Its sturdy frame also minimizes vibration during operation, leading to more precise results.

Accessories and Attachments: A variety of add-ons are included to expand the device’s capabilities, providing flexibility for different types of work, from basic adjustments to specialized techniques.

Overall, this tool provides a balanced mix of convenience and functionality, making it a valuable addition to any crafting workspace.

Setting Up Your 3343C

Before diving into the creative process, it’s crucial to prepare your equipment properly. This step-by-step guide will help you ensure everything is in place, allowing you to begin your projects smoothly and efficiently.

Unpacking and Initial Setup

- Carefully remove the device from its packaging, checking for any accessories or additional components.

- Place the unit on a stable, flat surface that provides adequate space for operation.

- Ensure the power cord is accessible and that the device is plugged into a secure outlet.

Threading the Needle

- Position the spool on the holder, making sure it rotates freely.

- Guide the thread through the tension mechanism, following the threading path as indicated.

- Thread the needle from front to back, ensuring the thread moves smoothly through the eye.

- Pull a small length of thread through the needle and leave it extended under the presser foot.

With your equipment properly configured, you’re now ready to explore various techniques and projects. Correct setup is essential for achieving precise results and ensuring your work progresses without interruptions.

How to Thread the Singer 3343C

Preparing your equipment for stitching requires careful attention to detail to ensure smooth and consistent operation. Proper threading is essential to avoid issues such as tangled threads or uneven stitches. Follow these steps to guide the thread through the system correctly, ensuring optimal performance during your projects.

Step 1: Setting Up the Spool

Begin by placing the spool on the designated holder at the top of the device. Ensure it is securely positioned to allow for even unwinding. Next, pull the thread from the spool and guide it through the first thread guide, which is typically located on the top left side of the apparatus.

Step 2: Guiding the Thread Through the Path

Continue leading the thread down towards the tension disks, making sure it passes between them smoothly. From there, bring the thread up to the take-up lever, ensuring it catches in the lever’s slot. Finally, guide the thread downwards again, threading it through the remaining guides leading to the needle. Insert the thread into the needle’s eye from front to back, leaving a small tail of thread behind.

Note: Always ensure the needle is at its highest position before beginning the threading process to make it easier and more effective.

Understanding the Stitch Selection Process

Choosing the right stitch is crucial for achieving the desired results in your projects. Each stitch type serves a specific purpose and impacts the final outcome in various ways. This process involves selecting the appropriate pattern and settings to match the fabric and the project’s requirements. By mastering this selection process, you ensure both functionality and aesthetic appeal in your creations.

Identifying the right stitch begins with understanding the fabric and its properties. Different materials require different stitching techniques to ensure durability and a polished finish. For instance, lightweight fabrics may need a delicate stitch to avoid puckering, while heavier materials might benefit from more robust stitching.

Exploring the available stitch options is essential for tailoring your choice to the specific needs of your project. Common stitches include straight, zigzag, and decorative variations, each with its unique application. Familiarity with these options allows you to customize your approach, enhancing both the functionality and design of your work.

Experimenting with stitch settings and adjustments can further refine your results. Tweaking tension, length, and width helps in optimizing the stitch performance according to the fabric and intended use. Practice and experience will guide you in selecting the best stitch for each unique scenario.

Maintaining Your Singer 3343C for Longevity

Proper upkeep is essential for ensuring the prolonged functionality and reliability of your textile crafting device. Regular care not only prevents common issues but also extends the life of the equipment. Following a few straightforward maintenance routines will keep your apparatus operating smoothly and efficiently.

Regular Cleaning and Lubrication

Routine cleaning and oiling are crucial for optimal performance. Dust and debris can accumulate in the moving parts, causing friction and wear. To prevent this, make sure to clean the device after each use and lubricate the essential components as specified by the manufacturer. Using appropriate cleaning tools and lubricants will help maintain the mechanism’s precision and functionality.

Proper Storage and Handling

Storing your equipment in a clean, dry environment is vital to avoid damage from moisture or dust. Always cover the device when not in use to protect it from environmental factors. Additionally, handling the apparatus with care during operation and transportation prevents accidental damage and ensures its longevity.

| Maintenance Task | Frequency |

|---|---|

| Cleaning | After each use |

| Lubrication | As per manufacturer’s instructions |

| Inspection for Wear | Monthly |

| Storage | Always |

Adhering to these maintenance practices will help ensure that your device remains in top condition, providing reliable service for many years to come.

Common Issues and Troubleshooting Tips

When working with your fabric tool, encountering issues is a normal part of the process. Understanding these common problems and knowing how to resolve them can help ensure a smoother experience. Below are some typical concerns you may face and practical advice on how to address them.

- Thread Jamming: This issue often arises when the thread gets tangled or is not threaded properly. To resolve this:

- Check the threading path to ensure it’s correctly set up.

- Verify that the thread is not caught in any parts of the device.

- Re-thread the needle and bobbin, and adjust the tension if necessary.

- Needle Breaking: A broken needle can be caused by various factors, including incorrect needle type or improper handling. To prevent this:

- Use the appropriate needle for the fabric type.

- Ensure the needle is properly inserted and tightened.

- Do not force the fabric through the needle; guide it gently.

- Uneven Stitching: This issue might occur due to incorrect settings or feeding issues. To fix this:

- Check the stitch length and width settings.

- Ensure the fabric is fed evenly and not bunching up.

- Inspect the feed dogs to ensure they are functioning correctly.

- Skipping Stitches: Skipping stitches can result from various problems, including needle issues or thread tension. To address this:

- Examine the needle for damage and replace if necessary.

- Adjust the thread tension to match the fabric and thread type.

- Ensure the needle is the correct size for your project.

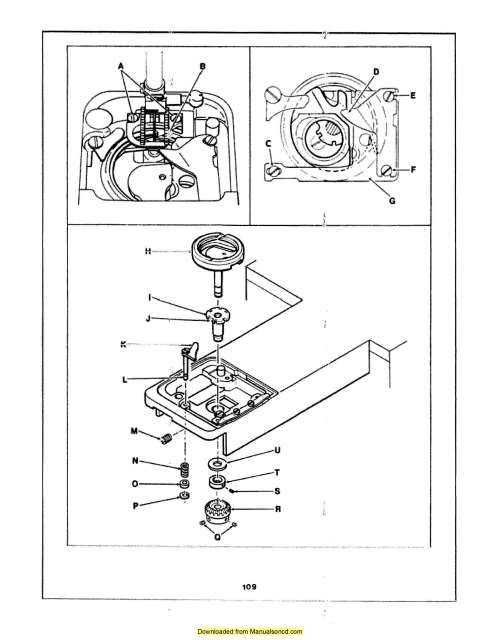

- Bobbin Issues: Problems with the bobbin can disrupt your work. To troubleshoot:

- Ensure the bobbin is correctly inserted and wound evenly.

- Check for any obstructions in the bobbin area.

- Replace the bobbin if it’s worn or damaged.

By following these guidelines, you can address many of the common problems that arise and continue working with confidence. Regular maintenance and proper handling are key to keeping your fabric tool in optimal condition.