Welcome to an in-depth exploration of your textile apparatus, designed to enhance your crafting experience. This section provides essential insights into operating and maintaining your device, ensuring you achieve the best results in your fabric projects.

By delving into this guide, you will gain a clear understanding of the equipment’s functionality and features. This resource aims to offer practical advice and detailed steps to help you navigate the various settings and adjustments, making your sewing endeavors more efficient and enjoyable.

Whether you’re a seasoned professional or a beginner, this guide is crafted to support you in mastering your textile device. From setup instructions to troubleshooting tips, you’ll find everything you need to optimize your usage and ensure seamless operation.

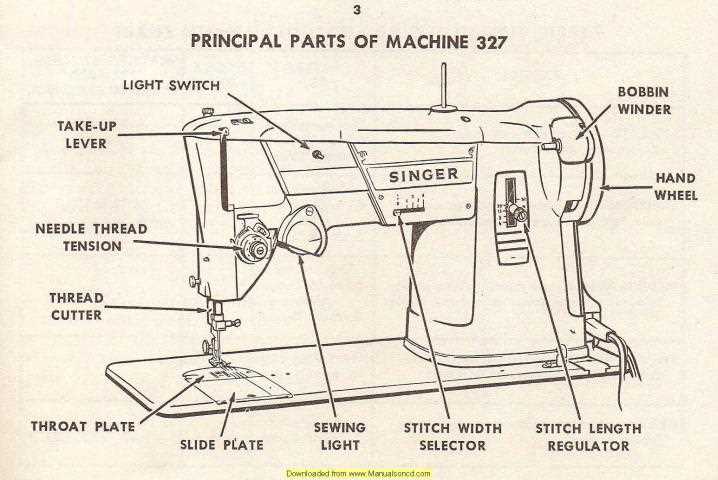

Features and Specifications

Understanding the attributes and technical details of a particular textile device can greatly enhance its usage. This section delves into the distinctive characteristics and technical parameters that define the performance and capabilities of the apparatus in question. By familiarizing yourself with these aspects, you can make informed decisions and fully leverage its potential.

The device boasts a range of features designed to facilitate a variety of tasks. Among these are multiple operational modes, which allow for versatility in handling different types of fabric and stitching requirements. Additionally, the inclusion of various built-in features ensures that users have access to advanced functionalities, improving both ease of use and the quality of results.

In terms of specifications, the apparatus is equipped with precise controls and settings that cater to diverse needs. Its mechanical and electronic components are engineered to offer reliable performance and durability. Key technical details include stitch types, speed settings, and adjustment capabilities, which collectively contribute to its overall efficiency and effectiveness.

Setting Up Your Sewing Machine

Getting your new crafting device ready for use involves a series of essential steps. This preparation ensures smooth operation and optimal performance. By following these guidelines, you will establish a solid foundation for your upcoming projects.

- First, choose a stable and well-lit workspace. This will help you focus and handle the device with ease.

- Unpack all components carefully and place them on a clean surface. Verify that you have all necessary parts and accessories.

- Refer to the basic assembly instructions to put together the unit. Ensure all parts are securely attached according to the provided guidelines.

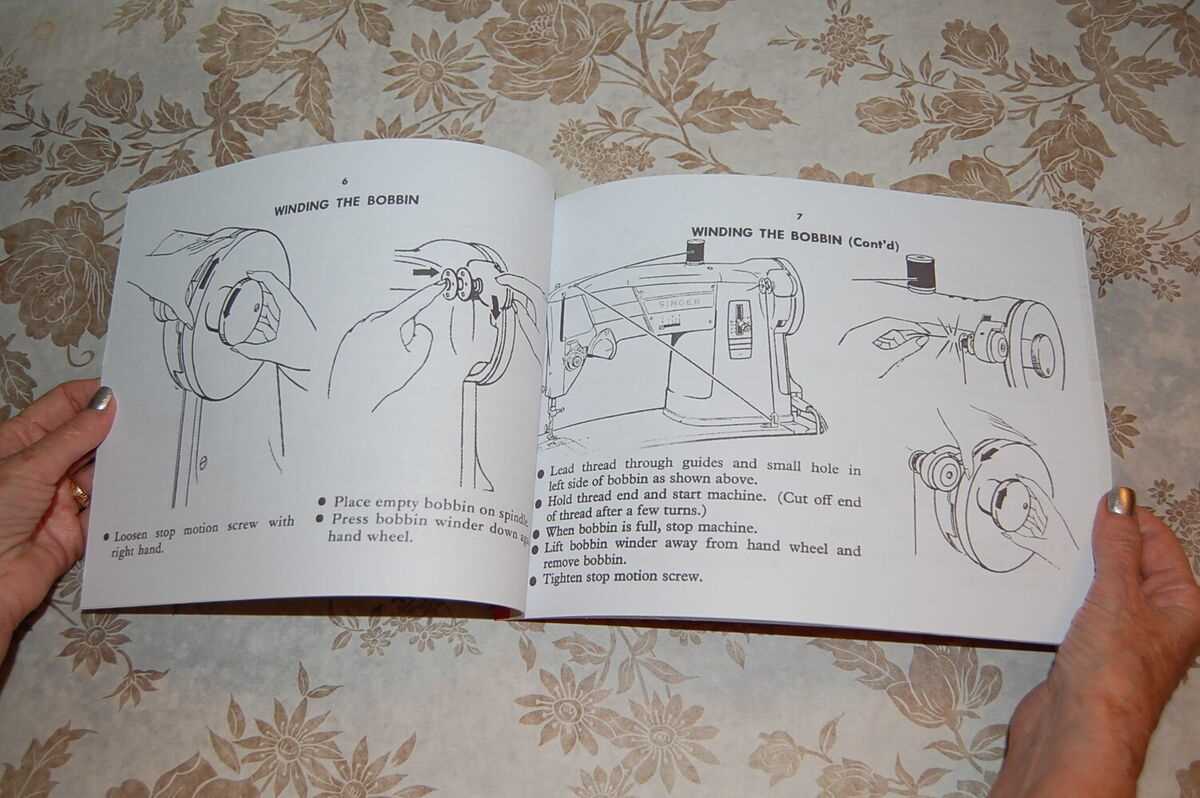

- Thread the device as per the recommended threading path. This usually involves placing the thread spool on the designated holder and guiding the thread through the various mechanisms.

- Adjust the tension settings to suit your fabric type. Proper tension will prevent issues like uneven stitching or thread breakage.

- Install the appropriate needle and foot attachments. Make sure they are compatible with the type of fabric and project you are working on.

- Perform a test run on a scrap piece of fabric to check the stitching and make necessary adjustments.

- Read through the operational guidelines to familiarize yourself with the basic functions and settings of the device.

By meticulously following these setup steps, you will ensure that your equipment is ready for effective and enjoyable use.

Initial Assembly and Adjustments

Setting up and fine-tuning your new equipment involves a few essential steps to ensure optimal performance. This process includes assembling various components and making precise adjustments to align the device according to your needs. By following these guidelines, you can achieve smooth and efficient operation right from the start.

Assembling the Components

Begin by carefully assembling each part according to the provided guidelines. Ensure all pieces are correctly fitted and securely attached. This preliminary setup is crucial for the machine’s functionality and longevity. Pay close attention to each component’s placement to avoid misalignment.

Making Precise Adjustments

Once the assembly is complete, proceed with fine-tuning. Adjust the settings to align the device with your specific requirements. This step involves calibrating various aspects to ensure accurate and reliable performance. Proper adjustments will enhance the overall efficiency and effectiveness of your equipment.

Basic Sewing Techniques

Mastering fundamental techniques is essential for creating high-quality fabric projects. These skills form the foundation for successful craftsmanship, whether you’re stitching garments, accessories, or home decor items. Understanding the basics of thread manipulation, stitch formation, and fabric handling allows for greater precision and efficiency in your work.

Threading and Stitching Fundamentals

Proper threading of the tool is crucial for smooth operation. Ensure that the thread is correctly placed through the necessary guides and tension mechanisms. Different types of stitches serve various purposes, from straight stitches for simple seams to zigzag stitches for stretchable fabrics. Experiment with different stitches to understand their effects and applications.

Fabric Handling and Seam Finishing

Effective handling of fabric involves managing its movement and alignment during stitching. Techniques such as pinning, basting, and using seam allowances help maintain accuracy and prevent shifting. Additionally, finishing the edges of seams helps prevent fraying and gives a professional appearance to the finished product.

Maintenance and Troubleshooting Tips

Proper upkeep and timely problem-solving are essential for ensuring long-lasting performance and optimal functionality. Regular maintenance not only extends the lifespan of the device but also helps in avoiding common issues that may disrupt operation. In this section, we will explore essential care practices and provide solutions to frequent operational challenges.

Regular Maintenance Practices

To maintain optimal performance, it’s important to routinely clean and lubricate the device. Dust and debris can accumulate over time, leading to potential mechanical issues. Use a soft brush or compressed air to remove any lint or particles from moving parts. Additionally, applying a few drops of oil to specific components will reduce friction and prevent wear.

Common Issues and Solutions

Understanding common problems can help in quickly identifying and fixing them. Here is a list of frequent issues along with their possible causes and solutions:

| Issue | Possible Cause | Solution |

|---|---|---|

| Irregular Operation | Accumulated dust or lack of lubrication | Clean moving parts and apply oil as needed |

| Unexpected Noise | Loose screws or worn-out components | Tighten screws and replace damaged parts |

| Performance Hiccups | Incorrect settings or improper threading | Double-check settings and ensure proper threading |

| Stitch Inconsistencies | Improper needle size or tension settings | Adjust needle size and reconfigure tension settings |

By following these maintenance steps and understanding how to troubleshoot common issues, users can ensure that their device remains in excellent working condition, providing reliable performance for years to come.