Delving into the essentials of operating a vintage textile apparatus reveals a rich history of craftsmanship and functionality. This guide aims to illuminate the fundamental aspects of utilizing such a device, ensuring you can effectively harness its capabilities.

Mastering the intricacies of this device requires familiarity with its various components and operational techniques. By exploring each element and its purpose, you’ll gain the confidence to manage and maintain your apparatus with ease.

Whether you’re reviving an old hobby or discovering a new interest, understanding the core principles of this historical tool can enhance your experience and appreciation. Embrace the learning process to fully benefit from the unique features of this classic equipment.

Understanding Your Vintage Singer Sewing Machine

Delving into the mechanics of your classic textile tool reveals the intricacies of its design and functionality. Such a device represents a blend of craftsmanship and engineering, offering a glimpse into the past while still proving useful in contemporary settings. This guide aims to provide insight into how to operate and maintain this cherished artifact, ensuring it continues to serve its purpose effectively.

Key Features and Components

Every vintage textile apparatus boasts a set of distinctive attributes and components. Recognizing these elements can greatly enhance your familiarity with the equipment. Pay attention to the various knobs, levers, and dials that control the functions and settings of your device. Understanding their roles will enable you to make precise adjustments and perform necessary tasks with ease.

Maintenance Tips

Proper upkeep is crucial to extending the lifespan of your cherished apparatus. Regular cleaning and oiling of the internal parts are essential practices to keep the device in optimal working condition. Ensure that you follow specific procedures for maintenance to avoid any potential issues and preserve the machine’s functionality for years to come.

Key Features of Vintage Models

Vintage sewing devices, renowned for their craftsmanship and durability, offer a range of distinctive characteristics that set them apart from their modern counterparts. These classic implements are celebrated for their robust construction and the meticulous attention to detail evident in their design. Each feature reflects a commitment to quality and functionality, making these items treasured by collectors and enthusiasts alike.

Craftsmanship and Design

The hallmark of these vintage implements lies in their exceptional craftsmanship. Each component is meticulously engineered to ensure longevity and reliability. The elegant design often incorporates intricate details and high-quality materials, showcasing a level of artistry that is less common in contemporary models.

Mechanical Simplicity

Another notable aspect is the mechanical simplicity that characterizes these early models. Unlike modern devices, these vintage items often feature straightforward mechanisms that are easy to maintain and repair. This simplicity not only enhances their durability but also makes them accessible for users who appreciate hands-on maintenance.

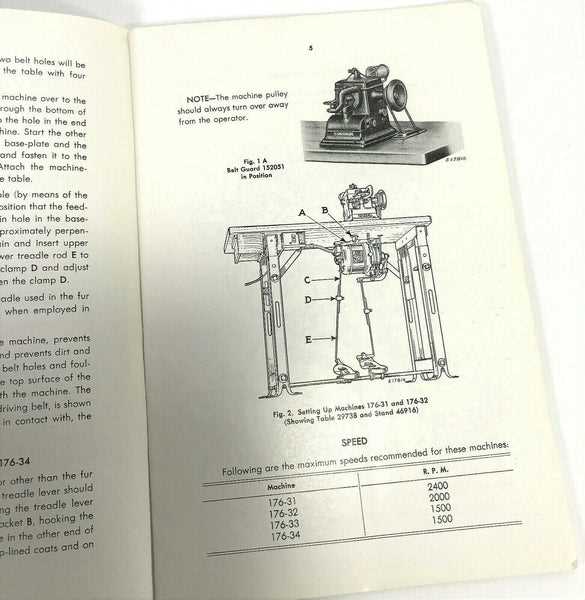

Operating Instructions for Singer Machines

Understanding how to properly utilize a vintage stitching device involves familiarizing yourself with its essential functions and features. This section provides an overview of how to operate these classic units efficiently, ensuring they perform optimally while meeting your needs.

Basic Operations

Begin by setting up the apparatus on a stable surface. Make sure the unit is securely plugged in and the power switch is in the ‘on’ position. Adjust the tension settings according to the fabric type you are working with. It’s crucial to test the stitching on a scrap piece of material to ensure everything is functioning as expected.

Maintenance and Care

Regular upkeep is key to prolonging the lifespan of your device. Clean the machine after each use to remove dust and lint that may accumulate. Lubricate the moving parts as instructed to maintain smooth operation. Always refer to the specific guidelines for the model you are using to perform proper maintenance.

Maintaining Your Vintage Sewing Machine

Preserving the functionality and appearance of an antique textile apparatus requires regular care and attention. Proper upkeep not only enhances its longevity but also ensures smooth operation and maintains its historical value. This section provides essential tips for keeping such equipment in optimal condition.

Routine Cleaning

Regular cleaning is crucial to prevent dust and fabric debris from accumulating, which can impair the performance of your apparatus. Use a soft cloth to wipe down the exterior and a brush to clear out any dust from the internal components. Avoid using abrasive materials that could damage the surface.

Lubrication and Adjustment

Lubrication is key to keeping moving parts functioning smoothly. Apply a few drops of sewing machine oil to the designated areas as specified in the device’s guidelines. Ensure that all screws and adjustments are tight to avoid misalignment, which could affect the operation.

| Component | Maintenance Task | Frequency |

|---|---|---|

| Exterior | Wipe down with a soft cloth | Weekly |

| Internal Parts | Brush away dust | Monthly |

| Moving Parts | Apply sewing machine oil | Every 6 months |

| Screws and Adjustments | Tighten and check alignment | Every 6 months |

Common Issues and Troubleshooting Tips

Understanding and addressing frequent challenges with vintage stitching devices can enhance their longevity and performance. This section explores prevalent problems users might encounter and provides practical solutions to resolve them effectively. By following these guidelines, you can ensure smoother operation and minimize interruptions during use.

Thread Jamming and Breakage

One common issue with older stitching tools is thread jamming or snapping. This problem often arises from improper threading, tension imbalances, or accumulated debris. To rectify this, first, check the threading paths to ensure they are correctly aligned. Adjust the tension settings as needed, and regularly clean the machine to remove any lint or residue that might obstruct the thread flow.

Inconsistent Stitch Quality

Inconsistent stitching can result from several factors, including needle issues, tension problems, or incorrect feed settings. Examine the needle for any signs of damage or dullness and replace it if necessary. Verify that the tension settings are appropriately adjusted for the fabric type and ensure that the feed mechanisms are functioning correctly. Regular maintenance and adjustments can help achieve uniform stitch quality.

Finding Replacement Parts and Accessories

Locating suitable components and additional items for vintage devices can be a rewarding yet challenging task. These older models often require specific parts that may no longer be readily available in mainstream stores. Understanding where to search and how to verify compatibility is crucial for maintaining the functionality and longevity of these cherished items.

Exploring Specialty Retailers

One effective way to find replacement components is by visiting specialty retailers who focus on vintage equipment. These shops often have extensive inventories of hard-to-find parts and can offer valuable expertise in identifying the right items. Additionally, many of these retailers maintain online catalogs, making it easier to browse and order parts from the comfort of your home.

Utilizing Online Resources

The internet is a treasure trove of resources for locating specific parts and accessories. Online forums, auction sites, and dedicated communities can provide leads on where to find the exact items you need. Engaging with these communities can also offer insights and recommendations from other enthusiasts who have navigated similar challenges.