In the world of power tools, mastering the use of a versatile cutting and grinding device is essential for achieving precision and efficiency in various tasks. This segment will guide you through the essential aspects of handling and operating this indispensable tool effectively.

From setup to maintenance, knowing the proper procedures can significantly impact the quality of your work. Whether you are a novice or an experienced user, understanding the detailed instructions for optimal usage is crucial.

By following comprehensive guidelines, you can ensure both safety and performance while using your tool for various applications. This guide will provide you with a thorough overview of the procedures necessary to harness the full potential of your equipment.

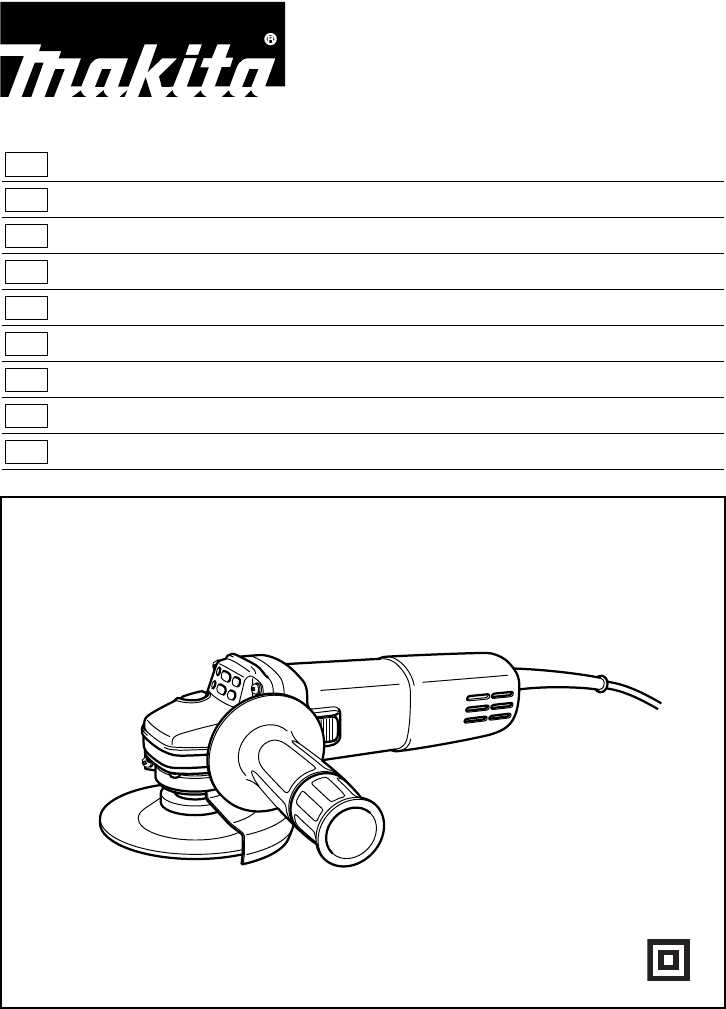

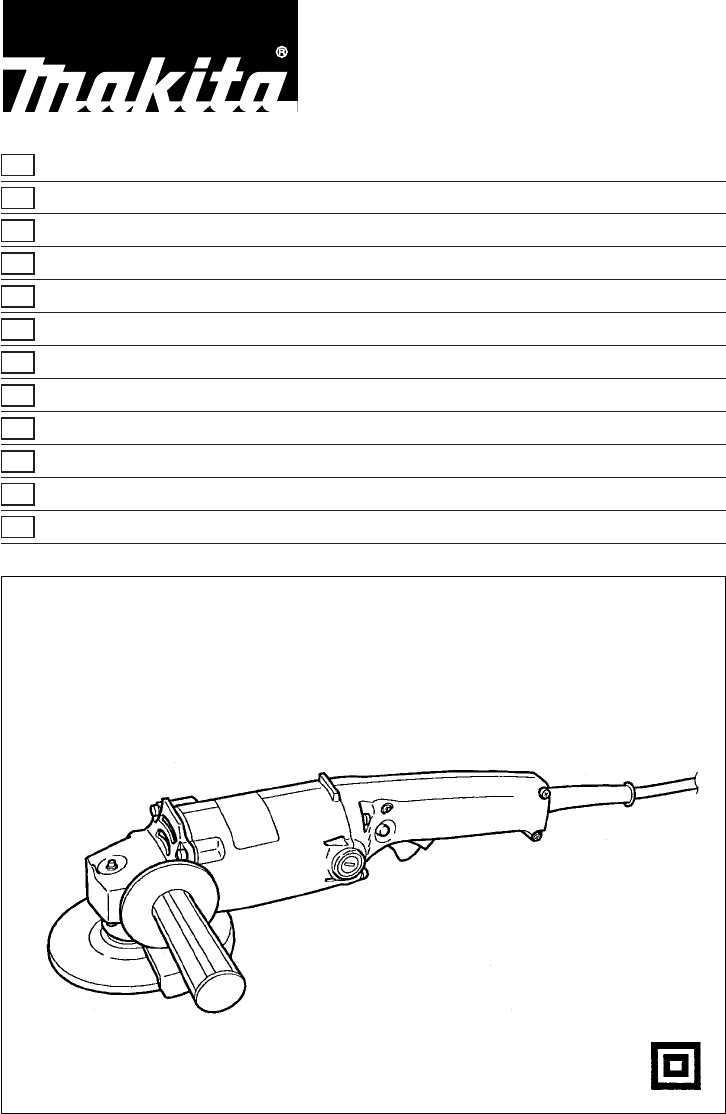

Understanding Your Makita Angle Grinder

Familiarizing yourself with your power tool is essential for achieving optimal performance and ensuring safety. This section will help you gain a deeper understanding of how to effectively operate and maintain your tool. By grasping the key components and functions, you will be better equipped to handle various tasks and troubleshoot any issues that may arise.

Key Components

Your tool comprises several critical parts, each serving a distinct purpose. The main body houses the motor, which powers the device. The attachment area, often featuring a locking mechanism, allows for the secure fitting of different accessories. Additionally, the handle provides control and stability during use, while safety features are designed to protect the user from potential hazards.

Operating Tips

Proper operation involves understanding the correct usage of different settings and accessories. Always ensure that the tool is securely assembled before starting work. Adjust the speed and settings according to the material being worked on, and follow all safety precautions to prevent accidents. Regular maintenance, including cleaning and checking for wear, will extend the life of your tool and keep it functioning smoothly.

Essential Safety Precautions

Ensuring safety while operating power tools is crucial to prevent accidents and injuries. Adhering to proper precautions can significantly reduce the risk associated with their use. This section outlines fundamental practices that should be followed to maintain a safe working environment.

- Always wear appropriate personal protective equipment (PPE) such as safety goggles, gloves, and hearing protection.

- Ensure the workspace is clean and free of obstructions that could pose a hazard.

- Verify that the tool is in good working condition before use. Check for any damage or wear that could affect performance.

- Secure the workpiece firmly to prevent movement during operation.

- Keep hands and other body parts away from moving parts to avoid injuries.

- Never bypass safety features or use the tool for purposes other than those intended.

- Disconnect the tool from the power source when not in use or when making adjustments.

- Follow all manufacturer guidelines and recommendations for operation and maintenance.

By following these essential precautions, you ensure both your safety and the efficiency of the tool’s performance. Always prioritize safety to prevent accidents and achieve the best results in your projects.

Components and Features Overview

Understanding the essential elements and functions of a power tool is crucial for effective and safe operation. This section provides a comprehensive overview of the various parts and features typically found in such a device. By familiarizing yourself with these components, you can better appreciate their roles and optimize the use of the tool for different tasks.

Main Parts

The core of this tool consists of several integral parts that work together to perform its functions. Key components include the motor, which drives the device; the housing, which encloses and protects internal mechanisms; and the handle, which provides control and stability during operation. Additionally, the tool features a guard for safety and an adjustment mechanism for changing the working position or angle of the attachment.

Key Features

Among the notable features are variable speed settings that allow for customization based on the task at hand. The tool may also include a dust extraction system to keep the work area clean and enhance visibility. Ergonomic design elements, such as padded handles and well-placed controls, are intended to reduce user fatigue and increase comfort. Advanced models might offer features like electronic overload protection or quick-change systems for attachments.

Step-by-Step Setup Instructions

Setting up your tool correctly is essential for optimal performance and safety. This guide will walk you through the essential stages of preparing your equipment for use, ensuring that every component is correctly installed and secured. Follow these steps carefully to guarantee a smooth and effective operation.

Preparing the Equipment

Begin by selecting a stable work surface and ensuring that the tool is unplugged from any power source. Inspect the tool for any visible damage or defects before starting the setup process. Gather all necessary accessories and components that came with the tool.

Assembly and Adjustment

First, attach the handle to the designated area on the tool, ensuring it is firmly secured. Next, fit the appropriate accessory onto the spindle, making sure it is aligned correctly. Use the provided tool to tighten any screws or fastenings to secure the accessory in place. Finally, adjust any settings or dials according to the intended application, and double-check all components to confirm they are properly installed and tightened.

Operation Techniques for Optimal Performance

Achieving the best results with your power tool involves more than just basic usage. Proper handling and maintenance are crucial to ensure efficiency and longevity. This section provides valuable insights into how to maximize the effectiveness of your tool while ensuring safety and precision.

- Choose the Right Accessory: Select the appropriate attachment for the task at hand. Different materials and applications require specific tools to achieve optimal results.

- Adjust Speed Settings: Utilize adjustable speed settings to match the material you are working with. Lower speeds are ideal for delicate tasks, while higher speeds are suited for heavy-duty operations.

- Maintain Proper Grip: Ensure a firm and comfortable hold on the tool to enhance control and reduce fatigue. Proper ergonomics contribute to both safety and accuracy.

- Monitor Tool Condition: Regularly inspect your equipment for any signs of wear or damage. Keeping the tool in good condition helps prevent malfunctions and extends its operational lifespan.

- Use Correct Techniques: Employ the right technique for each task. For example, maintain a steady hand and consistent pressure to avoid uneven results or damage to the material.

- Keep Work Area Clean: A tidy workspace enhances visibility and reduces the risk of accidents. Remove debris and obstructions to ensure a safe and efficient working environment.

By following these guidelines, you can ensure that your tool performs at its best, delivering excellent results and operating safely. Regular attention to these practices will contribute to a smoother and more effective work experience.

Maintenance and Care Guidelines

Proper upkeep and attention to your tool are essential for ensuring its longevity and optimal performance. Regular maintenance not only extends the lifespan of the equipment but also ensures it operates safely and efficiently. This section outlines the key procedures and best practices to follow for effective care and upkeep.

Routine Cleaning

Keeping your tool clean is crucial for maintaining its functionality. After each use, remove any dust, debris, or residue from the exterior and vents. Use a dry cloth or a brush to clear away particles. Avoid using water or harsh chemicals, as these can damage the internal components. For more thorough cleaning, refer to the specific guidelines provided by the manufacturer.

Inspection and Replacement

Regularly inspect the equipment for any signs of wear or damage. Check for loose or damaged parts, and ensure that all components are securely fastened. Pay particular attention to areas that experience high levels of stress or friction. Replace worn or broken parts immediately to prevent further damage and maintain safe operation. Refer to the manufacturer’s recommendations for suitable replacement parts and procedures.

Troubleshooting Common Issues

When operating power tools, encountering problems is not uncommon. Understanding how to address these issues effectively can ensure smoother operation and longer tool life. This section provides guidance on resolving frequent challenges that users may face.

- Tool Not Starting

- Check if the tool is properly plugged in or if the battery is charged.

- Inspect the power cord for any visible damage or loose connections.

- Ensure the safety switch is fully engaged.

- Excessive Vibration

- Examine the accessory to make sure it is properly mounted and balanced.

- Look for any wear or damage on the tool’s components that could cause instability.

- Verify that the tool’s housing and internal parts are clean and free of debris.

- Noisy Operation

- Check for loose or damaged parts that might contribute to abnormal noise.

- Ensure that the accessories are in good condition and properly installed.

- Consult the manufacturer’s guidelines for recommended maintenance procedures.

- Overheating

- Allow the tool to cool down before resuming use.

- Ensure proper ventilation and avoid overloading the tool.

- Inspect for any blockages or debris that might impede airflow.

- Inconsistent Performance

- Check for any issues with the power supply or battery charge.

- Ensure that all settings are correctly adjusted according to the task requirements.

- Review the condition of the tool’s internal components and replace any worn parts.