Mastering a high-performance sewing machine can elevate your craft to new levels of precision and efficiency. This detailed guide is designed to help users navigate the complex features and capabilities of a robust, industrial-grade machine, providing step-by-step instructions for optimal usage.

Understanding the various components and their functions is essential for maximizing productivity and ensuring long-term durability. In this guide, each part of the machine is meticulously explained, allowing both beginners and experienced operators to gain a deeper understanding of its operation.

From threading techniques to maintenance tips, every aspect is covered to ensure smooth and trouble-free sewing. Whether you’re dealing with thick fabrics or intricate patterns, this resource offers valuable insights to help you achieve professional results with ease.

Understanding the Features of This Advanced Sewing Machine

Grasping the essential attributes of this sophisticated sewing machine is key to fully leveraging its capabilities. This section provides an in-depth exploration of the primary functionalities, offering insights into how each feature enhances the machine’s performance and usability. With a focus on user experience, we’ll break down the core components that make this tool a reliable and versatile choice for various sewing tasks.

Core Functionalities

This high-performance sewing machine is equipped with a range of functionalities designed to improve accuracy and efficiency. Here are some of the most noteworthy features:

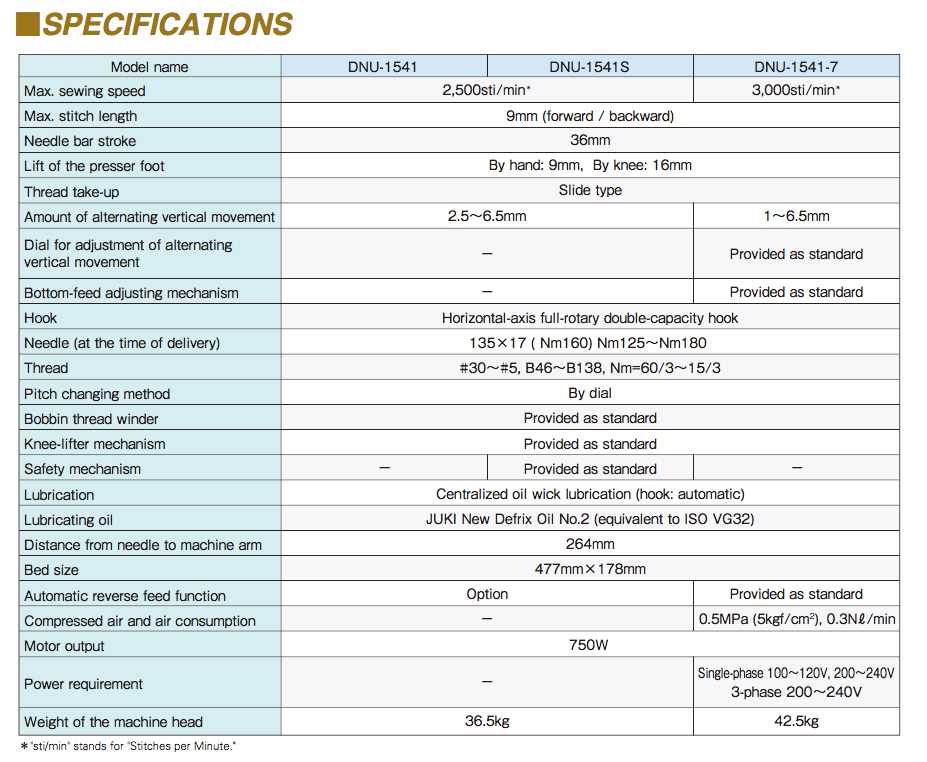

- Walking Foot Mechanism: The walking foot mechanism ensures consistent fabric handling, even with multiple layers, minimizing the risk of slippage and maintaining stitch quality.

- Adjustable Stitch Length: A convenient dial allows for precise control over stitch length, enabling customization to suit different fabric types and project requirements.

- High-Speed Operation: Capable of operating at high speeds, this machine delivers rapid and consistent stitching, making it ideal for both large-scale and detailed work.

- Safety Clutch Device: The built-in safety clutch device prevents damage to the machine in the event of a thread jam, protecting the internal components and reducing downtime.

Additional Features

Beyond the core functionalities, there are several additional features that enhance the machine’s usability and convenience:

- Large Workspace: A spacious work area provides ample room for handling bulky fabrics, making it easier to manage large projects.

- Reverse Stitch Lever: The reverse stitch lever allows for easy reinforcement of seams, ensuring durability and strength where needed.

- Adjustable Presser Foot Pressure: The pressure of the presser foot can be adjusted to accommodate various fabric thicknesses, ensuring optimal feed and stitch consistency.

Understanding these features will help users maximize the potential of their sewing machine, achieving professional-quality results with greater ease and efficiency.

Setting Up Your Machine for the First Time

Getting your new sewing machine ready is a crucial first step to ensure it operates smoothly and efficiently. This process involves a series of well-organized tasks that, when done correctly, will help avoid common issues and extend the lifespan of your equipment. Follow the steps below carefully to set up your machine correctly.

-

Unpacking and Inspection: Begin by carefully removing the machine from its packaging. Inspect it thoroughly for any signs of damage during transit. Make sure all the necessary components and accessories are included.

-

Positioning: Place the machine on a stable, level surface that can support its weight. Ensure there is adequate lighting and space around the machine for easy maneuvering of fabrics.

-

Power Connection: Connect the power cord to a reliable power outlet. Double-check that the voltage matches the requirements specified for your machine. Switch on the power to test that the machine receives electricity properly.

-

Installing the Needle: Select the appropriate needle size for your fabric type. Insert the needle into the holder, ensuring it is fully seated and securely tightened.

-

Threading: Follow the threading path, carefully guiding the thread through each hook, guide, and tension mechanism. Make sure the thread is tensioned correctly to avoid skipped stitches or thread breakage.

-

Bobbin Winding and Placement: Wind the bobbin with your desired thread and place it into the bobbin case. Ensure the bobbin thread feeds correctly without any resistance.

-

Adjusting Tension Settings: Fine-tune the upper and lower thread tension settings to match the fabric you plan to sew. This adjustment is crucial for creating balanced stitches.

-

Testing: Run a few test stitches on a scrap piece of fabric similar to your project material. This will allow you to check the stitch quality and make any final adjustments before starting your work.

Once all these steps are completed, your machine should be ready to use. Regular maintenance and correct setup each time will ensure smooth operation and high-quality results.

Mastering Basic Stitches on the Juki DNU-1541S

Understanding the foundational techniques for sewing is crucial for achieving precise and durable results. This section will guide you through essential stitching methods, ensuring that you can confidently handle a wide range of fabric types and thicknesses. By honing these basic skills, you’ll be well-prepared for more complex sewing projects.

- Straight Stitch: The most fundamental stitch, ideal for seams and topstitching. Ensure even tension and proper alignment to create strong and straight lines.

- Backstitch: Used to secure the beginning and end of seams, this stitch reinforces your work, preventing unraveling.

- Zigzag Stitch: Perfect for preventing fraying on raw edges and for sewing stretch fabrics. Adjust the width and length to suit different materials.

- Overcast Stitch: A must for finishing edges, this stitch wraps the thread around the fabric edge, creating a clean, professional finish.

- Basting Stitch: This long stitch is temporary and is used for holding pieces together before final stitching. It’s easily removable once the permanent seam is in place.

Practicing these stitches will build your confidence and provide the foundation needed for more advanced techniques. Mastering them is the first step toward crafting high-quality, durable projects.

Troubleshooting Common Issues with the Juki DNU-1541S

Even the most reliable sewing equipment can occasionally encounter challenges during operation. Understanding how to quickly identify and resolve these common problems is essential for maintaining smooth and efficient workflow. Below, we will explore practical solutions to frequent issues that may arise, ensuring that your machine continues to perform at its best.

Skipped Stitches

If you notice gaps in your stitching, the first step is to examine the needle. A bent or dull needle often causes skipped stitches. Ensure that the needle is inserted correctly, with the flat side facing the proper direction. Additionally, verify that the needle size is appropriate for the fabric and thread in use.

Thread Breakage

Frequent thread snapping can disrupt your work and is usually linked to tension problems. Begin by checking the upper tension; it may be set too high, causing excessive strain on the thread. Also, inspect the thread path for any obstructions or rough spots that could be causing friction.

Uneven Stitching

Inconsistent stitch length or tension can result from several factors. First, inspect the bobbin case to ensure it is properly seated and free of lint or debris. Also, check the feed dog to confirm it is engaging the fabric evenly. If the problem persists, adjusting the presser foot pressure may help stabilize the fabric movement.

Machine Jamming

A sudden halt during sewing can indicate a jam. To resolve this, turn off the machine and remove the fabric. Examine the needle plate and bobbin area for any tangled thread or fabric pieces. Carefully clean the area, and rethread the machine, ensuring all components are aligned correctly before resuming operation.

Irregular Noise

Unusual sounds often signal a need for maintenance. Ensure that all screws and fasteners are tight. Apply a few drops of oil to the specified lubrication points to reduce friction. If the noise persists, it may be time to seek professional servicing to prevent further damage.

By addressing these issues promptly, you can keep your sewing equipment in optimal condition, reducing downtime and ensuring high-quality results in every project.

Maintaining and Cleaning Your Sewing Machine

Proper upkeep and cleanliness are essential for ensuring the longevity and performance of your sewing equipment. Regular maintenance prevents wear and tear, while thorough cleaning keeps the machine running smoothly and efficiently.

Daily Maintenance: After each use, it’s crucial to remove dust, lint, and any stray threads. Begin by turning off the power and disconnecting the device from the power source. Use a soft brush to clean around the needle plate and bobbin area. Make sure to check for any debris that may have accumulated in the feed dogs and tension discs.

Oiling: Lubrication is necessary to maintain the smooth operation of moving parts. Apply a few drops of oil specifically designed for sewing devices to the recommended spots. Always follow the guidelines for how much oil to use and where to apply it. Over-oiling can lead to unnecessary buildup, while under-oiling can cause friction and damage.

Weekly Deep Cleaning: At least once a week, or after prolonged use, it’s recommended to perform a more detailed cleaning. Remove the needle plate, bobbin case, and other easily detachable components. Clean each part separately, ensuring no lint or dirt is left behind. Reassemble carefully, ensuring all parts are securely in place before use.

Checking the Tension: Maintaining proper thread tension is key to achieving consistent stitches. Regularly inspect the tension settings and adjust them as needed. Clean the tension discs to remove any thread fragments or dust that might affect performance.

Professional Servicing: Despite regular upkeep, it’s important to have the machine serviced by a professional periodically. A qualified technician can identify and fix issues that might not be visible during routine maintenance, ensuring the equipment remains in optimal condition.

By following these steps, you ensure that your sewing device remains reliable, producing high-quality work for years to come.

Advanced Techniques for the Juki DNU-1541S

Exploring sophisticated methods can significantly enhance the performance of your industrial sewing machine. Mastering these techniques allows for improved efficiency, precision, and creativity in various fabric projects. From adjusting settings to implementing specific practices, these advanced strategies can elevate your sewing experience to new heights.

Optimizing Tension Settings

Fine-tuning the tension settings is crucial for achieving flawless stitches. Understanding the relationship between thread type and tension will allow you to adjust accordingly based on the fabric being used. Conducting tests on scrap materials can help identify the optimal tension, ensuring even and secure seams without puckering or thread breakage.

Utilizing Specialty Feet and Attachments

Incorporating various presser feet and attachments can open up a world of creative possibilities. Specialty feet, such as walking feet or zipper feet, enhance the functionality of your machine, enabling you to tackle a wider range of projects. Experimenting with different attachments can also help improve stitch accuracy and efficiency, leading to more professional results.