Understanding the intricate functionalities of modern sewing machines is crucial for anyone looking to achieve professional-level results. This guide offers detailed insights into the operational aspects of a high-performance model, designed to enhance efficiency and precision in your projects. Whether you’re an experienced tailor or just beginning, mastering this equipment will significantly improve your crafting experience.

The following sections delve into essential aspects, from setup to troubleshooting, ensuring that you gain the necessary skills to fully utilize the machine’s capabilities. By following these steps, you will be able to execute complex tasks with ease and accuracy.

Explore the advanced features that distinguish this model from others, and learn how to leverage them to create flawless stitches and patterns. This guide is an indispensable resource for maximizing the potential of your sewing machine and elevating your craftsmanship.

Understanding the Basics of the Juki LK-1900

Before diving into the specifics of utilizing your sewing machine, it’s crucial to grasp the foundational concepts that will guide you through its effective operation. This section aims to provide you with a clear understanding of the essential features and functions that you will frequently interact with. Familiarizing yourself with these basics will ensure a smoother experience and more precise results as you work on your projects.

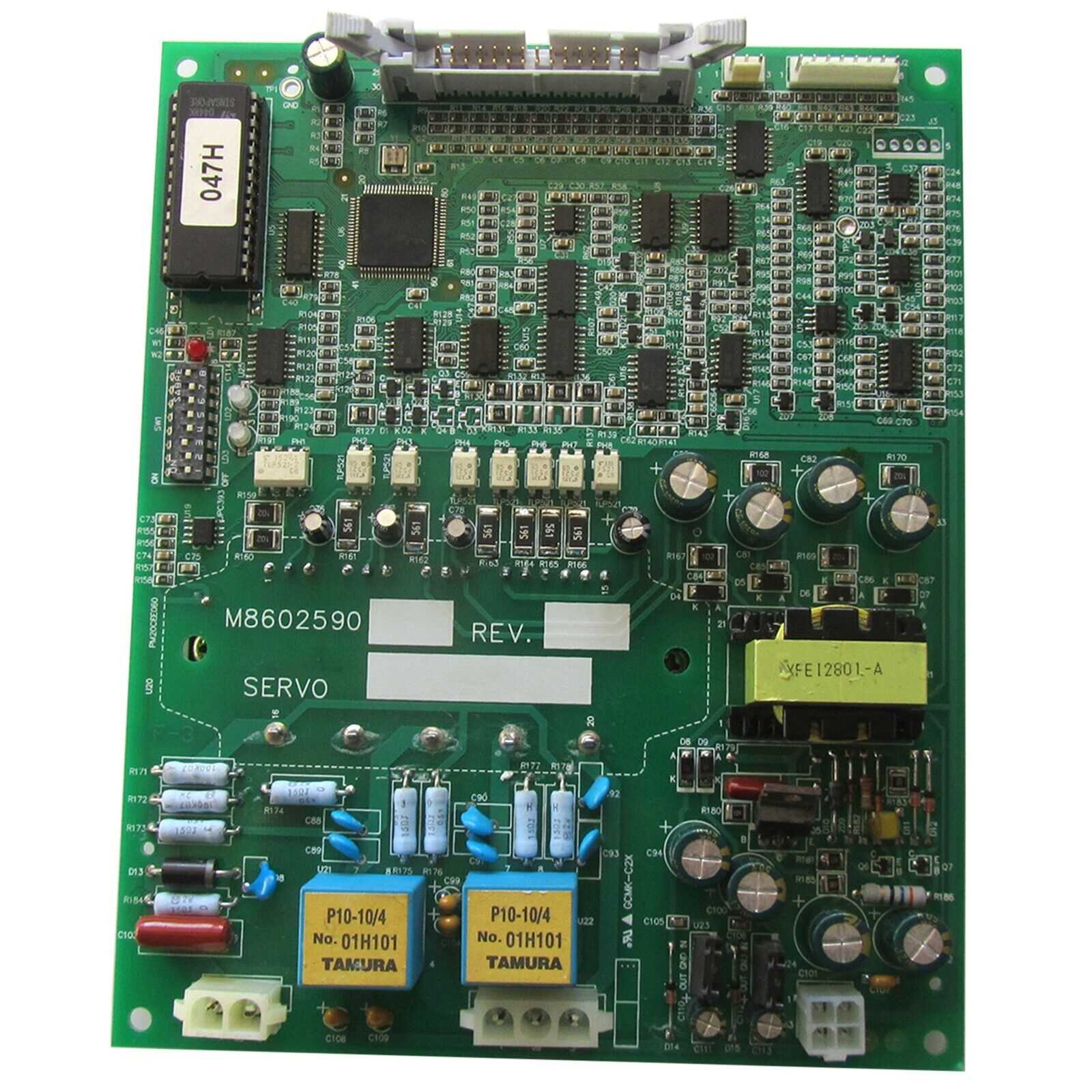

Core Components

The machine is designed with several key components that work together to produce consistent and high-quality stitches. Understanding the role of each part will help you in troubleshooting issues and maintaining the machine efficiently. The needle, the thread system, and the feed mechanism are among the most critical elements that you will need to become comfortable with.

Operational Mechanics

Another vital aspect to understand is the operational mechanics of the device. This includes how the machine is powered, the controls available for adjusting speed and stitch patterns, and the process for setting up the machine for different types of fabrics. A solid grasp of these mechanics will enable you to fully leverage the capabilities of the machine, ensuring your projects are completed with precision and speed.

Step-by-Step Setup Guide for Beginners

Setting up your machine correctly from the start ensures smooth operation and high-quality results. This guide provides clear, concise instructions to help you assemble and configure your equipment efficiently. Follow each step to establish a solid foundation for your future projects.

Step 1: Unboxing and Inspecting Components

Carefully remove all parts from the packaging and lay them out on a clean, flat surface. Ensure that each component is present and free from damage. Check the user guide included for a list of items that should be in the box.

Step 2: Assembling the Stand

Begin by assembling the stand according to the provided instructions. Tighten all screws securely to ensure stability. Position the stand in a well-lit area with sufficient space around it for comfortable use.

Step 3: Mounting the Machine

Once the stand is assembled, place the machine on top and align it with the mounting holes. Secure it using the provided bolts, making sure it is level and firmly attached. This will prevent any wobbling during operation.

Step 4: Installing the Needle and Presser Foot

Insert the needle into the designated slot and tighten the screw to hold it in place. Attach the presser foot by aligning it with the shank and securing it with the lever. Double-check that both components are installed correctly.

Step 5: Threading the Machine

Follow the threading path as indicated on the machine. Start from the spool pin and guide the thread through each point until it reaches the needle. Ensure that the thread is properly tensioned to avoid issues during sewing.

Step 6: Winding the Bobbin

Place the bobbin on the winder and thread it according to the machine’s diagram. Engage the winder and press the foot pedal to start winding. Once the bobbin is full, cut the thread and place it in the bobbin case.

Step 7: Testing the Setup

Before starting your first project, test the setup by sewing a few stitches on a scrap piece of fabric. This allows you to check the stitching quality and make any necessary adjustments. Ensure the stitches are even and the machine operates smoothly.

By following these steps, you’ll be ready to start your projects with confidence, knowing that your equipment is properly set up and ready to deliver excellent results.

Key Features and Functions Overview

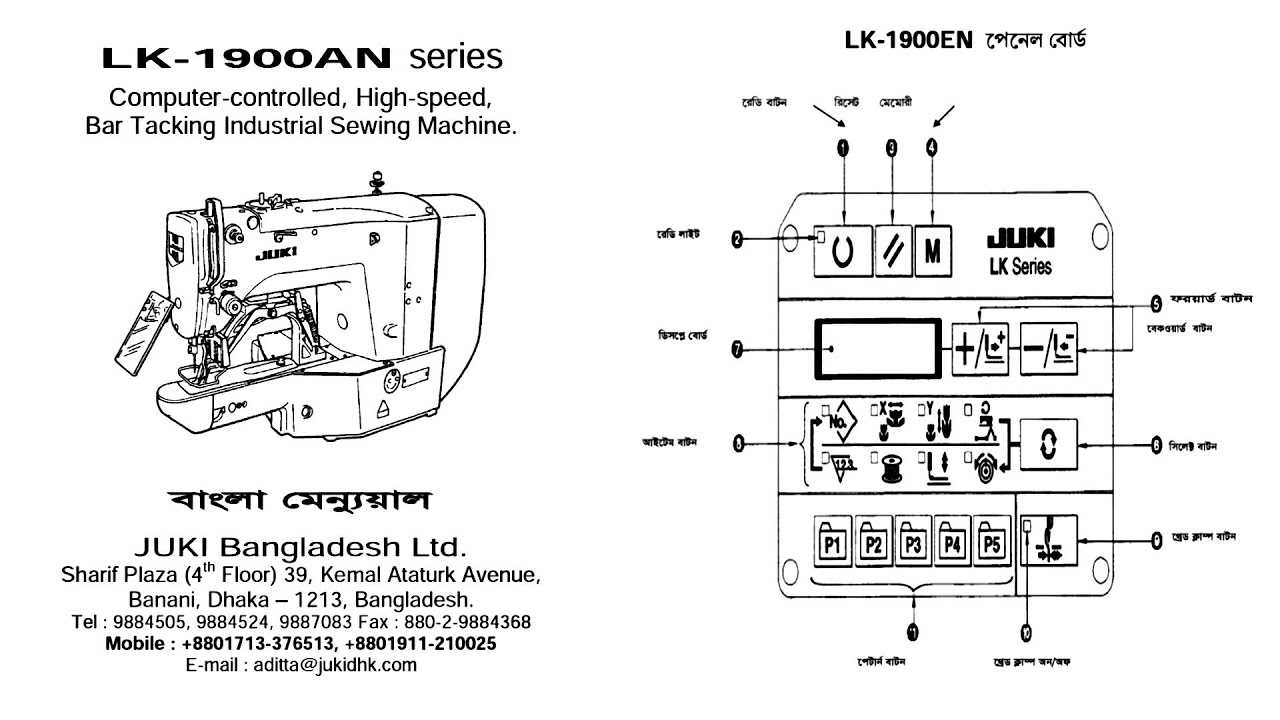

This section provides an in-depth exploration of the essential capabilities and operational elements of the advanced stitching equipment. It offers a clear understanding of the machine’s functionalities, designed to enhance productivity and ensure precision in textile projects.

- High-Speed Performance: The equipment is engineered to deliver rapid sewing, optimizing efficiency without compromising stitch quality.

- Automatic Thread Trimming: Integrated mechanisms allow for seamless trimming of threads after each operation, reducing manual intervention and time.

- Adjustable Stitch Length: Users can easily modify the stitch length to suit various fabrics and project requirements, providing versatility in sewing applications.

- Programmable Patterns: The machine offers the ability to store and recall multiple stitching patterns, enabling consistency across repeated tasks.

- User-Friendly Interface: A straightforward control panel provides intuitive access to all functions, simplifying the process of setting and adjusting parameters.

- Durability and Reliability: Built with robust materials and cutting-edge technology, the machine ensures long-term use with minimal maintenance.

Troubleshooting Common Issues and Fixes

Every complex machine can present challenges from time to time. Understanding how to diagnose and address common problems is essential for smooth operation. This section offers guidance on identifying frequent issues and applying effective solutions to maintain optimal performance.

Machine Stopping Unexpectedly: If the device halts suddenly during operation, check the power supply and ensure it is securely connected. Inspect the machine for any obstructions or jammed components that may be causing the interruption.

Thread Breakage: Broken threads can be a result of improper threading or tension settings. Verify that the thread path is correctly aligned and adjust the tension according to the type of fabric being used. Also, check for any damage to the thread or needle.

Unusual Noises: Unusual sounds often indicate a need for lubrication or possible misalignment of moving parts. Ensure all moving components are adequately lubricated and consult the alignment guide to correct any discrepancies.

Poor Stitch Quality: If the stitches are inconsistent, the issue may lie with the needle or thread tension. Replace the needle with a new one and adjust the tension settings to achieve better stitch formation. Additionally, ensure that the fabric is correctly positioned and supported.

Machine Not Responding: When the machine fails to respond to controls, check the power connection and ensure that all cables are properly connected. Restart the machine to reset the system and verify that there are no software issues affecting its operation.

Maintenance Tips for Long-Lasting Performance

Proper upkeep is essential to ensure the longevity and reliable operation of your sewing machine. Regular maintenance not only extends the lifespan of the equipment but also helps in maintaining optimal performance and preventing unexpected breakdowns. By adhering to a few essential practices, you can keep your machine running smoothly and efficiently.

- Regular Cleaning: Dust and debris can accumulate and affect the machine’s functionality. Clean the exterior and interior parts frequently using a soft brush or a vacuum cleaner with a brush attachment. Ensure that you remove lint and thread scraps from the bobbin case and other moving parts.

- Lubrication: Keep the machine well-lubricated by applying the recommended oil to moving parts. Follow the manufacturer’s guidelines for oiling intervals and use only the specified type of lubricant to avoid damage.

- Check Tension Settings: Regularly inspect and adjust the thread tension settings to ensure consistent stitching quality. Incorrect tension can lead to thread breakage or uneven stitches.

- Replace Worn Parts: Inspect components such as needles, presser feet, and belts for signs of wear and tear. Replace any worn or damaged parts promptly to avoid impacting the machine’s performance.

- Proper Storage: Store the machine in a clean, dry place when not in use. Cover it with a dust cover or cloth to protect it from dust and environmental factors.

- Professional Servicing: Schedule periodic check-ups with a qualified technician to ensure the machine is functioning correctly and to address any issues before they become major problems.

By incorporating these maintenance practices into your routine, you can enjoy consistent performance and extend the life of your sewing machine, ensuring it remains a reliable tool for your projects.

Enhancing Efficiency with Advanced Techniques

Maximizing productivity in any operation often requires implementing sophisticated methods designed to streamline processes and reduce waste. By leveraging advanced techniques, one can significantly boost performance and achieve superior results. These methods focus on refining workflows, optimizing equipment usage, and integrating technology to enhance overall efficiency.

Streamlining Workflow Processes

Optimizing workflow processes is essential for achieving peak efficiency. Techniques such as process mapping and time-motion studies can help identify bottlenecks and areas for improvement. By reconfiguring workflows and reducing unnecessary steps, operations can become more fluid and less prone to delays.

Leveraging Technology for Efficiency

Incorporating cutting-edge technology can dramatically improve operational efficiency. Advanced software solutions and automation tools facilitate more accurate and faster production. Technology also enables better monitoring and control, allowing for real-time adjustments and improved quality management.

| Technique | Description | Benefits |

|---|---|---|

| Process Mapping | Visual representation of workflows | Identifies inefficiencies and areas for improvement |

| Time-Motion Studies | Analysis of task performance | Optimizes task efficiency and reduces time wastage |

| Automation | Use of machines and software to perform tasks | Increases speed and accuracy, reduces manual errors |

| Real-Time Monitoring | Continuous tracking of processes | Allows for immediate adjustments and quality control |

By applying these advanced methods, operations can become more efficient, leading to higher productivity and better outcomes. Embracing these strategies is key to staying competitive and achieving long-term success.