Working with high-performance tools requires not only skill but also a deep understanding of the device’s features. When handling robust equipment designed for precise tasks, it is essential to grasp the key elements that contribute to its effective operation. Knowing how to operate such a tool efficiently can greatly enhance both productivity and safety.

In this guide, we will explore various aspects of using a powerful woodworking device, focusing on the best practices for achieving smooth and accurate results. From setup to maintenance, we will cover essential tips to ensure you can make the most out of this versatile tool.

Whether you are a seasoned professional or a beginner, this guide aims to provide valuable insights that can help you work more confidently and effectively with your equipment. Let’s delve into the details that will empower you to harness the full potential of your tool.

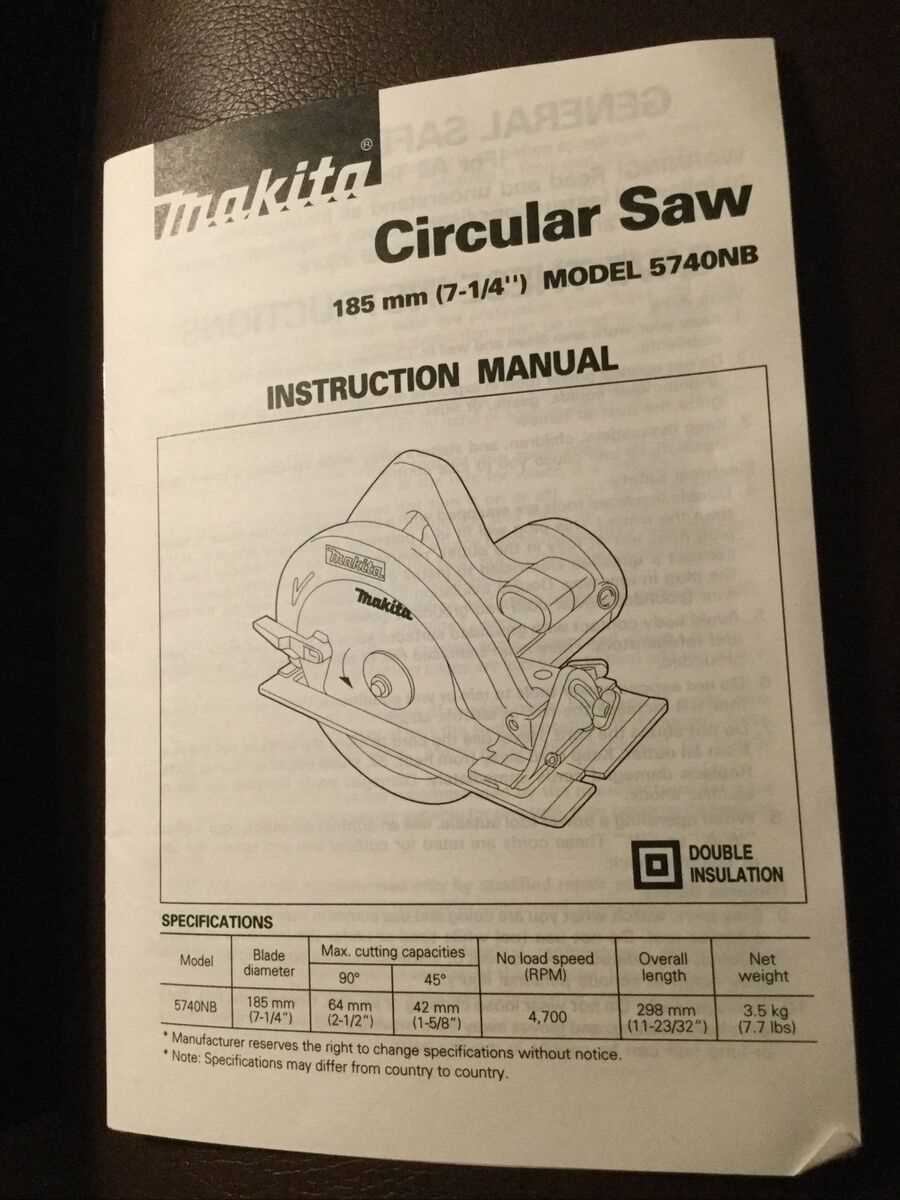

Overview of the Circular Saw’s Key Features

This section provides a comprehensive look at the essential attributes that define the functionality and performance of this power tool. Understanding these features will help users maximize the tool’s potential for various cutting tasks.

The device is designed with precision in mind, offering adjustable settings that allow for fine-tuning the cutting depth and angle. This ensures versatility, enabling it to handle a wide range of materials with ease.

Safety is also a priority, with built-in mechanisms that reduce the risk of accidents during use. Additionally, the tool is equipped with an ergonomic handle that enhances user comfort, making prolonged operation less strenuous.

Durability is another standout feature, with high-quality construction that ensures the tool can withstand heavy use over time. This reliability is complemented by its efficient motor, which delivers consistent power for smooth and precise cuts.

Lastly, the tool includes convenient features such as a dust collection system, which helps maintain a clear working area, and easy-to-access controls, allowing users to make adjustments quickly and efficiently.

Safe Handling Techniques and Best Practices

Understanding the essential principles of using powerful cutting tools can significantly reduce the risk of injury and ensure efficient work. By adhering to recommended procedures and developing good habits, users can achieve precise results while maintaining a secure working environment.

| Proper Grip | Always maintain a firm hold on the tool with both hands to enhance stability and control during operation. |

| Work Area Preparation | Ensure the workspace is clean and well-lit, free of any obstructions that might interfere with the task. |

| Personal Protective Equipment (PPE) | Wearing appropriate safety gear, such as goggles and gloves, is crucial for protecting yourself from potential hazards. |

| Tool Inspection | Regularly check the tool for any signs of damage or wear, and make sure all components are securely fastened before use. |

| Cutting Direction | Always guide the tool in the correct direction, and avoid forcing it through the material to prevent kickbacks. |

Step-by-Step Guide to Blade Installation

Ensuring the proper attachment of the cutting disc is crucial for both performance and safety. This guide provides a comprehensive approach to securely affixing the disc, allowing for efficient and smooth operation during use.

Step 1: Begin by disconnecting the device from any power source to avoid accidental activation. Safety should always be the first priority.

Step 2: Remove the blade guard by loosening the appropriate screws or lever. This will expose the arbor, making it easier to remove the existing blade.

Step 3: Use a wrench to loosen the arbor nut by turning it in the correct direction, which is typically counterclockwise. Once loosened, remove the old blade carefully.

Step 4: Place the new cutting disc onto the arbor, ensuring that the teeth are oriented correctly for the intended use. Verify that the blade sits flat and evenly on the arbor.

Step 5: Tighten the arbor nut back into place, securing the new blade firmly. Be cautious not to over-tighten, as this could cause damage.

Step 6: Reattach the blade guard and ensure all components are securely in place. Double-check that the guard moves freely and does not obstruct the disc.

Step 7: Reconnect the power source and perform a test run

Maintaining and Sharpening the Saw Blade

Proper care and routine sharpening of the cutting edge are essential for optimal performance and longevity. By regularly maintaining the blade, you ensure smooth and accurate cuts while extending its lifespan. This process involves careful inspection, cleaning, and the precise honing of the cutting teeth to restore sharpness.

To begin, it’s important to clean the blade thoroughly, removing any debris or buildup that can affect its efficiency. After cleaning, inspect the edges for any signs of wear or damage. If the teeth appear dull or uneven, sharpening is necessary to bring them back to their original state.

Sharpening can be done manually using a file or with the aid of a specialized tool designed for this purpose. Regardless of the method chosen, it’s crucial to maintain a consistent angle and pressure to achieve uniform sharpness across all teeth. After sharpening, double-check the blade for any remaining imperfections and ensure it is ready for use.

Troubleshooting Common Operational Issues

When dealing with machinery, it’s essential to address potential challenges that might arise during use. Identifying and resolving common problems can ensure optimal performance and longevity of the equipment.

Power-Related Problems

- Check the power source: Ensure that the power supply is stable and properly connected.

- Inspect the cord: Look for any visible damage or wear that might cause interruptions.

- Reset the device: Some tools may require a reset after a power surge or overload.

Performance Issues

- Examine the blade: Make sure it is sharp and correctly aligned.

- Check for obstructions: Clear any debris or material that might hinder smooth operation.

- Lubricate moving parts: Proper lubrication reduces friction and enhances efficiency.

If problems persist after performing these checks, it may be necessary to consult a specialist or refer to detailed guidance to prevent further complications.

Enhancing Performance with Accessory Options

Improving the efficiency and capabilities of cutting tools can be achieved by integrating a range of supplementary components. These enhancements not only broaden the scope of tasks that can be performed but also contribute to achieving finer, more precise results. By selecting and incorporating the right accessories, users can tailor their equipment to better meet specific needs and optimize performance.

For instance, upgrading blades to those designed for particular materials or cutting styles can significantly affect the quality and speed of cuts. Additionally, utilizing attachments like guide rails or dust extraction systems can enhance stability and maintain a cleaner working environment. Exploring various accessory options and understanding their impact on functionality is key to maximizing the potential of any cutting tool.