When it comes to mastering a vintage piece of equipment, understanding its nuances is key to ensuring its optimal performance. This timeless apparatus, known for its reliability and ease of use, has been a favorite among enthusiasts and professionals alike. The following guide is designed to provide a thorough overview of this beloved model, offering valuable insights to help users get the most out of their experience.

Exploring the Key Features of this classic device allows us to appreciate its unique capabilities. Each element, from its construction to its operation, is thoughtfully designed to provide a seamless experience. By delving into the specifics, users can discover how to best utilize this tool’s potential, enhancing both efficiency and creativity in their projects.

With a focus on practical advice and clear explanations, this guide aims to be an essential companion for both new users and seasoned operators. From setup to maintenance, every aspect is covered to ensure a smooth and enjoyable journey with this enduring classic. Let us embark on this explo

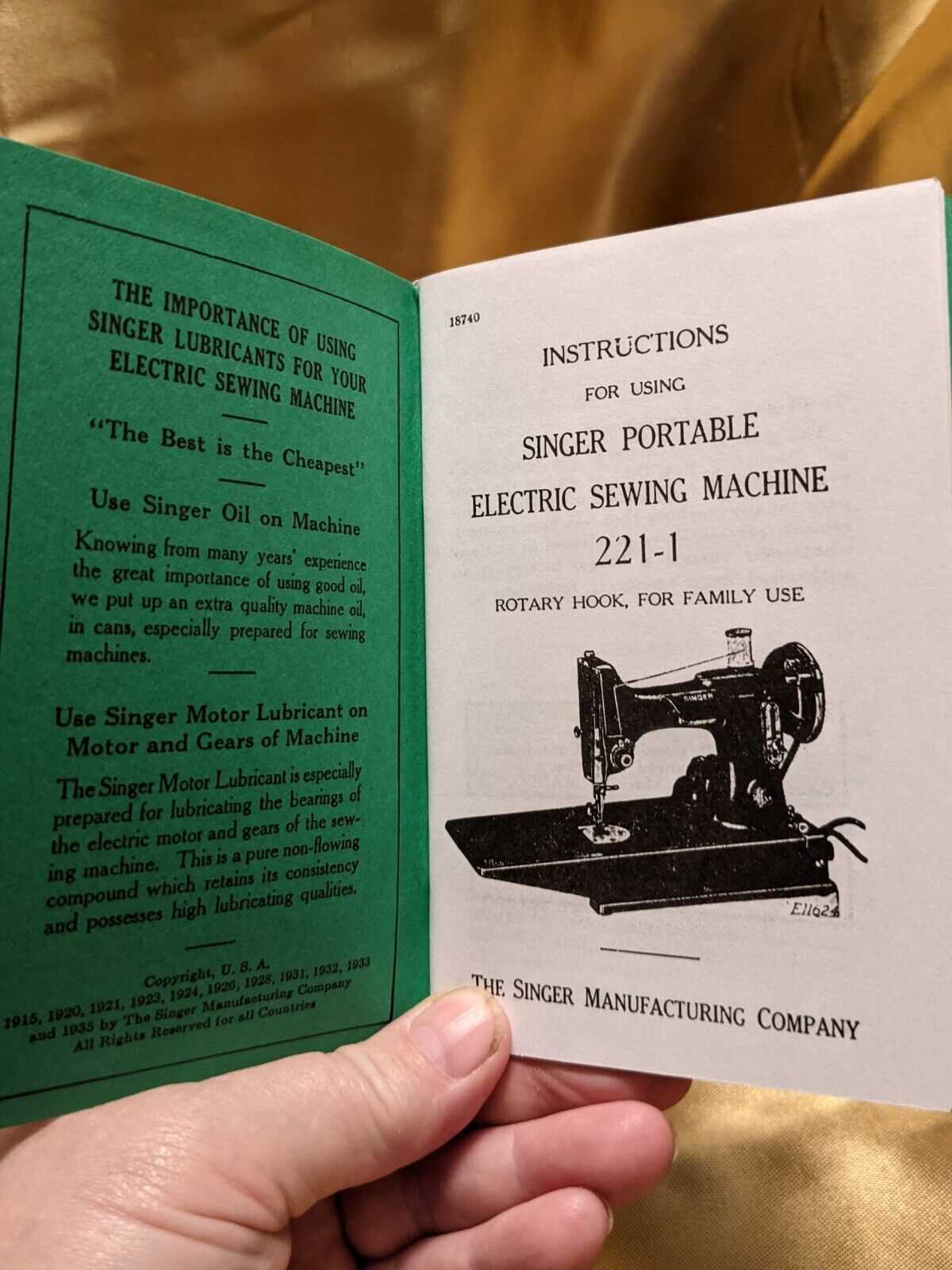

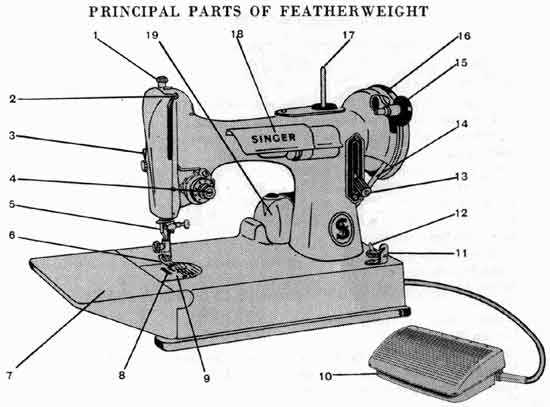

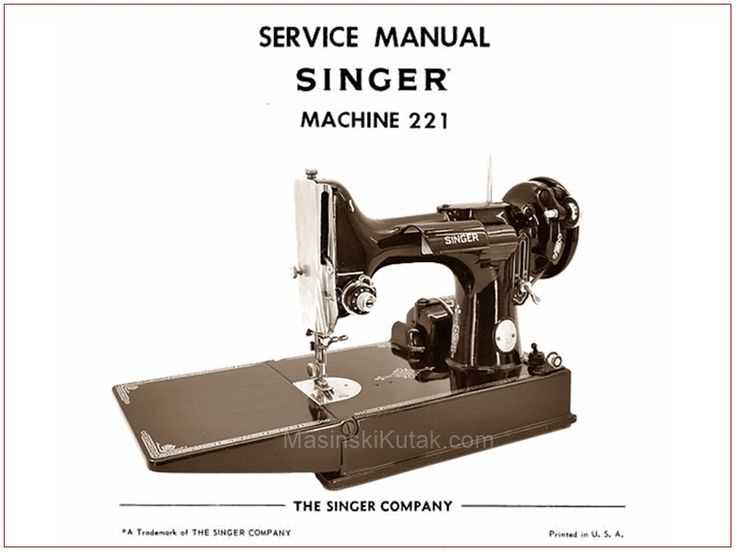

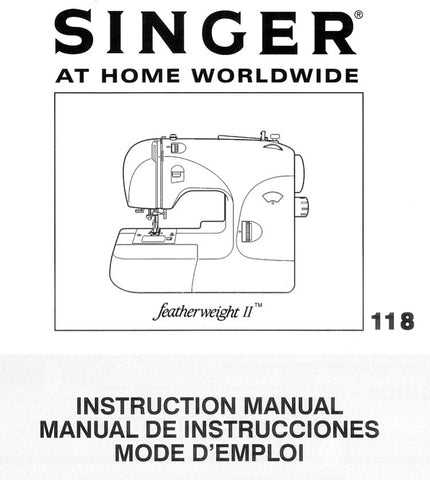

Overview of the Singer Featherweight Features

This classic model has captivated enthusiasts with its timeless design and reliable functionality. A perfect blend of form and function, it offers a variety of attributes that cater to both newcomers and experienced users, making it a beloved choice among hobbyists and professionals alike.

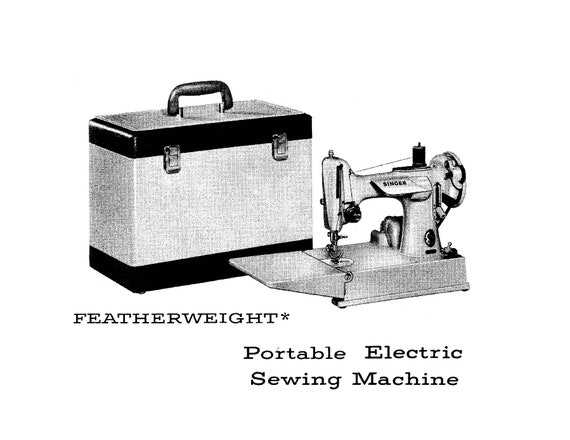

- Compact Design: Its lightweight structure ensures easy portability, making it an ideal option for those who need a versatile tool that can be moved effortlessly from one place to another.

- Durable Construction: Crafted from high-quality materials, this model is built to last, offering years of dependable performance with minimal maintenance.

- Ease of Use: With a straightforward setup and user-friendly controls, it is perfect for anyone looking to quickly start projects without complicated preparation.

- Quiet Operation: Its smooth and quiet functioning is a standout feature, allowing for a peaceful experience, whether working in a shared space or at home.

- Precision Work: Known for its exceptional accuracy, it delivers fine, consistent results, which is especially valuable for intricate designs and d

Understanding Key Components of the Machine

Grasping the essential parts of this device is crucial for optimal usage and maintenance. Each component plays a specific role, contributing to the overall functionality and efficiency. By familiarizing yourself with these elements, you can ensure smoother operation and address any issues more effectively.

Main Structural Elements

- Base Unit: The foundation that provides stability and supports all other parts. It is designed to endure the vibrations and forces during operation.

- Drive Mechanism: This component powers the movement, translating energy into the necessary motion for the tool’s operation. It includes various gears and belts that work in harmony to maintain precision.

- Control Panel: The interface through which you can manage the settings and adjust functions. It offers various knobs and levers to tailor the device’s performance to your needs.

Functional Components

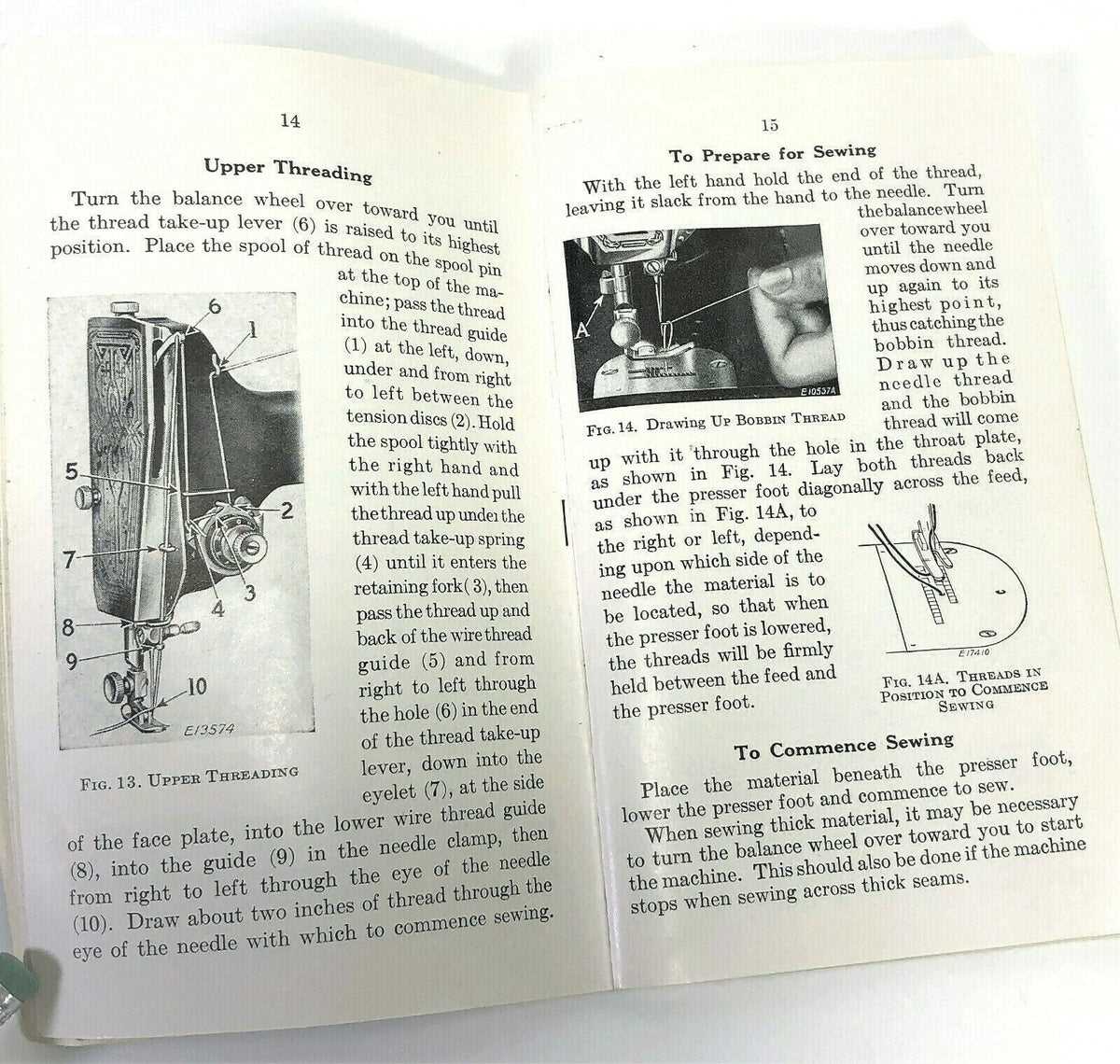

- Threading System: A crucial part responsible for guiding the filament through the device smoothly. This includes guides, tension discs, and other elements that work together to prevent tangling or breakage.

- Needle Assembly: Comprising the needle, holder, and

Setting Up Your Sewing Machine Correctly

Proper preparation of your device is crucial to ensure smooth operation and high-quality results. Taking the time to arrange all components correctly will save you from potential issues and enhance your experience. Follow the steps below to make sure your equipment is ready to use efficiently.

Positioning Your Equipment

Start by placing your device on a stable, flat surface. Ensure that the area is well-lit and free from obstructions. The right position not only provides comfort but also prevents unnecessary strain during prolonged use. Adjust the height of your workspace so that your hands are level with the device, promoting good posture and reducing fatigue.

Connecting the Essential Parts

Once positioned, connect the necessary parts securely. Attach the power cord to a nearby outlet and ensure it is well-fitted to avoid interruptions. Insert the foot pedal correctly and test its responsiveness. Proper connection of these elements is vital to ensure smooth functionality and control over your equipment.

With these steps completed, your device is now ready for use. Proper setup enhances efficiency and extends the lifespan of your equipment, making the preparation process a key part of your workflow.

Step-by-Step Guide to Initial Setup

Getting started with your new tool can seem daunting, but with a clear sequence of actions, you can easily prepare your device for optimal performance. This section will walk you through each phase to ensure everything is ready for your first project.

Unpacking and Organizing Components

Begin by carefully removing all elements from the packaging. Place each part on a flat surface, ensuring that nothing is missing or damaged. Take a moment to familiarize yourself with each component and its purpose. It’s crucial to have a clean and organized workspace to prevent any pieces from getting lost or misplaced.

Connecting the Device and Powering On

Once all parts are accounted for, position the main unit on a stable, flat surface. Attach the necessary connections, including any power adapters or additional elements. Ensure all cables are securely connected. When everything is in place, switch on the device using the main power button. Pay attention to any indicators or sounds that confirm the device is functioning correctly.

Following these steps will help you smoothly set up your equipment and prepare it for use, making your initial experience

Maintenance Tips for Longevity

To ensure your device remains in optimal condition and serves you well for years to come, regular care and maintenance are crucial. Proper upkeep not only prevents breakdowns but also enhances performance and extends the lifespan of your equipment.

Regular Cleaning

Keep the surfaces and internal components clean to avoid dust and debris accumulation. Periodically wipe down external parts with a soft, dry cloth. For internal areas, use a gentle brush to remove particles that might affect functionality.

Lubrication

Apply appropriate lubricants to moving parts according to the manufacturer’s recommendations. This prevents wear and tear and ensures smooth operation. Be sure to use only recommended lubricants to avoid damage.

Adhering to these simple yet effective maintenance practices will help maintain the efficiency and reliability of your equipment.

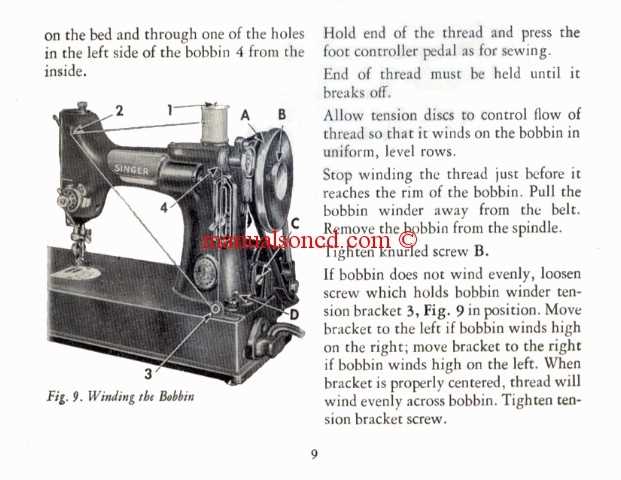

Regular Cleaning and Lubrication Techniques

Maintaining the longevity and smooth operation of your equipment involves periodic cleaning and applying the right lubrication. Proper care ensures optimal performance and prevents potential issues that can arise from neglect. Regular upkeep helps in keeping the internal components free from debris and well-lubricated, which is essential for trouble-free functionality.

Cleaning Procedures

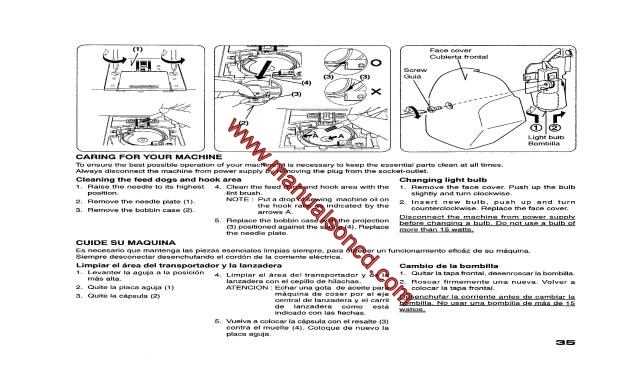

Start by removing any dust or lint accumulated around and inside the unit. Use a soft brush or compressed air to dislodge particles from hard-to-reach areas. Ensure that the cleaning tools are gentle to avoid damage to delicate parts. Regularly inspect and clean the feed dogs, needle plate, and bobbin case to maintain efficiency and prevent jamming.

Lubrication Techniques

Apply lubricant specifically designed for this type of equipment to the moving parts to reduce friction and wear. Focus on key areas such as the needle bar, presser foot mechanism, and shuttle race. Follow the manufacturer’s recommendations for the type and amount of lubricant to use, as over-lubrication can attract dust and cause buildup.

Troubleshooting Common Issues

When working with precision equipment, encountering operational difficulties is not uncommon. Addressing these problems promptly can ensure optimal performance and longevity. This section aims to provide solutions for frequent malfunctions that users might face, offering practical advice to resolve them effectively.

Issue 1: Machine Not Starting

If the equipment fails to power on, first check the connection to the power source. Ensure that the cord is securely plugged in and that the power switch is turned on. Additionally, inspect the fuse or circuit breaker to confirm they are functioning correctly. If these components are in order and the problem persists, the issue might lie within the internal wiring or switch mechanism, requiring further inspection by a qualified technician.

Issue 2: Uneven Stitching

Uneven stitching can be caused by several factors, including incorrect threading or improper tension settings. Begin by rethreading the unit, ensuring that both the upper and lower threads are correctly placed. Adjust the tension settings according to the fabric type and thread used. If the problem continues, examine the needle for any damage or misalignment and replace it if necessary.

Identifying and Solving Sewing Problems

When working with a compact and reliable stitching device, encountering issues during operation can be quite common. Recognizing and addressing these challenges effectively ensures a smooth and enjoyable experience. This section delves into various obstacles one might face, providing insight into troubleshooting and resolving these problems with ease.

Issue Possible Cause Solution Skipped Stitches Incorrect needle type or size, or tension issues Ensure you are using the correct needle for the fabric and adjust tension settings accordingly Thread Bunching Incorrect threading or bobbin issues Re-thread the top and bobbin threads, making sure they are correctly positioned Uneven Stitching Uneven feed or incorrect presser foot pressure Adjust the feed dogs and presser foot pressure to ensure even fabric feeding Fabric Jamming Improper fabric handling or incorrect needle Use the appropriate needle for the fabric type and ensure proper fabric guidance