Mastering the art of sewing involves not only creativity but also an in-depth understanding of the equipment at your disposal. The right machine can significantly enhance your efficiency and precision, making it essential to familiarize yourself with all its features and functionalities.

This guide serves as a valuable resource for those looking to delve deeper into the intricacies of operating a professional-grade sewing machine. By exploring its various components and settings, you’ll be able to fully leverage the capabilities of your device, ensuring that each project you undertake is executed with the highest level of craftsmanship.

With detailed explanations and practical tips, this text is designed to support both beginners and experienced users in optimizing their sewing experience. Whether you are adjusting tension settings or exploring advanced stitch options, the insights provided here will empower you to achieve exceptional results.

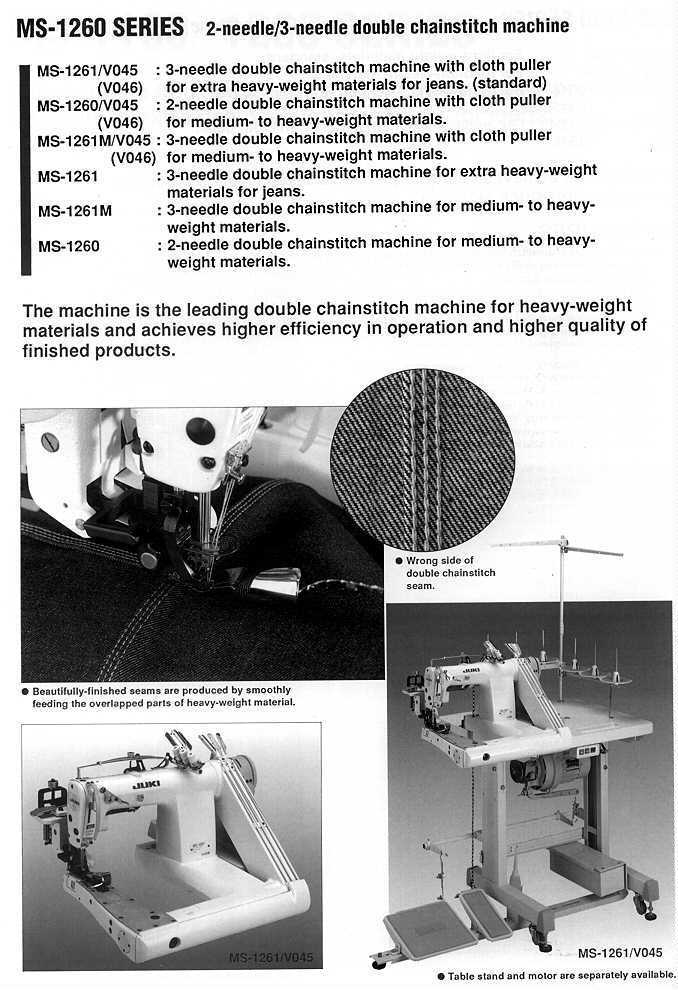

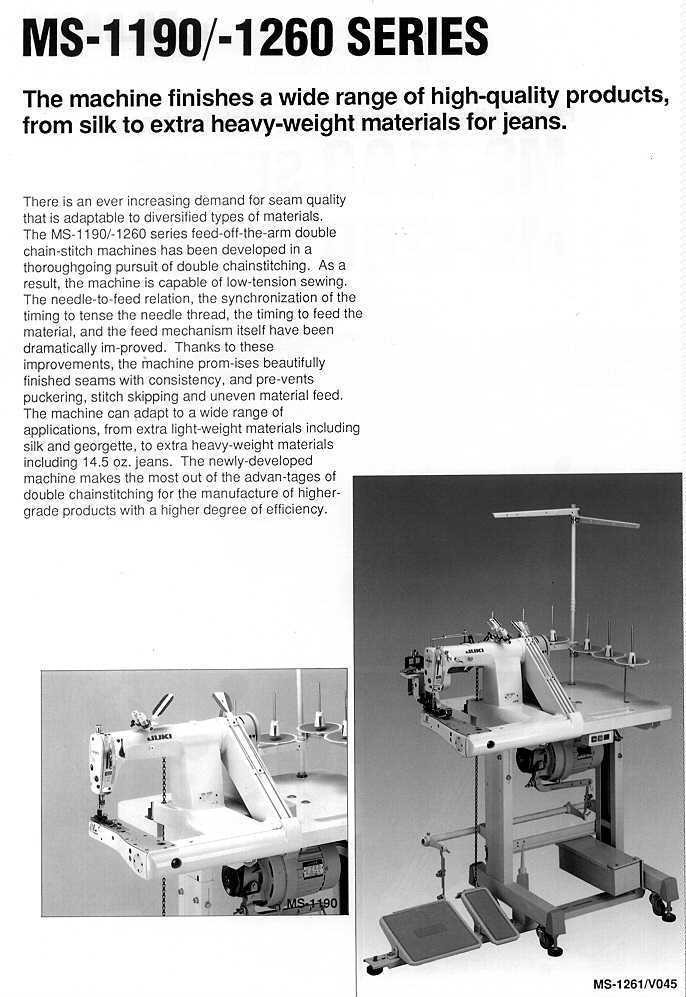

Juki MS-1190 Setup Process

The process of configuring this advanced sewing machine is critical to ensure optimal performance. Proper preparation and assembly are essential for achieving precise and consistent results in your projects.

Step 1: Begin by ensuring that all components are available and in good condition. Carefully unpack the machine and its accessories, making sure that nothing is missing or damaged.

Step 2: Place the unit on a stable, flat surface. This helps to maintain balance during operation and prevents unnecessary movement.

Step 3: Attach the appropriate presser foot for the type of material you will be working with. This step is crucial for ensuring smooth fabric feed and preventing slippage.

Step 4: Thread the machine according to the provided guide, making sure that the thread path is correct to avoid tension issues during sewing. Pay attention to the threading sequence as it can affect stitch quality.

Step 5: Adjust the tension settings to match the fabric and thread you are using. P

Getting Started with Juki MS-1190

Before diving into the operation of your new equipment, it’s essential to familiarize yourself with the key features and setup process. This will ensure that you can use the machine efficiently and effectively from the start. Understanding the initial steps will help you avoid common mistakes and get the most out of your equipment.

Below is a quick overview of what you’ll need to do to prepare your device for its first use:

| Step | Description | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Unpacking | Carefully remove all packaging materials and ensure all components are present. | |||||||||||||||||||

| Setup | Assemble the main parts and accessories following the provided guidelines. | |||||||||||||||||||

| Power Connection | Connect the power cord to a

Essential Maintenance Tips for Optimal PerformanceRegular upkeep is crucial for ensuring that your equipment functions at its best over time. By following a few key practices, you can prevent common issues, extend the lifespan of your machine, and maintain its peak efficiency. Consistent attention to detail during maintenance routines can significantly reduce downtime and repair costs. Routine Cleaning

Maintaining a clean work environment is vital for seamless operation. Dust and debris can accumulate in various parts of the machine, leading to potential malfunctions. It’s important to clean the machine thoroughly, focusing on critical areas that are prone to build-up. Use appropriate tools to remove any residue and ensure all moving parts are free from obstructions. Lubrication of Moving Parts

Proper lubrication is essential for the smooth operation of any mechanical system. Ensure that all moving components are regularly lubricated with the correct type of oil or grease. This helps to minimize friction, reduce wear and tear, and prevent overheating. Regular lubrication not only enhances performance but also prolongs the machine’s overall service life. Common Issues and Troubleshooting Guide

When dealing with industrial sewing equipment, various challenges may arise that can hinder performance. This section outlines common problems that users may encounter and offers practical solutions to ensure smooth operation. Stitching Problems

One of the most frequent issues is irregular stitching, which can result from several factors. Tension imbalances, improper threading, or needle wear can lead to skipped stitches or inconsistent stitch quality. Regular inspection and adjustment of these elements can resolve most stitching-related issues. Machine MalfunctionsOperational malfunctions can occur due to wear and tear or incorrect settings. Issues such as thread breakage, motor failure, or unusual noises often indicate a need for maintenance or part replacement. Following a regular maintenance schedule and ensuring correct settings can prevent most malfunctions.

|